Automatic cable twisting and winding production line and method thereof for precisely controlling pitch

A production line and twisting technology, which is applied in the field of automatic cable twisting production line and its precise pitch control, can solve problems such as bulging, increased twisting stress, and restricting the development of winding machines, so as to ensure accuracy, output stability, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Attached below figure 1 to attach Figure 22 The present invention will be described in detail.

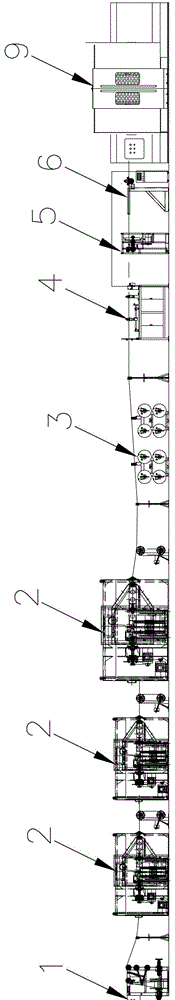

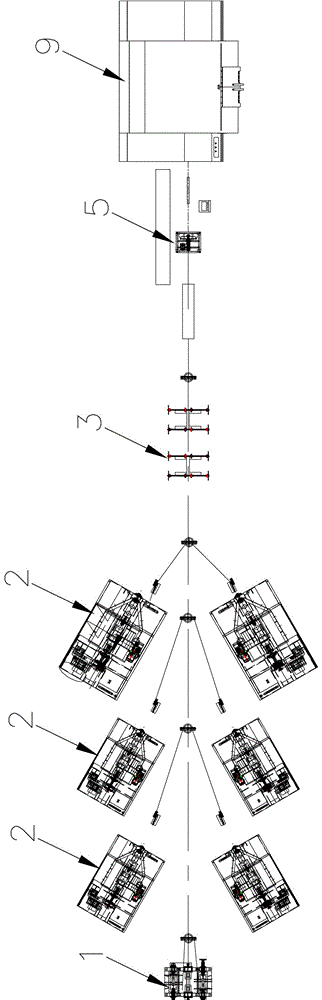

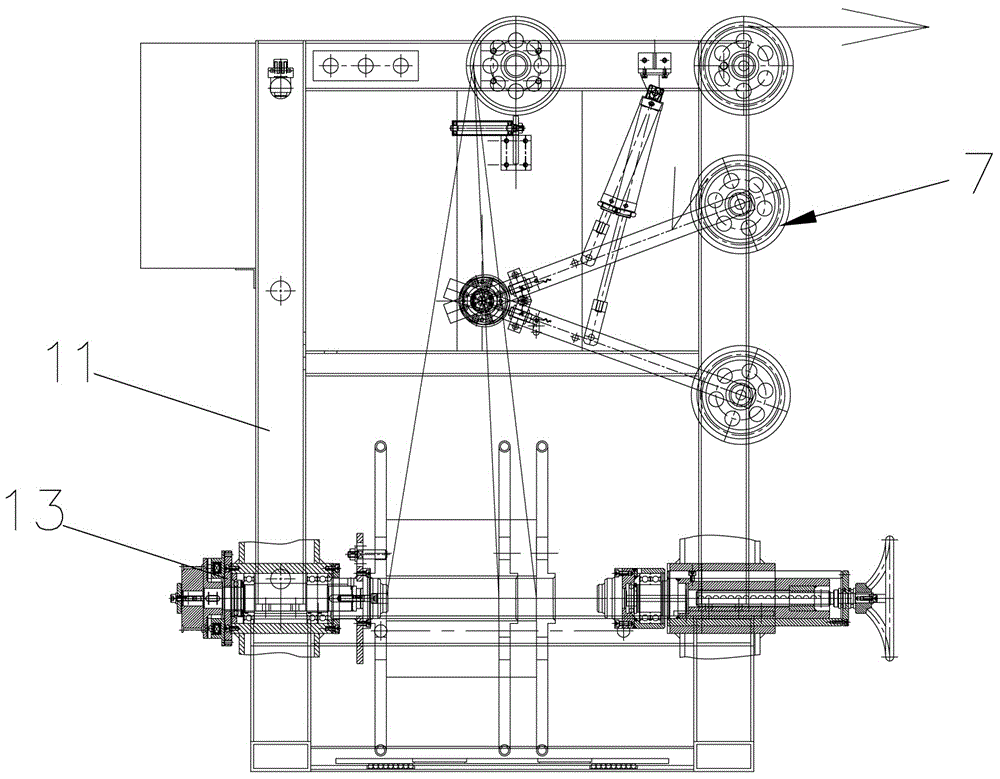

[0046] An automatic cable twisting production line of the present invention includes an active pay-off machine 1, the output end of the active pay-off machine 1 is sequentially provided with a back-twisting pay-off machine 2, a wire gathering device 4, a packaging material device 5, a storage Belt device 6 and winding machine 9; active pay-off machine 1 and back-twisting pay-off machine 2 release the wire respectively, and said back-twist pay-off machine 2 generally can be provided with multiple sets according to the needs of forming wire, for example: if forming The cable includes 8 wires, and the corresponding number of wires can be achieved by increasing the active pay-off machine 1 or the back-twisting pay-off machine 2; multiple wires pass through the wire collection device 4 to form a wire bundle, and the winding machine 9 rotates the wire bundle Twisted forming, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com