Welding rod packaging box

A packaging box and welding rod technology, which is applied in the directions of packaging, transportation, packaging, closing, etc., can solve the problems of easy falling of welding rods, inconvenient use, exposure of welding rods, etc., and achieve the benefits of popularization, convenient carrying and time saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

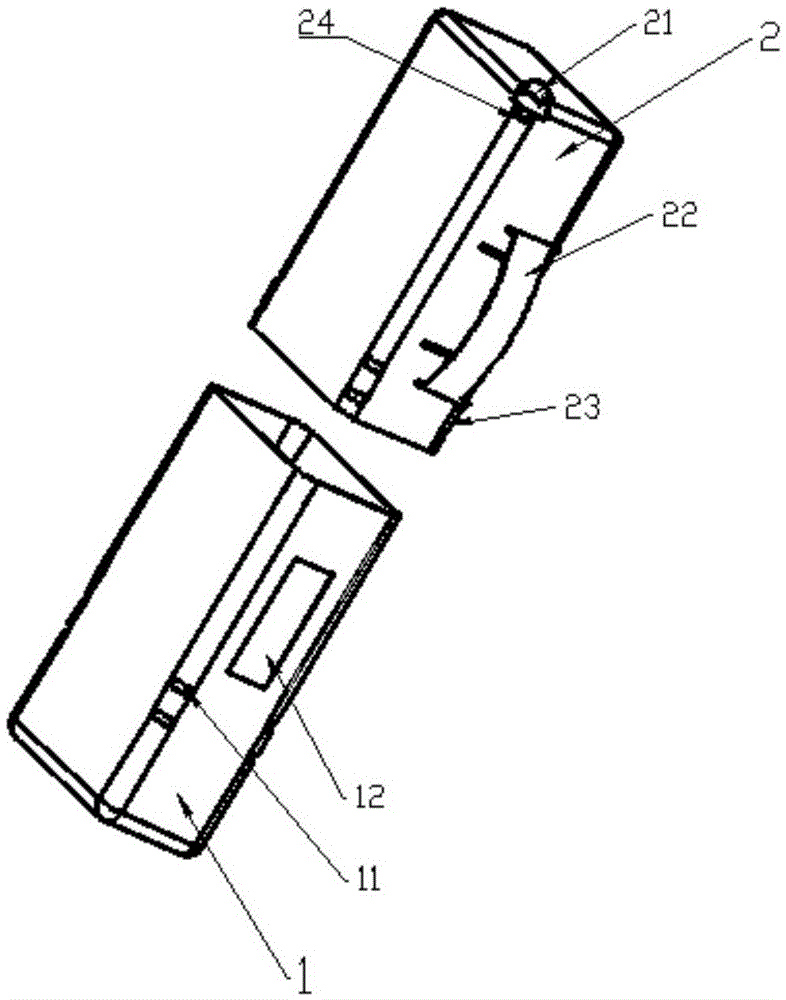

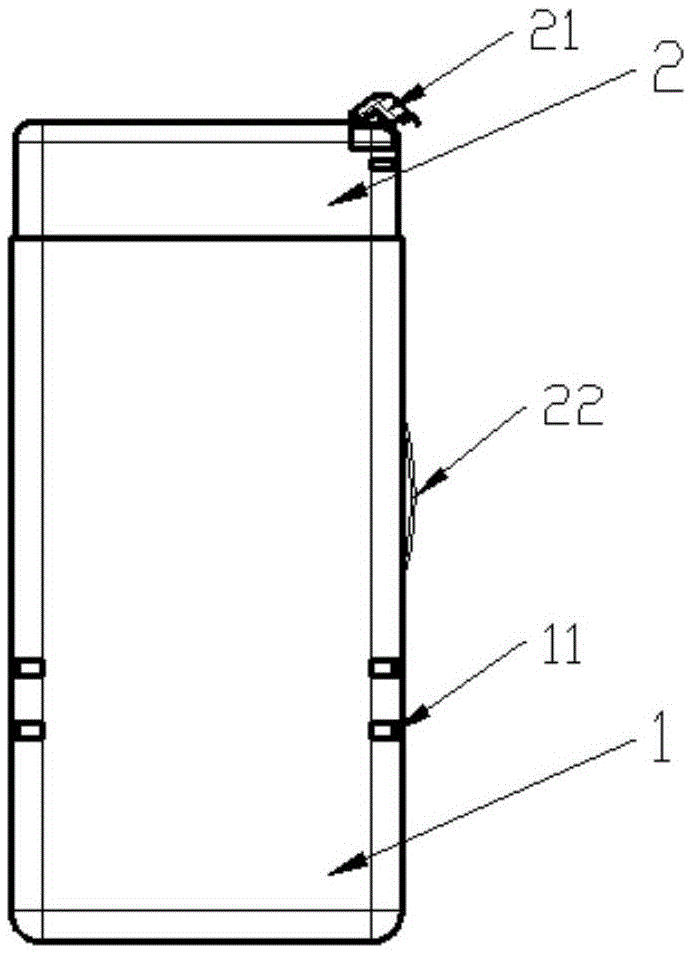

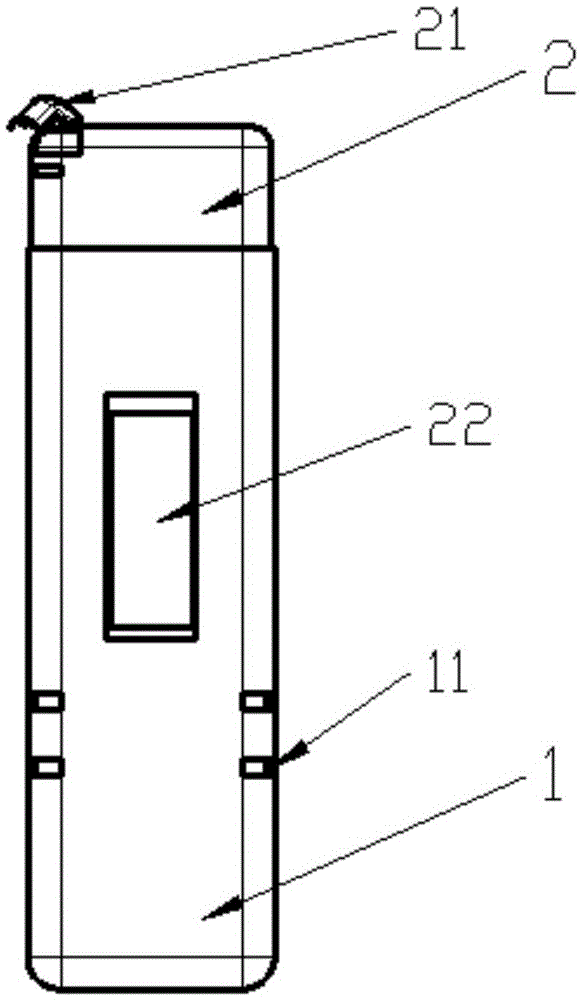

[0016] Figure 1-Figure 3 It shows a welding rod packaging box of the present invention, including a first body 1 and a second body 2, both of which are rectangular parallelepipeds with one end open, wherein the first body 1 is provided with a snap-fit Position 11 and through hole 12, the engaging position 11 is located on the four sides of the first body 1, the through hole 12 is located on the side of the first body, and the second body 2 is provided with a box cover 21, a handle 22, and engaging convex teeth 23 and protrusion 24, the box cover 21 is located at one corner of the top surface of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap