Unhairing machine for fabric printing and dyeing

A wool machine and fabric technology, applied in the field of printing and dyeing, can solve problems such as endangering personal safety of personnel, affecting processing quality, and fabric surface damage, and achieving the effect of improving friction effect, reducing self-consumption, and promoting friction strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

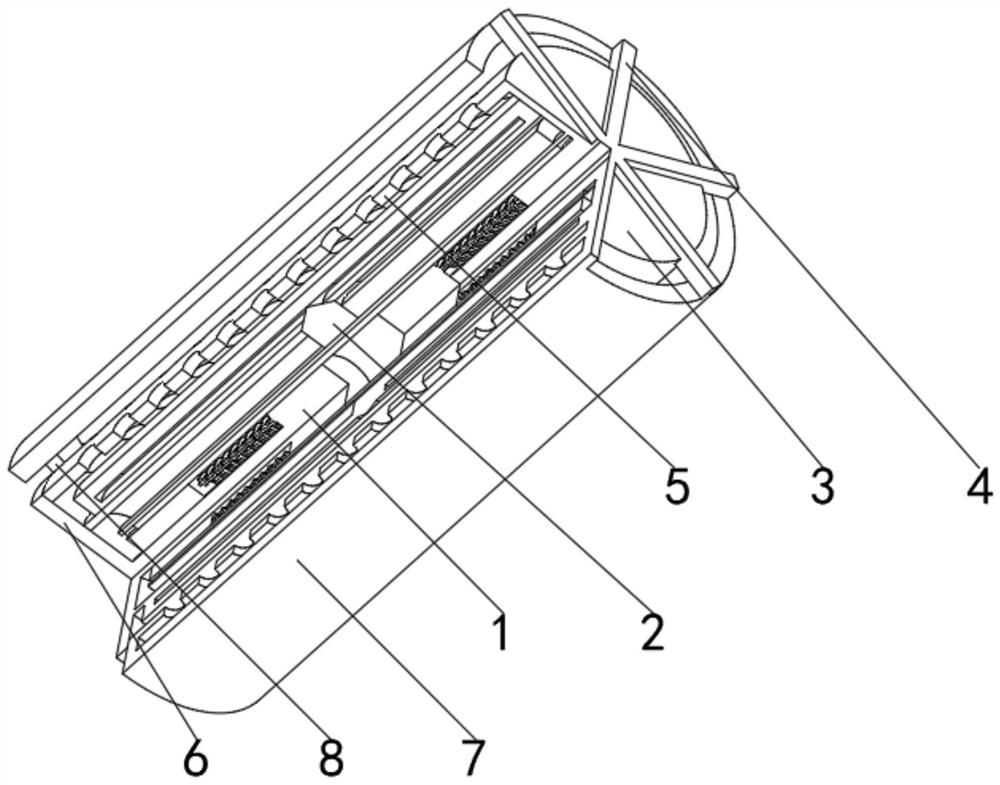

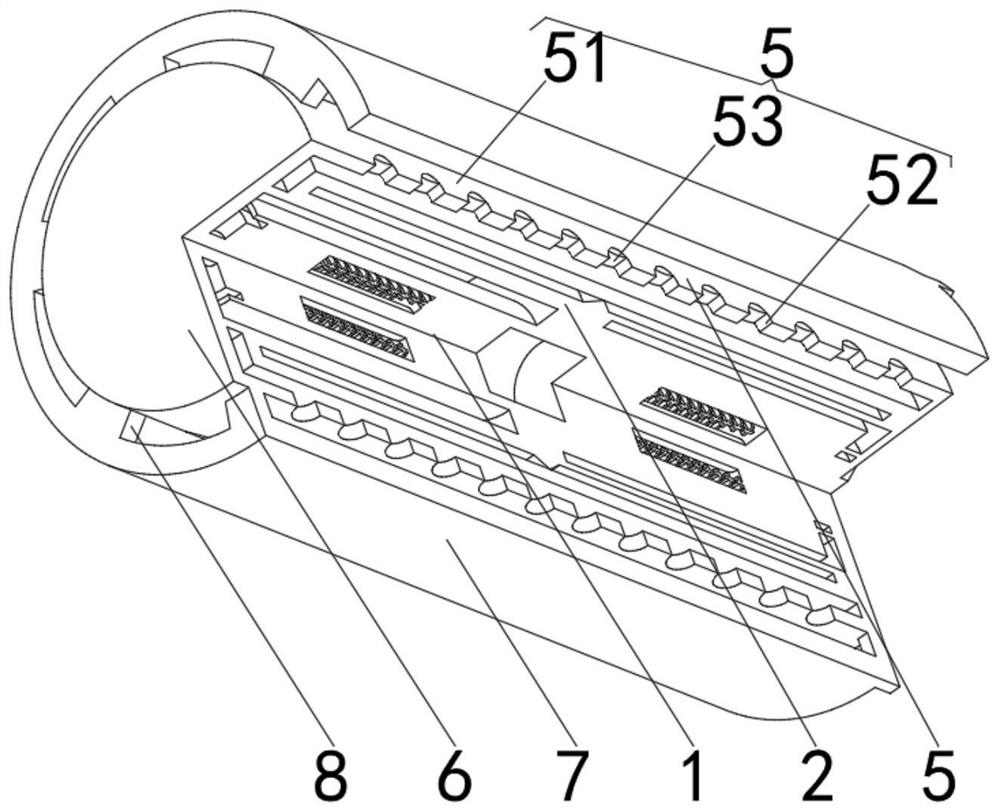

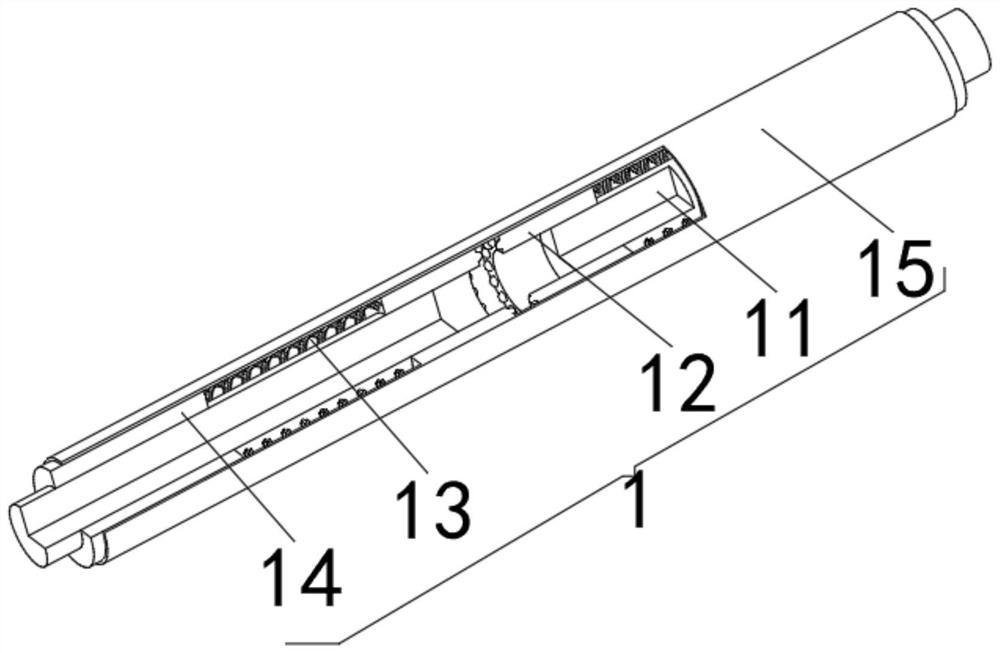

[0036] see Figure 1-6 , the present invention provides a technical solution: a fabric printing and dyeing hair removal machine, including a central mechanism 1, the outer surface of the central mechanism 1 is fixedly connected with an air guiding mechanism 2, and the top of the central mechanism 1 is movably connected with an installation panel 3, and the installation panel 3 is away from the One side of the central mechanism 1 is rotatably connected with a reinforced fixing frame 4, the bottom of the installation panel 3 is located at the side of the air guiding mechanism 2 far away from the central mechanism 1 and is movably connected with a guide tube 5, and the bottom of the central mechanism 1 is fixedly connected with a positioning plate 6, strengthening The bottom of the fixed frame 4 is located on the side of the guide cylinder 5 away from the air guide mechanism 2 and is fixedly connected with a burning roller 7. The bottom of the air guide mechanism 2 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com