Torque steel wire rope coiling block preventing joint of steel wire rope from being rubbed off

A technology of wire rope joints and wire rope reels, which is applied in the field of spring torque winding wire rope reels, can solve the problems of strip breaking, damage, and strip deviation, etc., to reduce inertial impact, improve product quality, and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments.

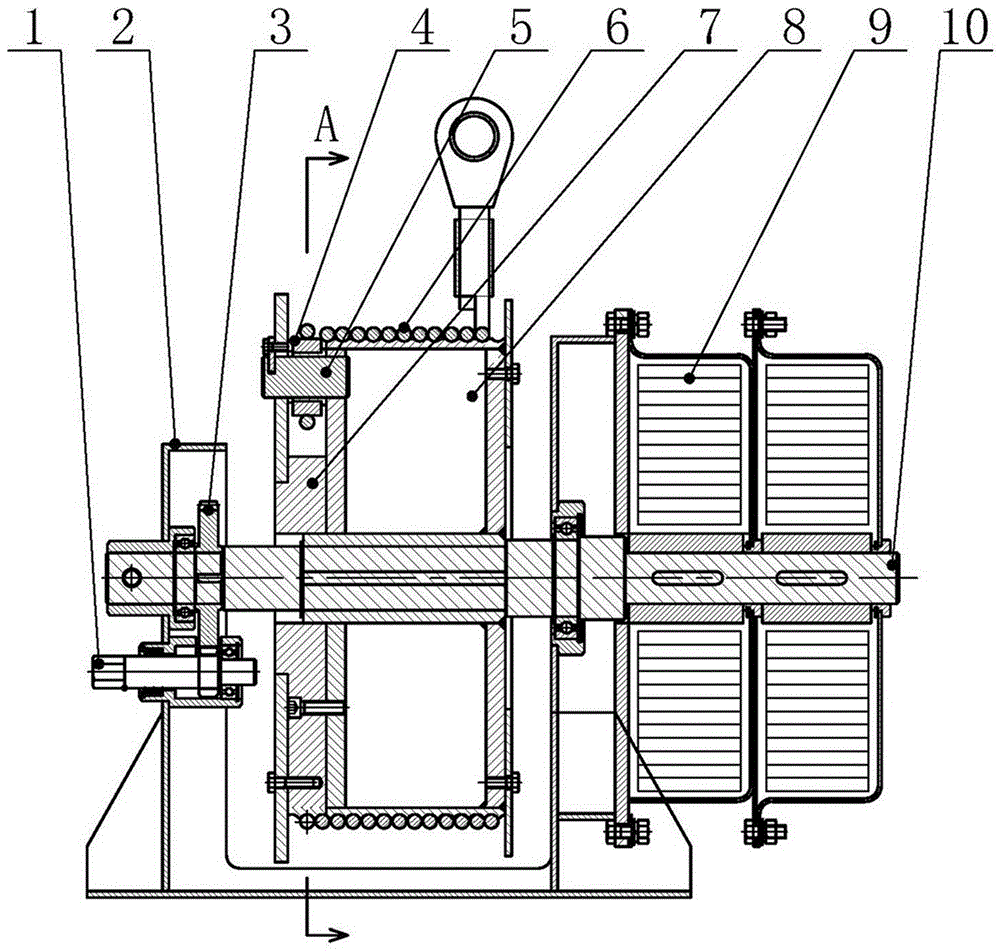

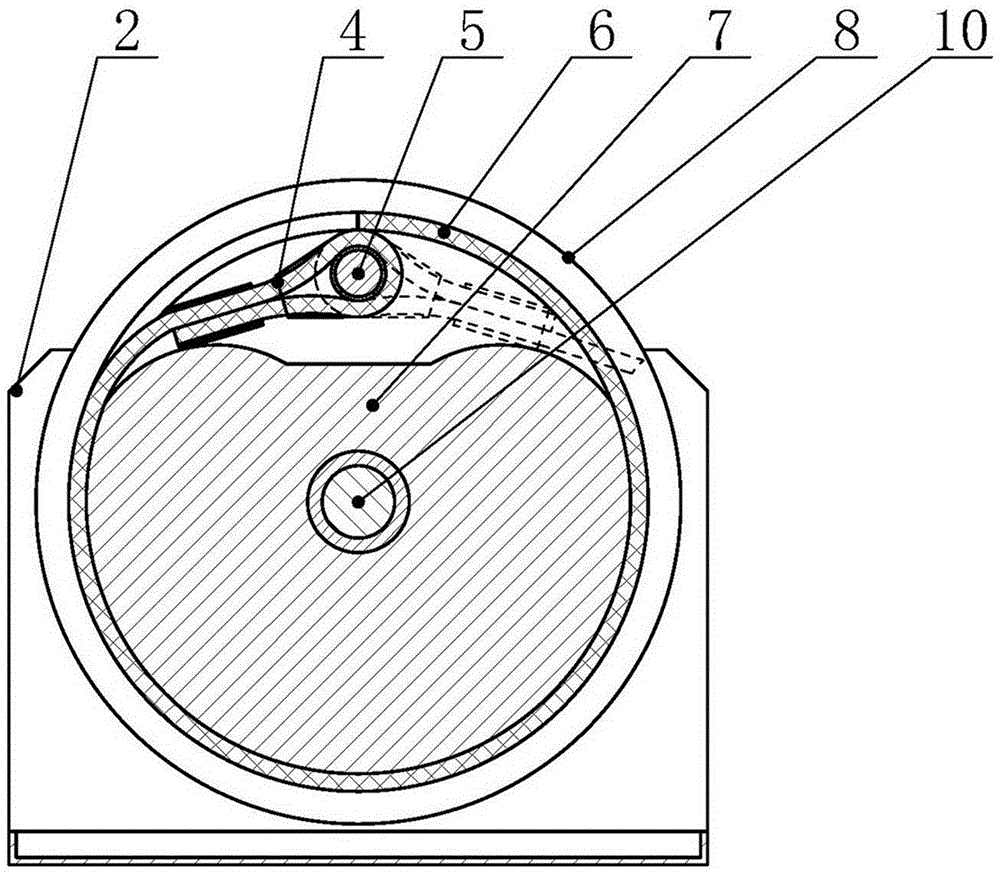

[0017] Such as figure 1 As shown, the present invention is mainly composed of a reel body assembly (8), a scroll spring assembly (9), a support seat (2) and a pretensioning device installed on the main shaft (10), and is characterized in that: the reel The body assembly (8) is installed in the middle of the support seat (2), the main shaft (10) passes through the reel body assembly (8) and the support seat (2), and the reel body assembly (8) is fixed on the main shaft (10) On the top, the main shaft (10) is installed on the support seat (2), the pre-tensioning device is installed on the left end of the main shaft (10), the scroll spring assembly (9) is installed on the right end of the main shaft, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com