A yarn wrapping machine

A covering machine and yarn technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of affecting work efficiency, inconvenient loading and unloading of yarn bobbins, complex structure, etc., so as to improve the degree of automation, reduce the cost of use, and take out conveniently and quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

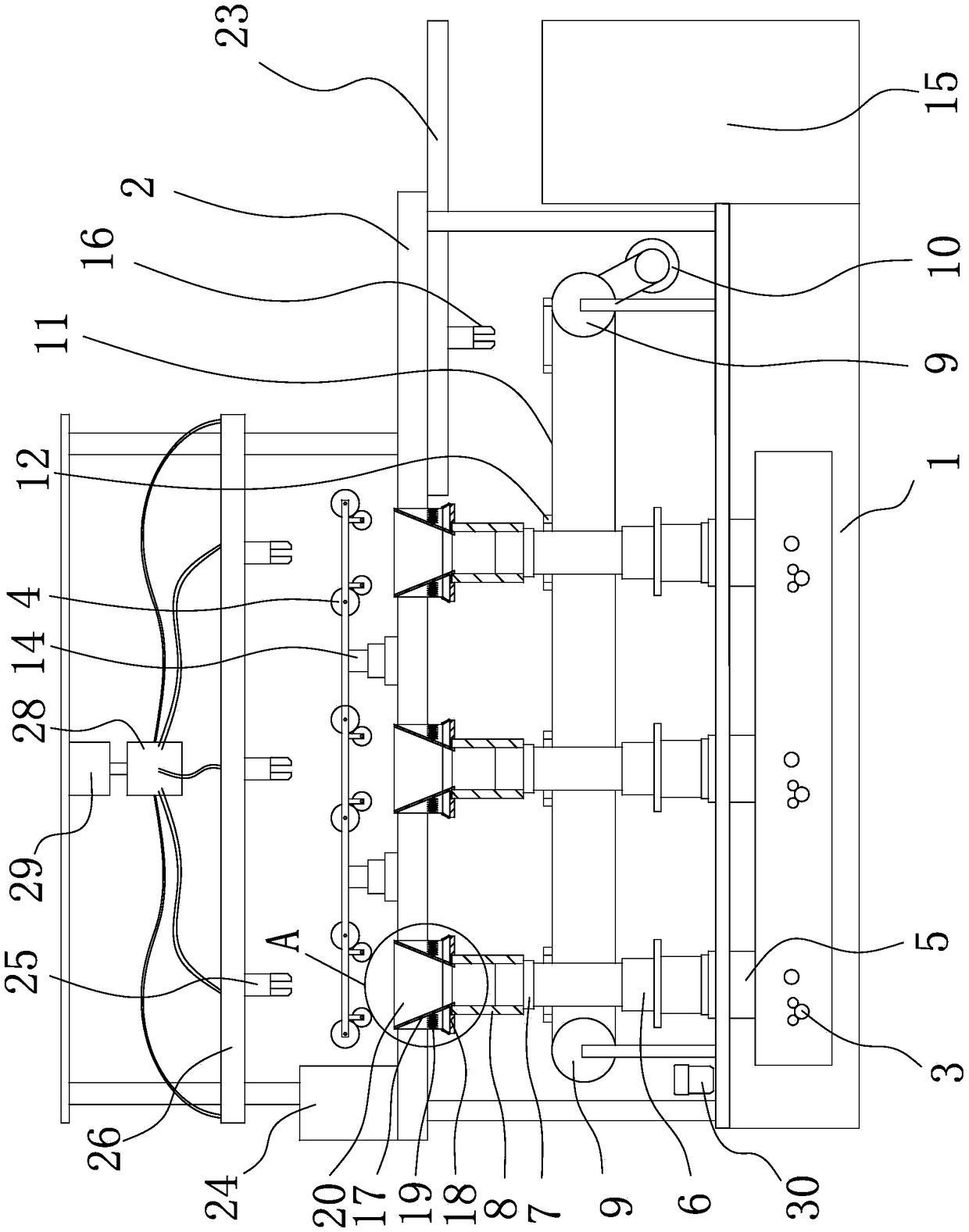

