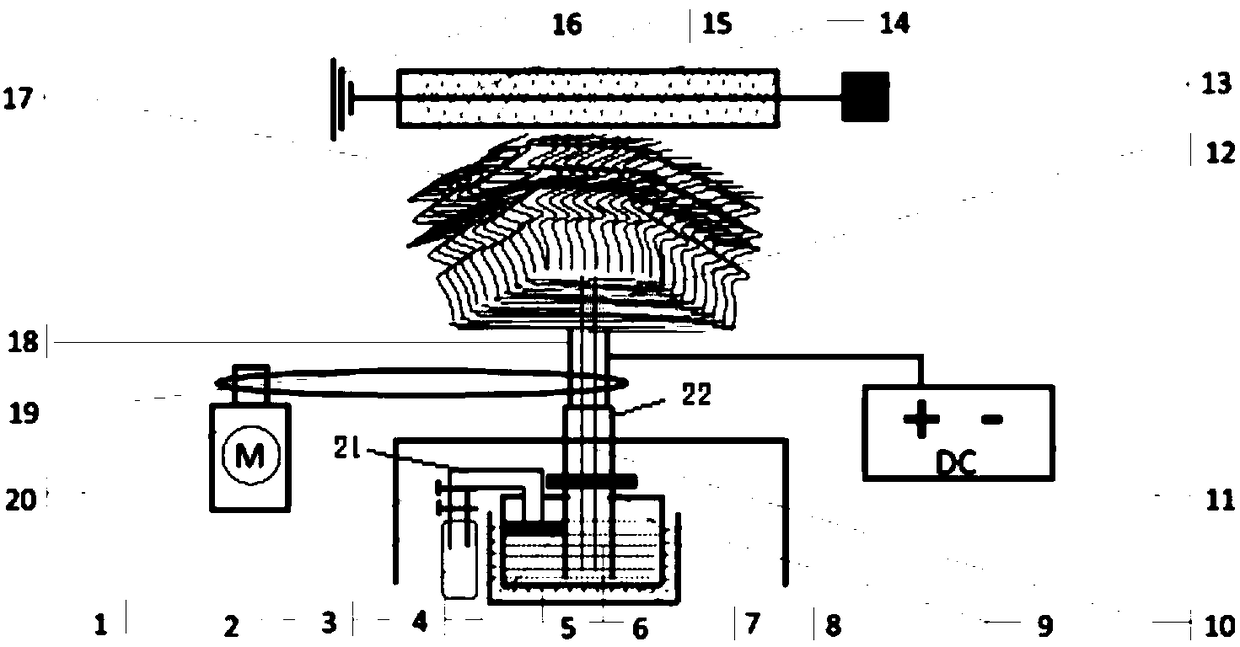

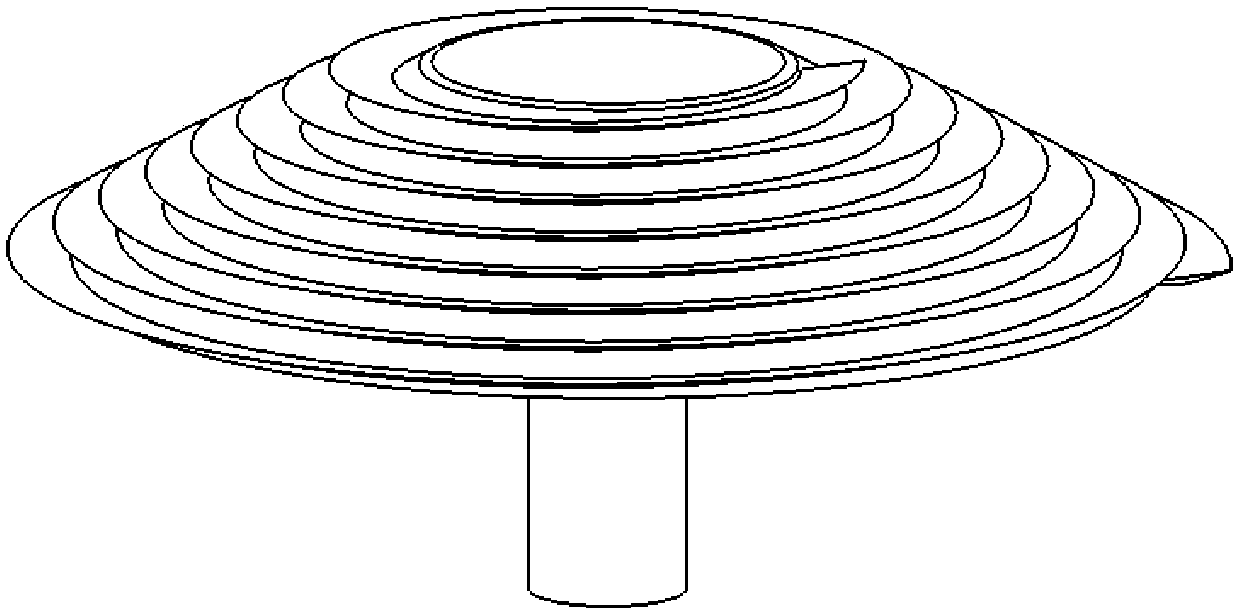

A spiral groove-shaped electrospinning device and method of using the same

A spiral groove and electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the fluctuation of solvent volatilization concentration of the solution to be spun, non-oriented structure of nanofiber products, and low output of nanofibers and other issues, to achieve the effect of automatic supply and control, strengthened control, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 12%. The configured PAN / DMF polymer solution is injected into the spinning solution storage bottle 7, and the spinning solution storage bottle 7 and the spiral groove nozzle 12 are connected with the catheter 10. Add silicone oil 5 into the oil bath 9, and heat it to the set temperature of 30° C. with a hot stage. Open the middle switch 8 of the catheter tube 10, open the main valve 2 of the gas cylinder 3, adjust the pressure reducing valve 1 to push the piston 4 so that the polymer solution 6 slowly flows into the spiral groove nozzle 12 through the catheter tube 10, so that the polymer solution The solution 6 is present in a quantity in the helical groove shower head 12 . Connect the metal drum 14 to the ground wire 16, turn on the motor 13 connected to the metal drum 14, ensure th...

Embodiment 2

[0051] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 10%. The configured PAN / DMF polymer solution is injected into the spinning solution storage bottle 7, and the spinning solution storage bottle 7 and the spiral groove nozzle 12 are