A method of controlling nitrogen content in high nitrogen steel

A technology of nitrogen content and high nitrogen steel is applied in the field of controlling nitrogen content in high nitrogen steel, which can solve the problems of inability to achieve precise nitrogen control, unstable nitrogen absorption rate of nitrogen alloys, and the cost of large alloys, so as to enhance the market. Competitiveness, improving molten steel cleanliness, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

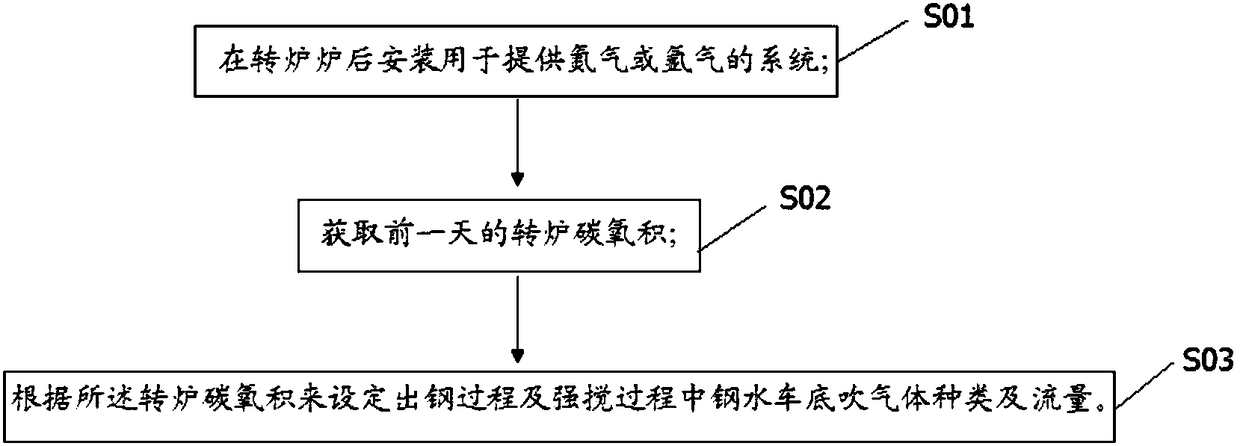

[0043] Embodiment 1 of the present invention controls the method for nitrogen content in high nitrogen steel, described method comprises the steps:

[0044] S101: Install a system for supplying nitrogen or argon after the converter;

[0045] S102: Obtain the carbon and oxygen product of the converter of the previous day;

[0046] S103: According to the carbon and oxygen product of the converter, set the type and flow rate of the bottom blowing gas of the molten steel car during the tapping process and the strong stirring process.

[0047] In the step S101, in the embodiment of the present invention, a system for supplying nitrogen or argon is installed on the molten steel car behind the converter, and the system includes a gas pipeline, a cut-off valve and a flow meter. The system is connected to the primary program of the control system to realize automatic and manual control.

[0048] In the step S103, when the carbon-oxygen product of the converter ≥ 0.0030 the previous d...

Embodiment 2

[0052] Embodiment 2 of the present invention controls the method for nitrogen content in high nitrogen steel, described method comprises the following steps:

[0053] S201: Install a system for supplying nitrogen or argon after the converter furnace;

[0054] S202: Obtain the carbon and oxygen product of the converter of the previous day;

[0055] S203: According to the carbon and oxygen product of the converter, set the type and flow rate of the bottom blowing gas of the molten steel car during the tapping process and the strong stirring process;

[0056] S204: Nitrogen is used as the circulating gas in the RH refining process, and the balance vacuum degree is set according to the target nitrogen content of the finished steel.

[0057] In the step S201, in the embodiment of the present invention, a system for supplying nitrogen or argon is installed on the molten steel car behind the converter, and the system includes a gas pipeline, a cut-off valve and a flow meter. The sy...

Embodiment 3

[0065] Embodiment 3 of the present invention controls the method for nitrogen content in high nitrogen steel, described method comprises the following steps:

[0066] S301: Install a system for supplying nitrogen or argon after the converter;

[0067] S302: Obtain the carbon and oxygen product of the converter of the previous day;

[0068] S303: According to the carbon and oxygen product of the converter, set the type and flow rate of the bottom blowing gas of the molten steel car during the tapping process and the strong stirring process;

[0069] S304: Nitrogen is used as the circulating gas in the RH refining process, and the balance vacuum degree is set according to the target nitrogen content of the finished steel;

[0070] S305: In the RH refining process, take a process sample of molten steel to test the nitrogen content, and select the final circulating gas parameters according to the difference between the nitrogen content value obtained from the test and the final t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com