Sufficient-squeezing equipment of leather embryo for leather dyeing processing

A technology for skin embryos and leather, which is applied to the field of fully water-squeezing equipment for skin embryos used in leather dyeing and processing, can solve the problems of no centralized treatment of the extruded water, inconvenient replacement of parts, and splashing water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

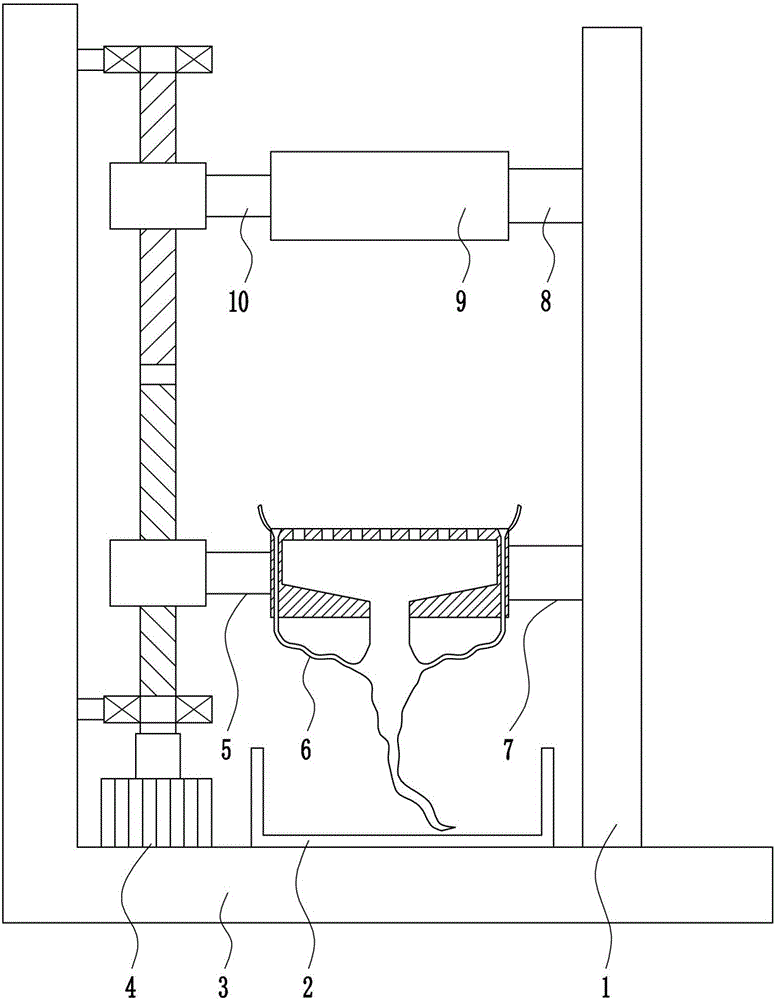

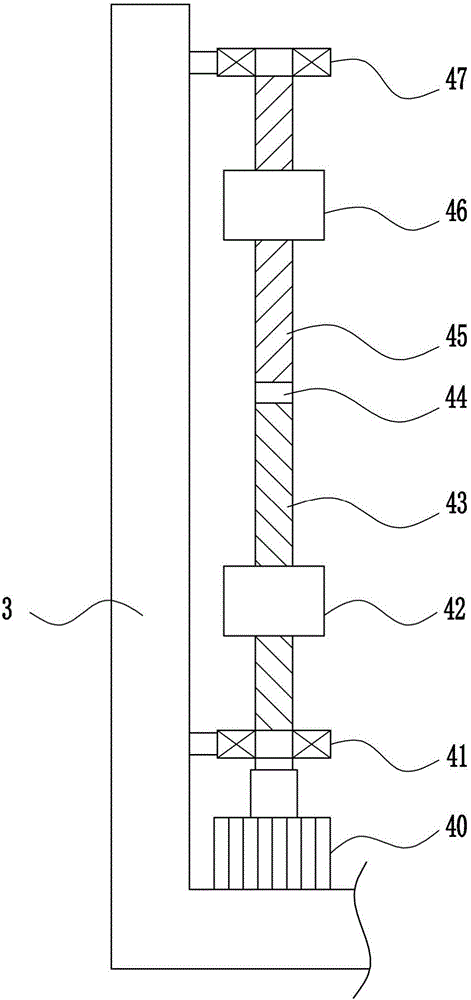

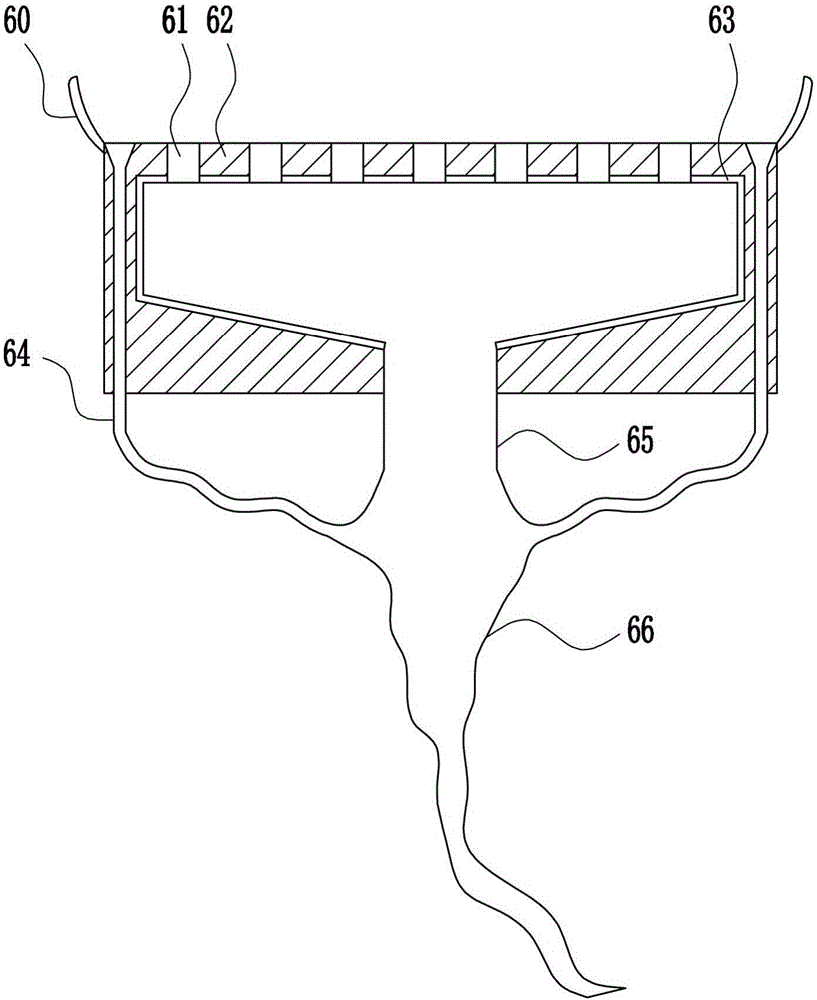

[0040] A kind of equipment for fully squeezing water of leather embryos for dyeing and processing of leather, such as Figure 1-8 As shown, it includes a vertical slide rail 1, a first water collection tank 2, an L-shaped bracket 3, a squeeze device 4, a first connecting rod 5, a flow guide mechanism 6, a lower slider 7, an upper slider 8, and an upper squeeze Water board 9 and second connecting rod 10, L-shaped bracket 3 inner bottom left side is provided with water squeezing device 4, and water squeezing device 4 left side is connected with L-shaped bracket 3 right sides, L-shaped bracket 3 inner bottom middle positions are provided with There is a first water collection tank 2, a vertical slide rail 1 is provided on the right side of the inner bottom of the L-shaped bracket 3, and a lower slider 7 and an upper slider 8 are arranged on the vertical slide rail 1, and the lower slider 7 and the upper slider 8 is located on the left side of the vertical slide rail 1, the lower ...

Embodiment 2

