Formwork supporting structure for reserved hole roof cover construction

A technology of formwork support and reserved holes, which is applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components. The effect of supporting capacity, reducing complexity and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

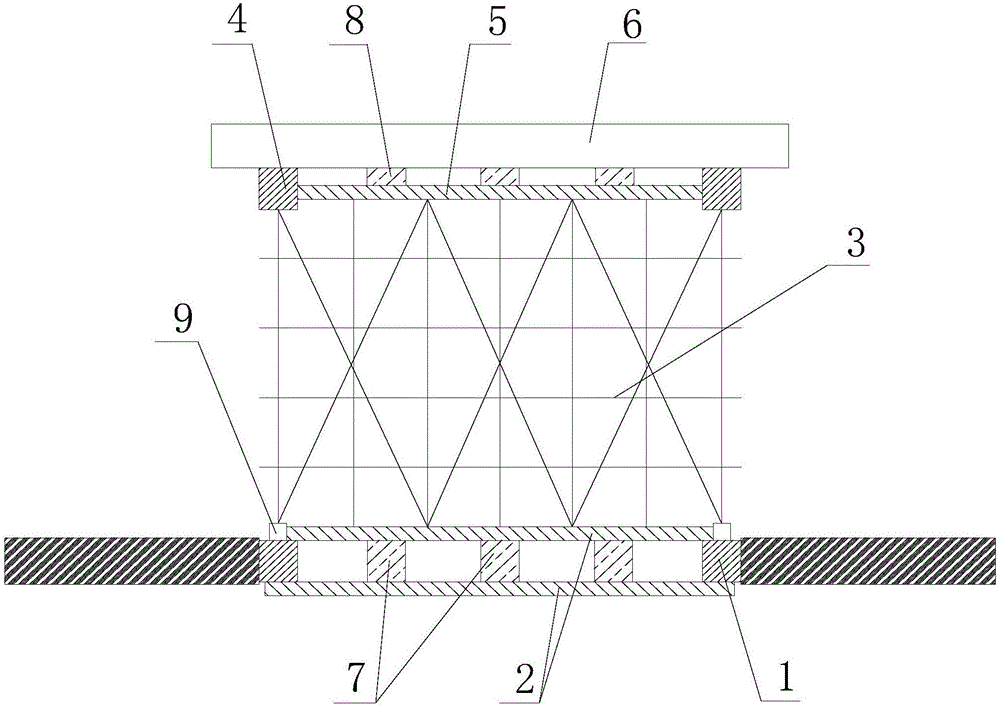

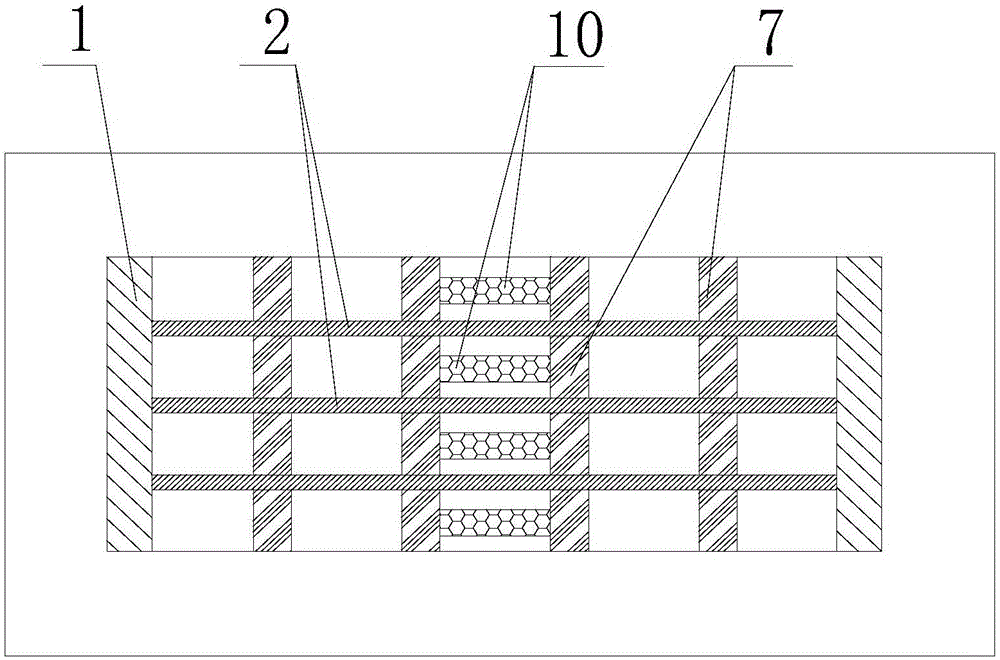

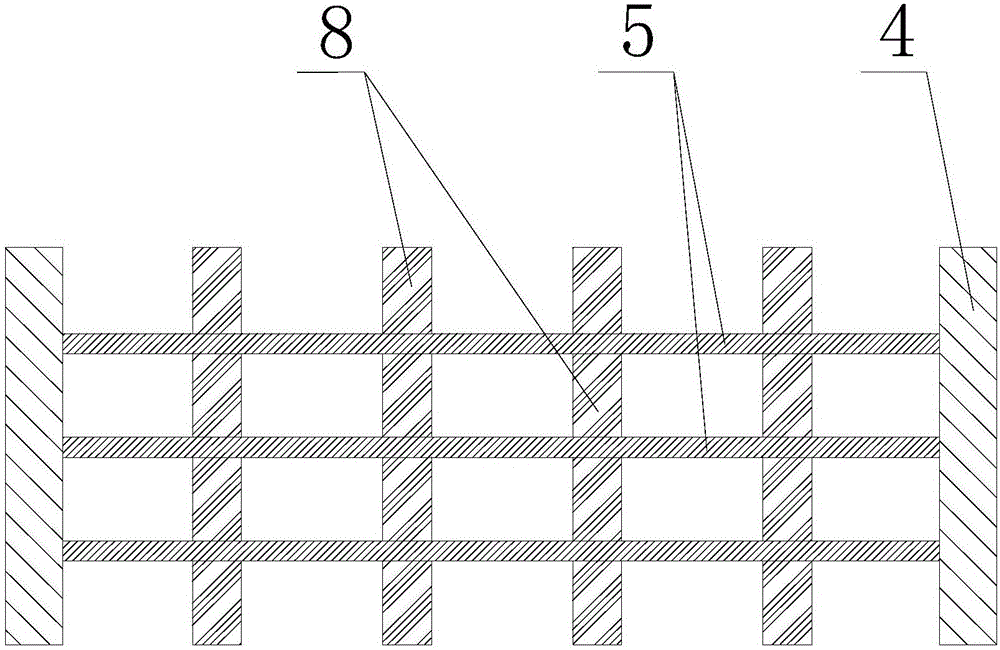

[0028] Such as Figure 1 to Figure 3 The shown formwork support structure for the roof construction of reserved holes includes several layers of reserved holes, and is characterized in that fixed steel beams 1 are arranged at the opposite sides of the opening of the topmost reserved hole. A number of evenly distributed secondary beams 2 are fixed between the steel beams 1. The two ends of the secondary beams 2 are respectively fixed on the steel beams 1 on both sides. Supporting scaffolds 3 are erected on the steel beams 1 on both sides. The bases of the scaffold 3 are respectively set on the profiled steel beams 1 on both sides; the top of the supporting scaffold 3 is provided with two under-slab support beams 4, the two under-slab support beams 4 are directly opposite to the two profiled steel beams 1, and the two under the slab A number of evenly distributed slab next beams 5 are fixed between the support beams 4, and the two ends of the slab next beam 5 are respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com