connected with the catheter 10. Add silicone oil 5 into the oil bath 9, and heat it to the set temperature of 40° C. with a hot stage. Open the middle switch 8 of the catheter tube 10, open the main valve 2 of the gas cylinder 3, adjust the pressure reducing valve 1 to push the piston 4 so that the polymer solution 6 slowly flows into the spiral groove nozzle 12 through the catheter tube 10, so that the polymer solution The solution 6 is present in a quantity in the helical groove shower head 12 . Connect the metal drum 14 to the ground wire 16, turn on the motor 13 connected to the metal drum 14, ensure th...

Embodiment 3

[0053] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N-N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 12%. The configured PAN / DMF polymer solution is injected into the spinning solution storage bottle 7, and the spinning solution storage bottle 7 and the spiral groove nozzle 12 are connected with the catheter 10. Add silicone oil 5 into the oil bath 9, and heat it to the set temperature of 30° C. with a hot stage. Open the middle switch 8 of the catheter tube 10, open the main valve 2 of the gas cylinder 3, adjust the pressure reducing valve 1 to push the piston 4 so that the polymer solution 6 slowly flows into the spiral groove nozzle 12 through the catheter tube 10, so that the polymer solution The solution 6 is present in a quantity in the helical groove shower head 12 . Connect the metal drum 14 to the ground wire 16, turn on the motor 13 connected to the metal drum 14, ensure th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com