Raising fence

A technology of guardrail and bottom rail, applied in the field of aquaculture, can solve the problems of single fixing of metal railings, affecting the growth of animals, prone to tilt, etc., to achieve the effect of ensuring normal growth, maintaining stability, and avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

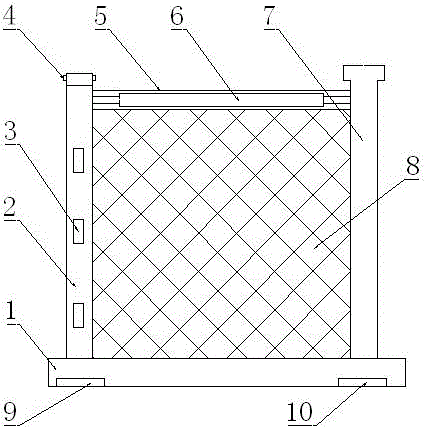

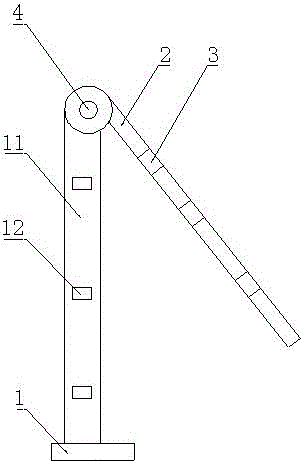

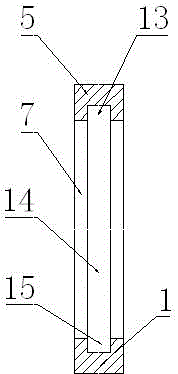

[0021] Such as Figure 1-4 Shown, a kind of breeding guardrail, it comprises bottom fence 1, described bottom fence 1 two ends are respectively provided with fixed seat A9 and fixed seat B10, and described fixed seat A9 and fixed seat B10 are provided with evenly distributed through A hole 16, a groove C15 is opened inside the top of the bottom column 1, a vertical column B11 is connected to the top of the left end of the bottom column 1, a vertical column A7 is connected to the top of the right end of the bottom column 1, and the vertical column B11 is provided with evenly distributed locks 12, the top of the vertical bar B11 is connected with a splint 2, and the splint 2 is provided with evenly distributed lock holes 3, and the left side of the vertical bar A7 is along the vertical direction There is a groove B14, a horizontal bar 5 is connected between the vertical column A7 and the vertical column B11, a light tube 6 is installed in the horizontal column 5, and a groove A1...

Embodiment 2

[0024] Such as Figure 1-4 Shown, a kind of breeding guardrail, it comprises bottom fence 1, described bottom fence 1 two ends are respectively provided with fixed seat A9 and fixed seat B10, and described fixed seat A9 and fixed seat B10 are provided with evenly distributed through A hole 16, a groove C15 is opened inside the top of the bottom column 1, a vertical column B11 is connected to the top of the left end of the bottom column 1, a vertical column A7 is connected to the top of the right end of the bottom column 1, and the vertical column B11 is provided with evenly distributed locks 12, the top of the vertical bar B11 is connected with a splint 2, and the splint 2 is provided with evenly distributed lock holes 3, and the left side of the vertical bar A7 is along the vertical direction There is a groove B14, a horizontal bar 5 is connected between the vertical column A7 and the vertical column B11, a light tube 6 is installed in the horizontal column 5, and a groove A1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com