Stage boom winch with mechanical anti-falling function

A mechanical hoist technology, applied to the hoisting device, spring mechanism, etc., can solve the problem of lack of stage boom hoisting machine, etc., and achieve the effect of short braking distance and sensitive action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

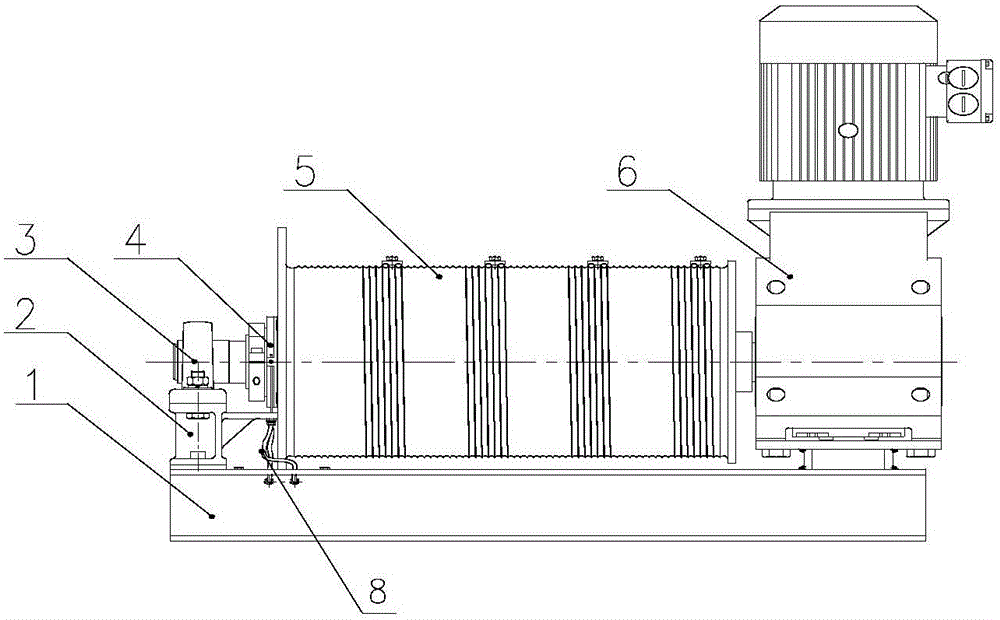

[0027] Such as figure 1 As shown, the specific implementation of the present invention includes a base mechanism 1, a support 2, a bearing with a seat 3, a reel mechanism 5 and a reduction motor 6, the bearing with a seat 3 is fixed on the support 2 and the support 2 is fixed on the base mechanism 1 , the reduction motor 6 is fixed on the base mechanism 1, the reel mechanism 5 shafts are installed between the belt seat bearing 3 and the reduction motor 6, and the reel mechanism 5 is driven to rotate by the reduction motor 6.

