Quick heat exchange minitype thermal shock testing device

A technology of cold and heat shock and test device, which is applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as uneven heating and cooling, and achieve the effect of accelerating heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

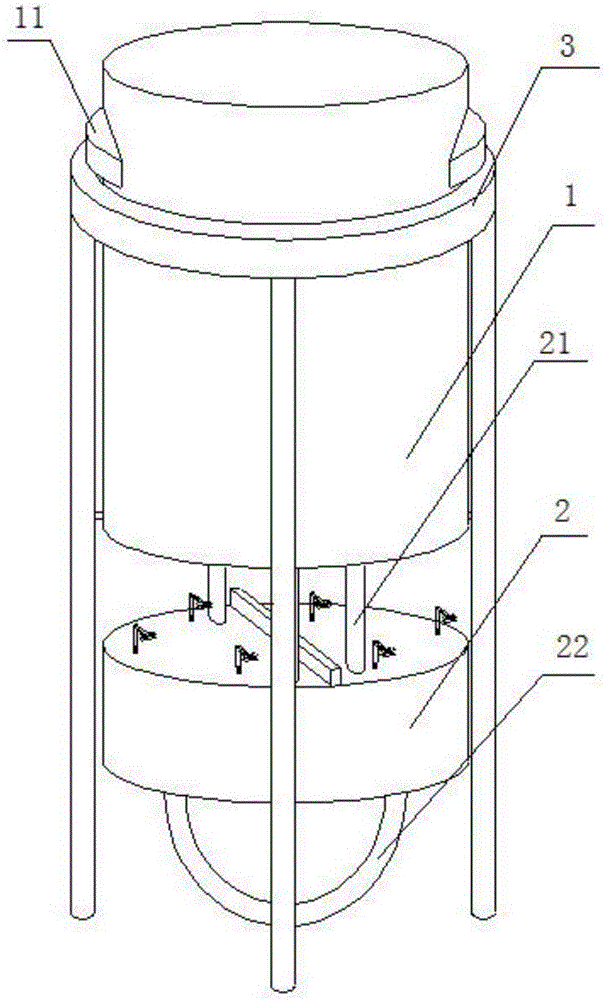

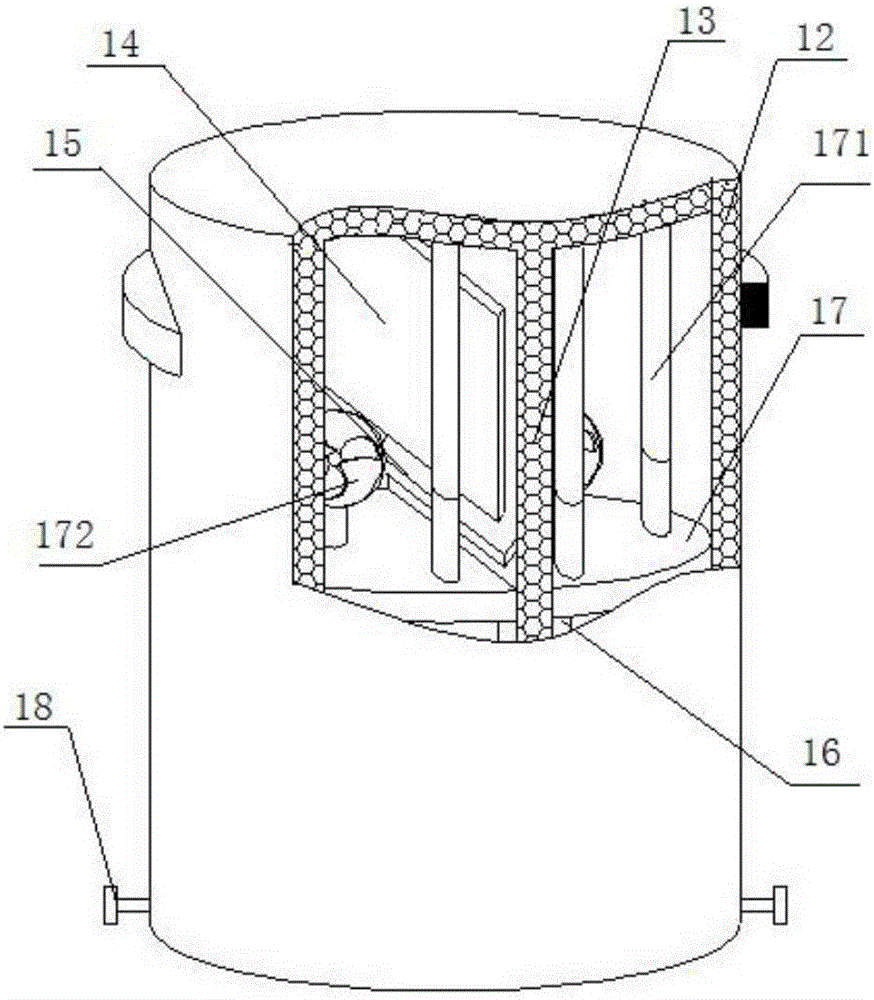

[0029] Such as figure 1 , figure 2 , Figure 4 , Figure 7 As shown, a miniature cold and thermal shock test device with rapid heat exchange includes a test body 1 and a test sample mounting base 2 that are socketed up and down. The test body 1 is covered with a bracket 3, and the test body 1 includes a thermal insulation shell 12 The thermal insulation shell 12 is cylindrical with an open lower end, and a thermal insulation partition 13 is arranged inside the thermal insulation casing 12. The thermal insulation partition 13 and the test sample installation base 2 separate the thermal insulation casing 12 into a cold test room and a cold test chamber independently arranged on the left and right sides. The thermal test room, the cold test room and the hot test room are respectively equipped with a refrigeration device and a heating device; the inner wall of the heat preservation shell 12 is provided with a limit block 15 and a sealing ring plate 16, and the inner wall of the...

Embodiment 2

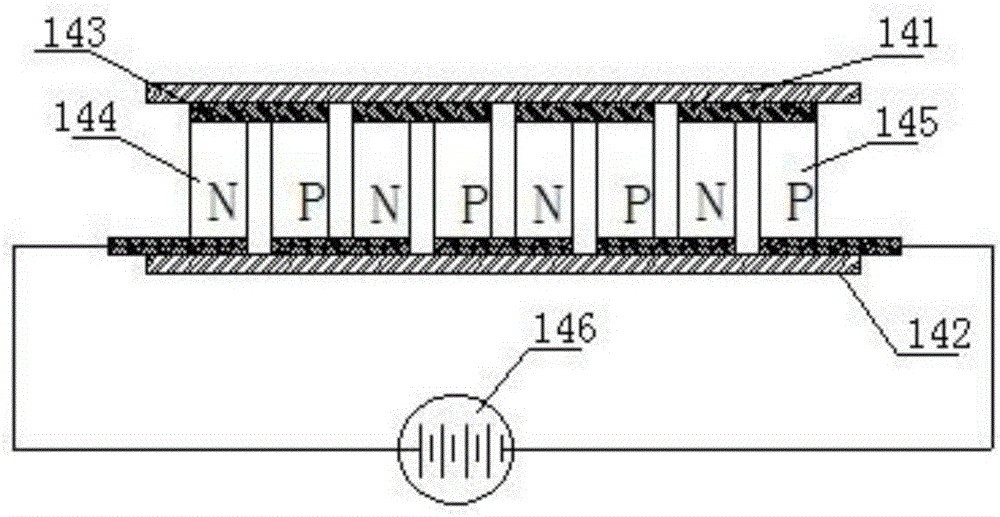

[0037] Such as image 3 As shown, further optimization is carried out on the basis of a rapid heat transfer miniature thermal shock test device described in Example 1. The upper half of the heat insulation partition 13 is inlaid with a semiconductor refrigeration device 14, and the semiconductor refrigeration