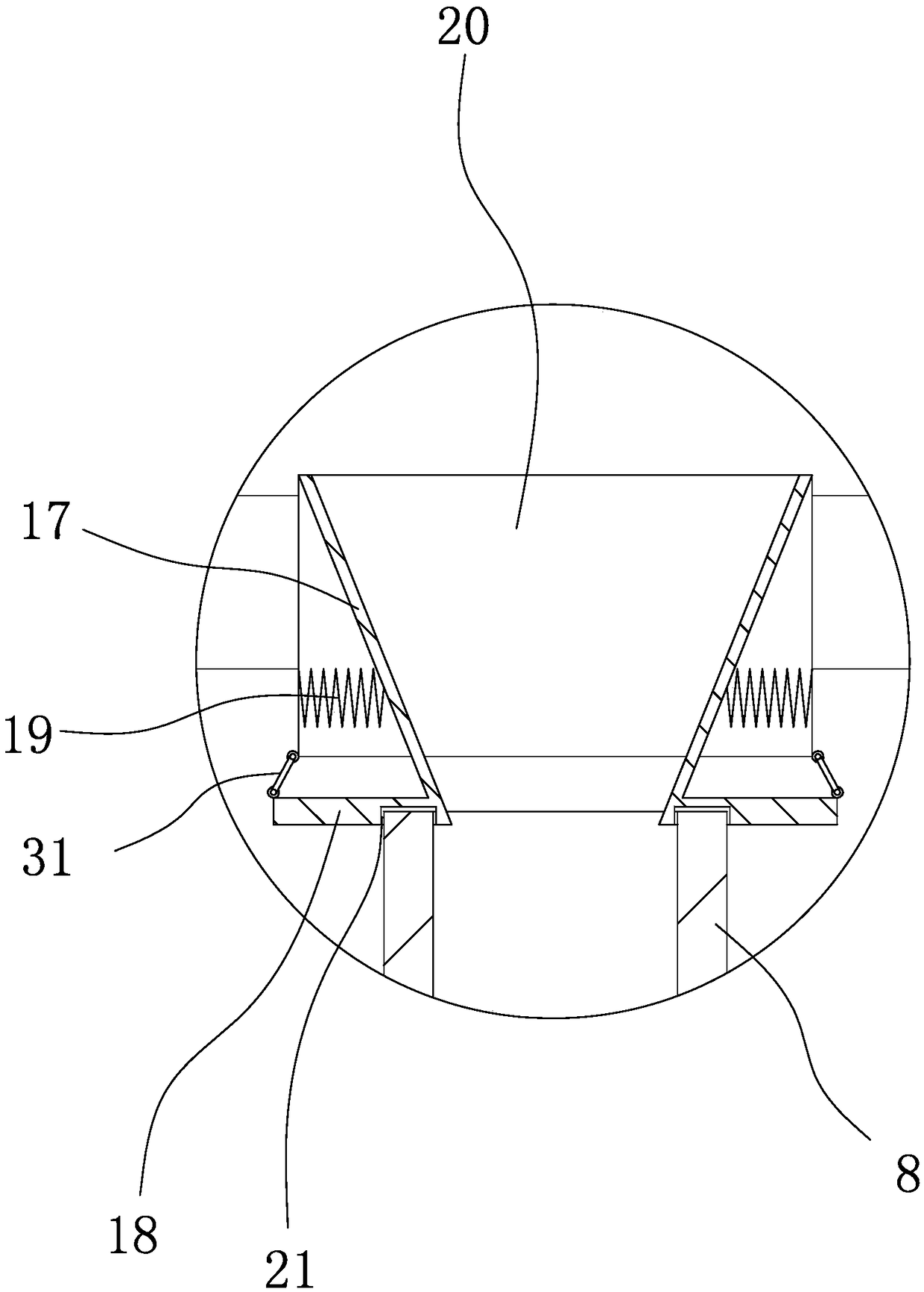

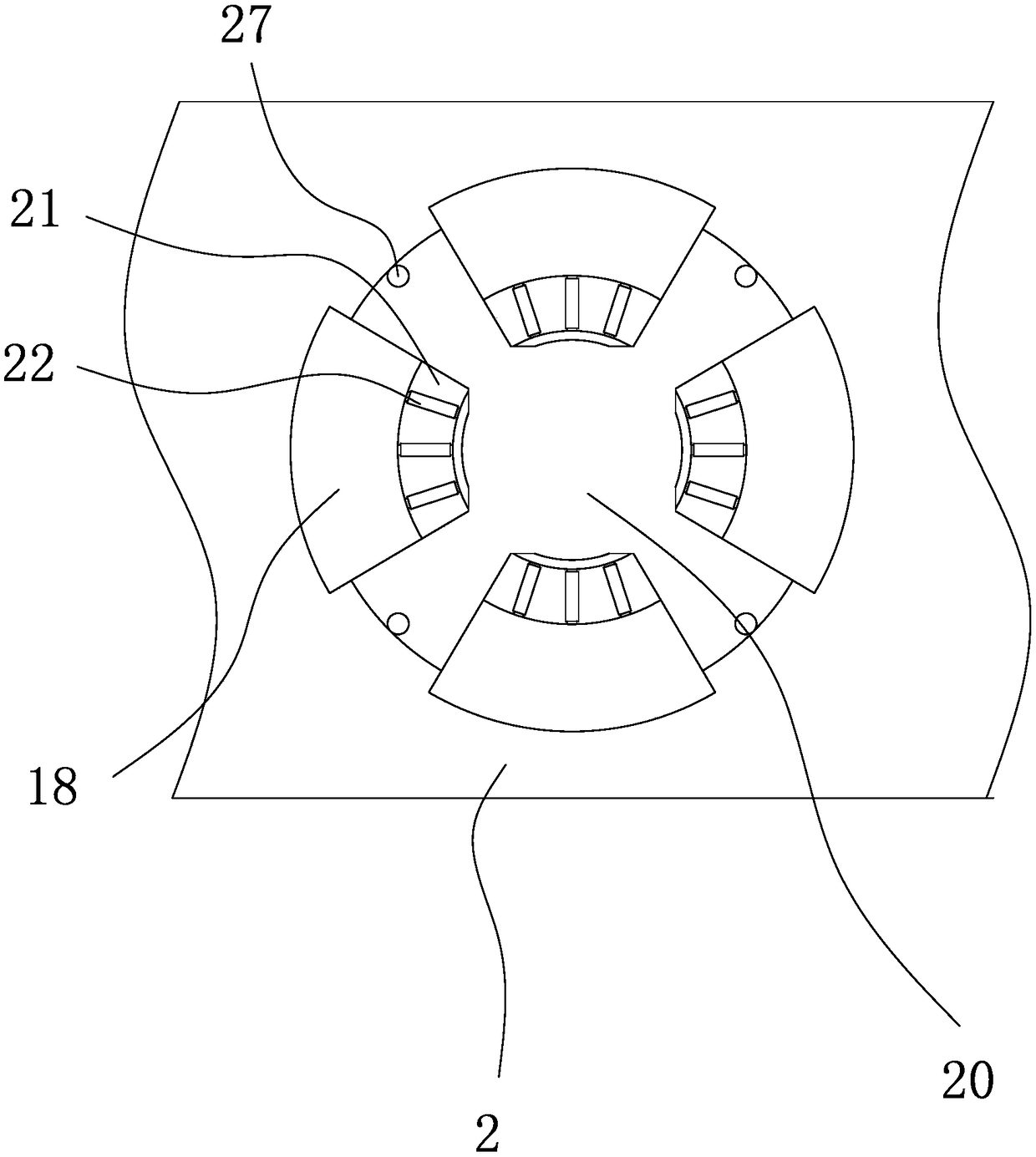

[0026] refer to figure 1 , the present embodiment is a kind of yarn wrapping machine, comprises workbench 1 and support 2, support 2 is positioned at the top of workbench 1, workbench 1 is provided with feeding mechanism 3, and support 2 is provided with traction mechanism 4 and with The lifting seat 14 that drives the traction mechanism 4 up and down. An electric control device for controlling the automatic operation of each component of the yarn covering machine is arranged in the workbench 1 . Workbench 1 is provided with several rotating shafts 5 driven by the second driving motor 30 to realize synchronous rotation. Fixedly connected with the spindle 7, the center line of the spindle 7 and the center line of the electric t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com