A kind of mxene-polyaniline composite material and preparation method thereof

A composite material, polyaniline technology, which is applied in the field of preparation of MXene composite materials, can solve the problems of poor absorbing performance of MXene, and achieve the effects of enhancing the absorbing performance, improving the electrical performance and increasing the attenuation path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

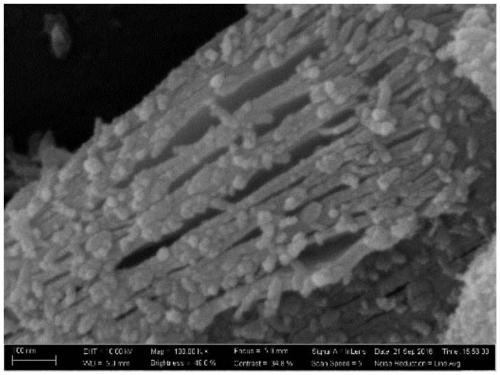

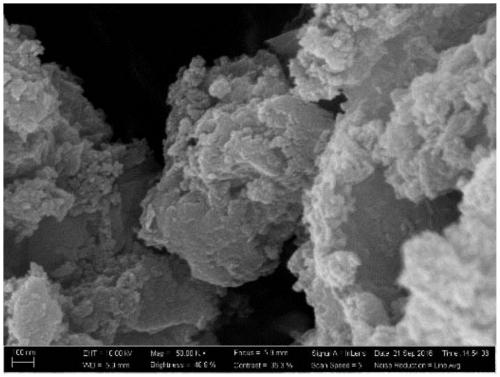

[0015] Embodiment 1: The MXene-polyaniline composite material of this embodiment is composed of a layered two-dimensional transition metal carbide and a polyaniline shell coated on the surface of the two-dimensional transition metal carbide, wherein the two-dimensional transition metal carbide The ratio of the mass of polyaniline or carbonitride to the mass of polyaniline is 1: (0.5-2.5).

specific Embodiment approach 2

[0016] Specific embodiment two: the preparation method of the MXene-polyaniline composite material described in specific embodiment one, carry out according to the following steps:

[0017] 1. Weigh two-dimensional transition metal carbide (MXene), aniline and ammonium persulfate [(NH 4 ) 2 S 2 o 8 ], wherein the ratio of the quality of two-dimensional transition metal carbide to the volume of aniline is 1g:(0.3~3)mL, the ratio of the quality of ammonium persulfate to the volume of aniline is (2.5~2.75)g:1ml;

[0018] 2. Add aniline to water, stir to obtain aniline / water dispersion, then use hydrochloric acid to adjust the pH value of the aniline / water dispersion to 1.5-2 to obtain aniline hydrochloride solution;

[0019] 3. Add the hydrochloride solution of aniline to the aqueous dispersion of the two-dimensional transition metal carbide, stir and mix at 0-5°C for 6-18 hours to obtain the MXene / aniline mixed solution;

[0020] 4. Dissolve ammonium persulfate in water, adj...

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the two-dimensional transition metal carbide described in step one is Ti 3 C 2 ; Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com