The device 14 is located above the limit block 15. The semiconductor refrigeration device 14 is composed of a cold end face 141, a hot end face 142, a metal conductor 143, an N-type semiconductor 144, a P-type semiconductor 145 and a DC power supply 146. The cold end face 141 and the hot end face 142 The material is an insulating ceramic sheet. The N-type semiconductor 144 and the P-type semiconductor 145 are provided with several groups. 144 and the P-type semiconductor 145 are connected through a metal conductor 143, the metal conductor 143 is close to the inner side of the cold end surface 141 or the hot end surface 142, and the metal conductor 143, the N-type semicond...

Embodiment 3

[0042] Such as Figure 6 , Figure 8 As shown, further optimization is carried out on the basis of a rapid heat transfer miniature thermal shock test device described in Example 1. The test sample mounting base 2 is cylindrical, and the outer diameter of the test sample mounting base 2 is Equal to the inner diameter of the thermal insulation shell 12, at least 2 fixed mounts 23 are evenly distributed in the axial direction along the edge of the upper surface of the test sample mounting base 2, and the fixed mounts 23 include rotatably arranged on the upper surface of the test sample mounting base 2. A longitudinal support rod 231, the top of the longitudinal support rod 231 is rotatably connected with a horizontal telescopic rod 232, and the end of the horizontal telescopic rod 232 is provided with an upper splint 233 and a lower splint 234 arranged up and down, and the upper splint 233 and the lower splint Clamping screws 235 are provided between the splints 234 .

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com