A diameter expandable heel tube using screw heads

A screw head and external thread technology, which is applied to the field of using screw heads for follow-up pipes, can solve the problems that the casing cannot be pressed down to a predetermined depth, the pipe-following drill bit and the casing are worn, the hole wall collapses, etc., so as to improve the pipe-following efficiency, The effect of reducing wear and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

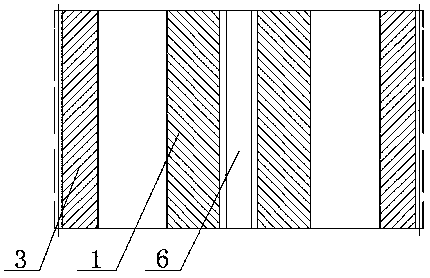

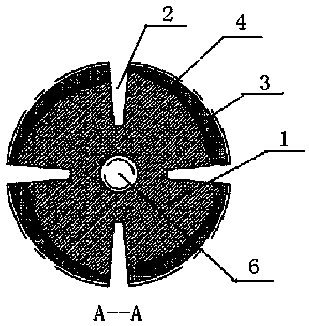

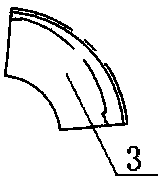

[0021] Embodiment of the present invention: a kind of telescopic heel tube uses screw head, as attached Figure 1-4 As shown, it includes a curved screw head 1, which is divided into several unit blocks through several wedge-shaped grooves 2, and an external thread structure 3 is arranged on the outside of the curved screw head 1 of each unit block. A ball 4 is arranged between the thread structure 3 and the curved screw head 1; the outer surface of each curved screw head 1 and the inner surface of the external thread structure 3 are the same shrinking curved surface, and the outer surface of the external thread structure 3 is a circle The outer surface of each curved screw head 1 and the inner surface of the external thread structure 3 are provided with a groove 5, and a cylindrical ball 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com