[0042] A kind of equipment for fully squeezing water of leather embryos for dyeing and processing of leather, such as Figure 1-8 As shown, it includes a vertical slide rail 1, a first water collection tank 2, an L-shaped bracket 3, a squeeze device 4, a first connecting rod 5, a flow guide mechanism 6, a lower slider 7, an upper slider 8, and an upper squeeze Water board 9 and second connecting rod 10, L-shaped bracket 3 inner bottom left side is provided with water squeezing device 4, and water squeezing device 4 left side is connected with L-shaped bracket 3 right sides, L-shaped bracket 3 inner bottom middle positions are provided with There is a first water collection tank 2, a vertical slide rail 1 is provided on the right side of the inner bottom of the L-shaped bracket 3, and a lower slider 7 and an upper slider 8 are arranged on the vertical slide rail 1, and the lower slider 7 and the upper slider 8 is located on the left side of the vertical slide rail 1, the lower ...

Embodiment 3

[0045] A kind of equipment for fully squeezing water of leather embryos for dyeing and processing of leather, such as Figure 1-8 As shown, it includes a vertical slide rail 1, a first water collection tank 2, an L-shaped bracket 3, a squeeze device 4, a first connecting rod 5, a flow guide mechanism 6, a lower slider 7, an upper slider 8, and an upper squeeze Water board 9 and second connecting rod 10, L-shaped bracket 3 inner bottom left side is provided with water squeezing device 4, and water squeezing device 4 left side is connected with L-shaped bracket 3 right sides, L-shaped bracket 3 inner bottom middle positions are provided with There is a first water collection tank 2, a vertical slide rail 1 is provided on the right side of the inner bottom of the L-shaped bracket 3, and a lower slider 7 and an upper slider 8 are arranged on the vertical slide rail 1, and the lower slider 7 and the upper slider 8 is located on the left side of the vertical slide rail 1, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com