An automatic brick press device

A brick press, automatic technology, applied in the field of raw material processing equipment, can solve the problems of sensor command failure, palletizing robot misoperation, affecting production, etc., to achieve the effect of saving manpower, compact pressing and palletizing process, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

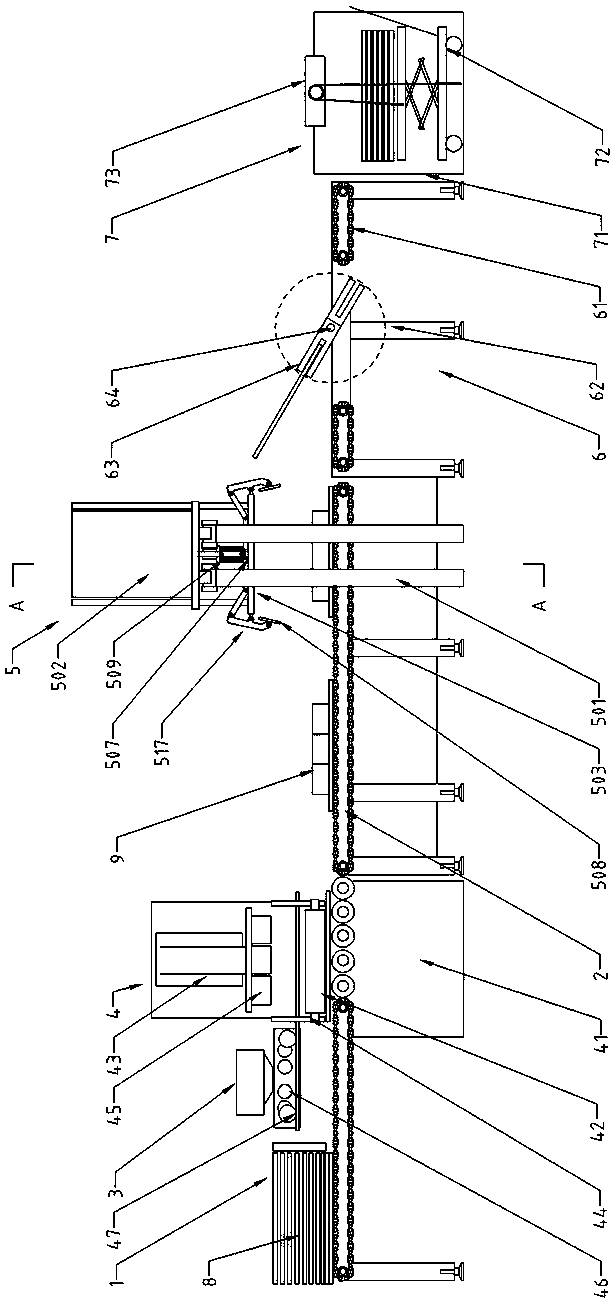

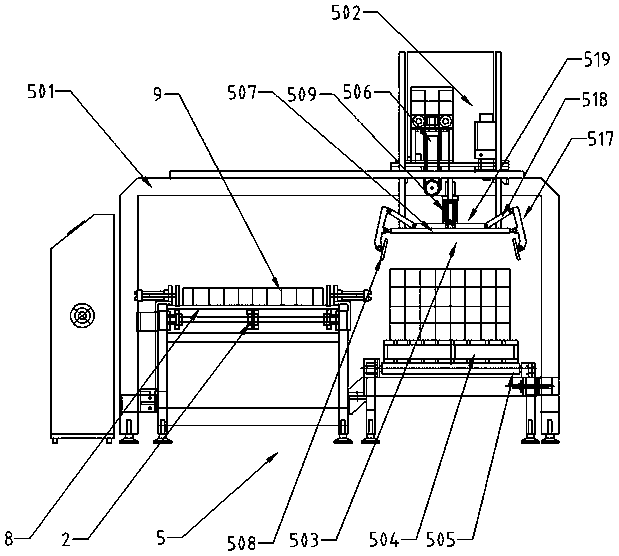

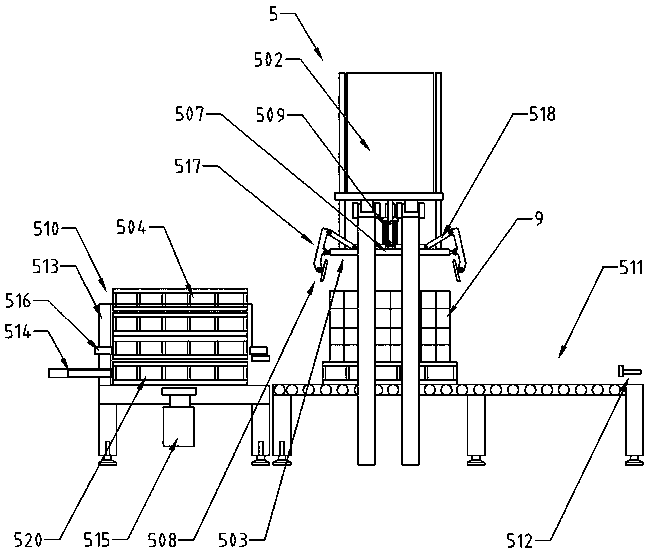

[0019] attached Figure 1-3 Indicates an automatic brick press device, including a hydraulic pump station, an automatic pallet conveying frame (1), a main conveying line (2) composed of multi-section chain roller conveying mechanisms, a feeding hopper (3), and a brick press machine (4), automatic palletizer (5), plate turning machine (6), pallet collecting mechanism (7) and electrical control device; the automatic pallet conveying frame (1) is three Enclosure with semi-enclosed side and empty bottom, stacked pallets (8) inside the enclosure, and the starting end of the main conveying line (2) below the bottom; the front plate straddles the main conveying line (2), and the The height of the thickness of 1-1.5 pallets should be maintained between the top and bottom of the line (2);

[0020]The brick press (4) includes a press frame (41), a cloth frame (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com