Spring hydraulic buffer protection device and shuttle vehicle

A technology of hydraulic buffering and protection device, applied in the direction of spring, spring/shock absorber, shock absorber-spring combination, etc., can solve the problems of limited spring stroke and small elastic coefficient, and achieve the effect of buffering inertial impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

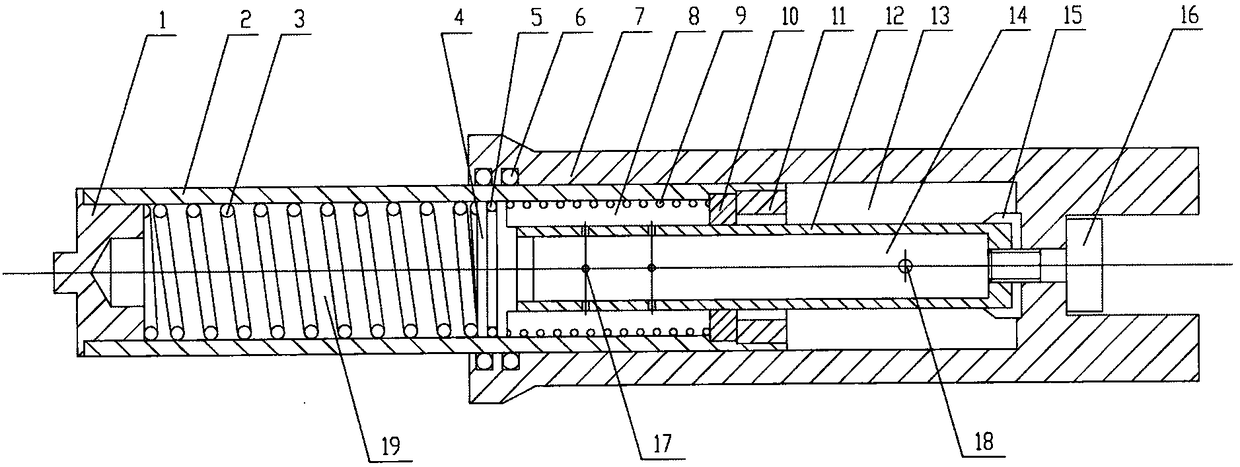

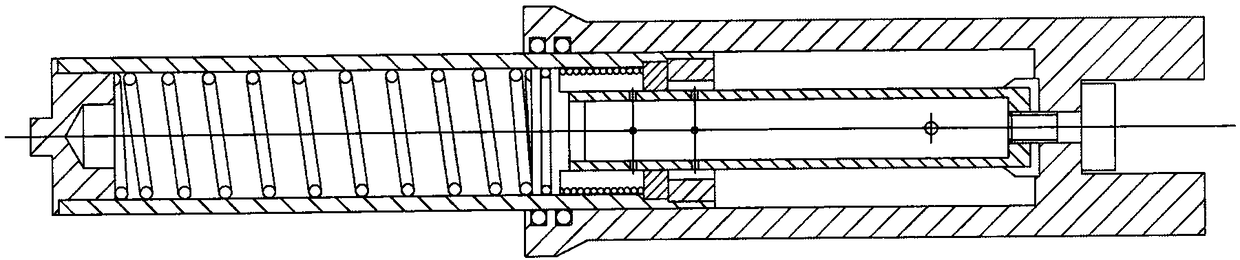

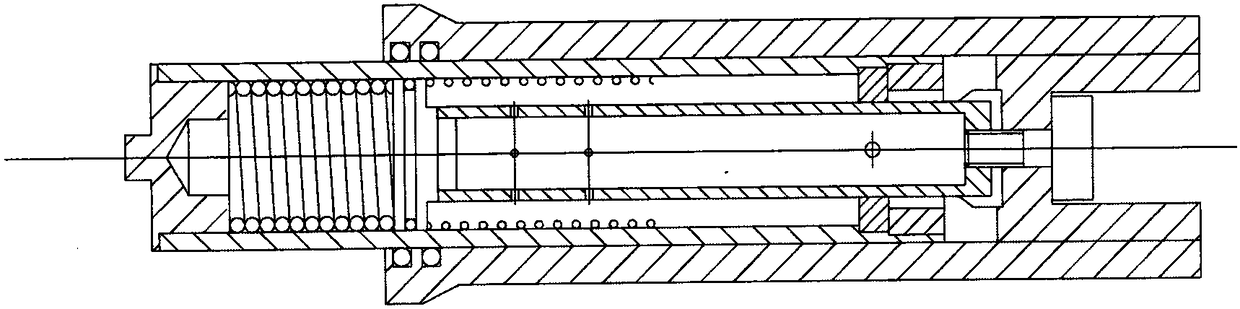

[0021] Such as Figure 1 to Figure 3 As shown, a spring hydraulic buffer protection device provided by the present invention is a built-in spring type, including an end cover 1, a piston barrel 2, a thrust spring 3, a piston 4, a small sealing ring 5, a large sealing ring 6, and a sleeve 7 , return spring 9, gasket 10, gasket stopper 11, damping cylinder 12, support seat 15, sealing bolt 16. The right end of piston cylinder 2 is put into sleeve 7 and fits with sleeve 7, and damping cylinder 12 is formed by The inner hole of the piston barrel 2 is loaded into the sleeve 7, and is fixed in the sleeve pipe 7 by the support seat 15 with the sealing bolt 16, and sealant is required for fixing. The piston 4 on the damping cylinder 12 is limited on the piston cylinder 2 to form a chamber one 8 . The wall of the damping cylinder 12 isolates the space on the right side of the piston 4 and divides it into cavity two 14 and cavity three 13 . Between the piston 4 and the piston barrel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com