Transporting device and method for nuclear power station open thin-wall container assemblies

A thin-walled container and transportation method technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., to solve the problem of eccentric gravity, avoid deformation and damage, and ensure the synchronization of transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

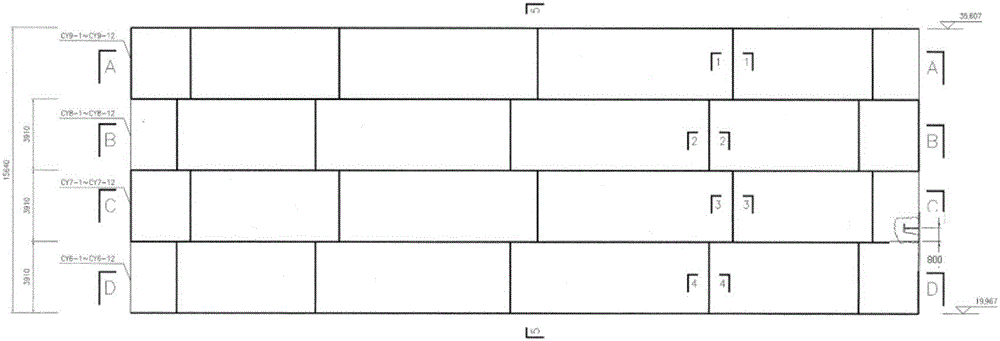

[0070] The open thin-walled container is a cylindrical container with an inner diameter of 43.0m, a height of 15.64m, and a wall thickness of 52mm. It is made of 48 steel plates made of SA-738Gr.B. For protectors and reinforced steel wire ropes, the transportation weight is calculated as 1,000 tons. Structural diagram such as figure 1 shown.

[0071] The means of transport in this application include:

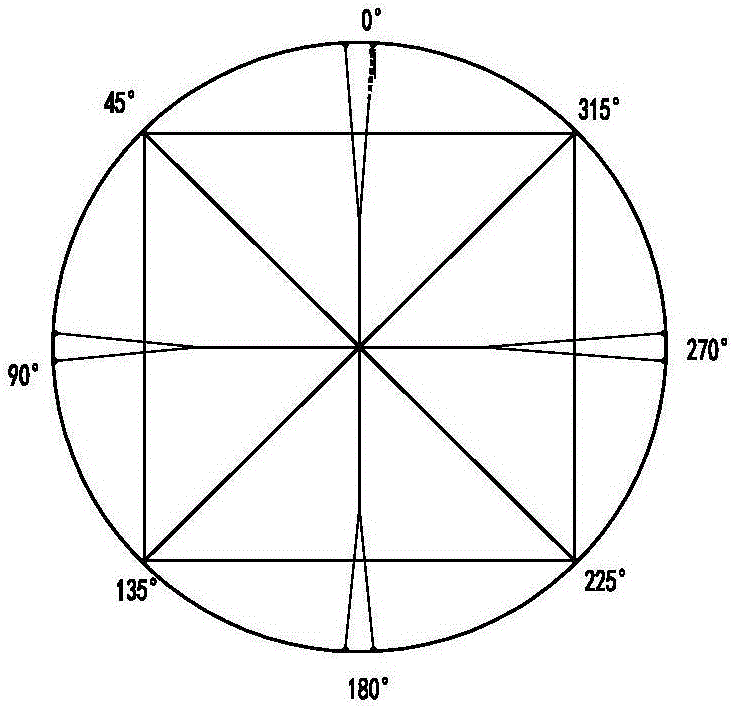

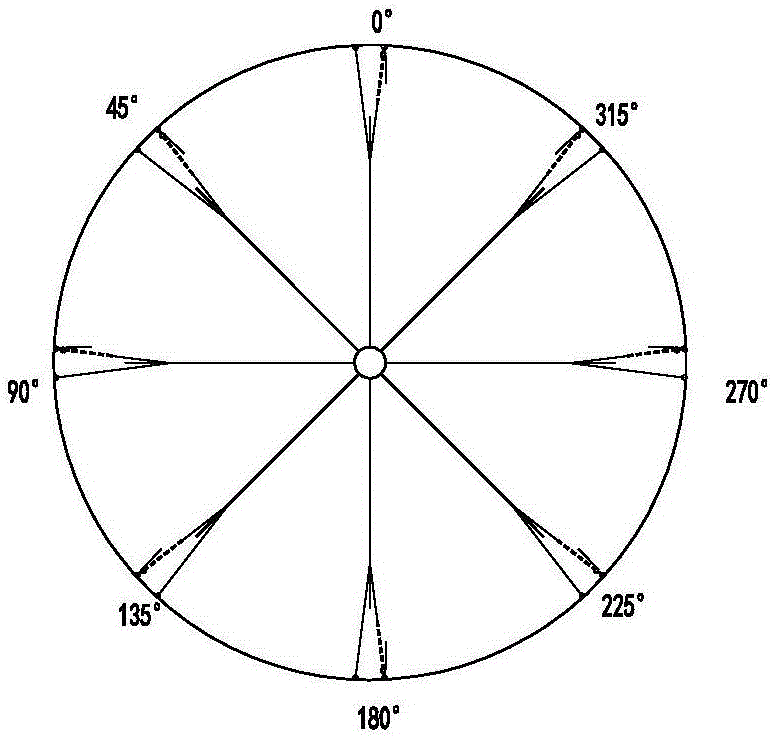

[0072] At least two cloud-shaped tracks 2 laid on the ground, transport vehicles 1 move on the cloud-shaped tracks 2, each transport vehicle 1 is used to support the bottom of the thin-walled container, and two transport vehicles 1 are set on one cloud-shaped track;

[0073] The controller, the controller is separately connected with each transport vehicle; the forward, stop a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com