Automatic labeling device

A labeling and labeling technology, applied in the directions of labels, labeling machines, packaging, etc., can solve the problems of deformation, falling off, and weak label sticking of packaging boxes, and achieve the effect of improving production efficiency, high reliability, and reliable labeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

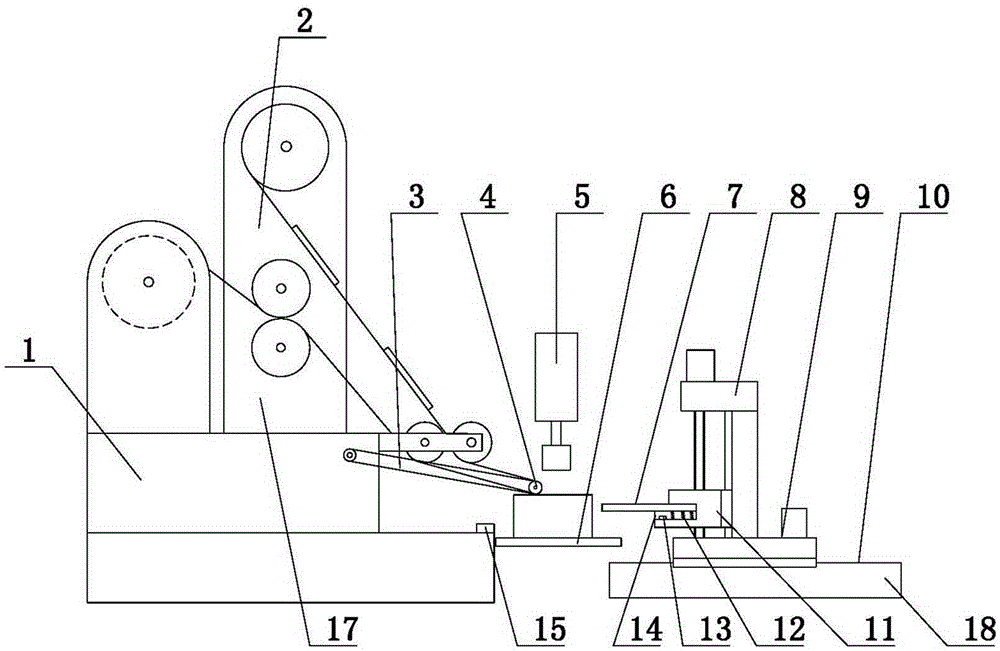

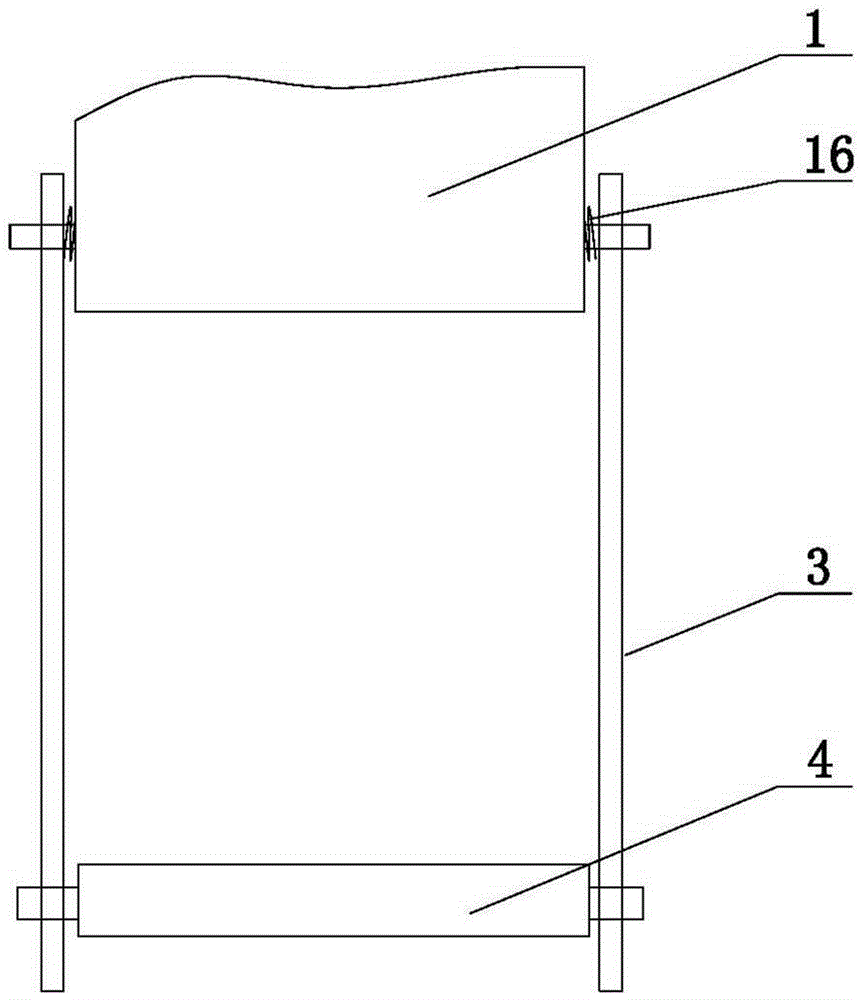

[0013] The present invention includes a labeling mechanism 2 and an auxiliary mechanism 10, and is characterized in that: the labeling mechanism 2 includes a labeling frame 1, an unwinding mechanism 17 is arranged on the labeling frame 1, and the side of the labeling frame 1 is arranged There is a label peeling rod 4 matched with the unwinding mechanism 17, the label peeling rod 4 is arranged at the end of a peeling frame 3, the other end of the peeling frame 3 is hinged with the labeling frame 1, and a torsion spring 16 is arranged at the hinge point ; The labeling frame 1 is provided with a pressure head 5 corresponding to the end of the label peeling bar 4, and a transmission belt 6 is provided corresponding to the pressure head 5; the auxiliary mechanism 10 includes an auxiliary frame 18, and the auxiliary frame 18 A horizontal movement mechanism 9 is arranged on the top, and a support body 11 is arranged on the horizontal movement mechanism 9 through a vertical movement me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com