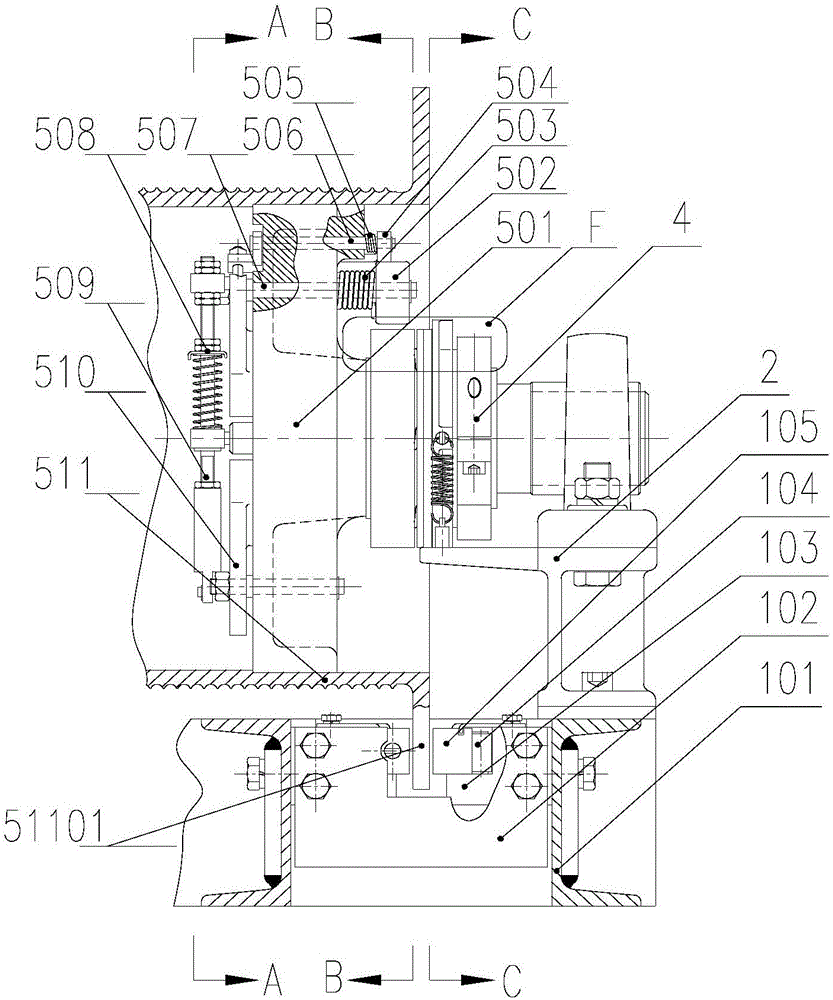

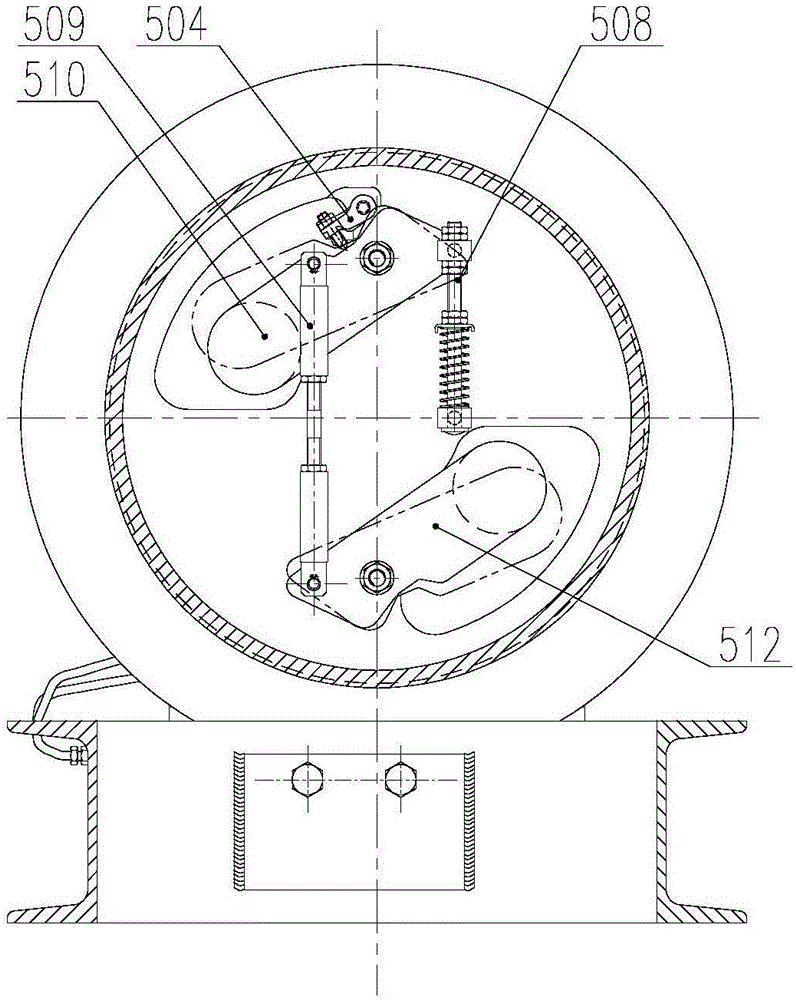

[0028] Such as figure 2 , image 3 As shown, the reel mechanism 5 includes a reel web shaft 501, an actuating adjustment rod 508, a balance connecting rod 509, two centrifugal hammers 510, 512, a reel cylinder body 511, and a motor mounted near the first centrifugal hammer 510. Positioning claw 504, pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com