Sucker rod centering device with built-in oil guide channels

An oil guide channel and centralizer technology, which is used in drill pipe, coating, earthwork drilling, etc., can solve the problems of direct contact between the sucker rod and the inner wall of the oil pipe and eccentric wear, the bending of the sucker rod, and the difficulty of the centralizer. Achieve the effect of ensuring normal flow, reducing mutual wear, and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

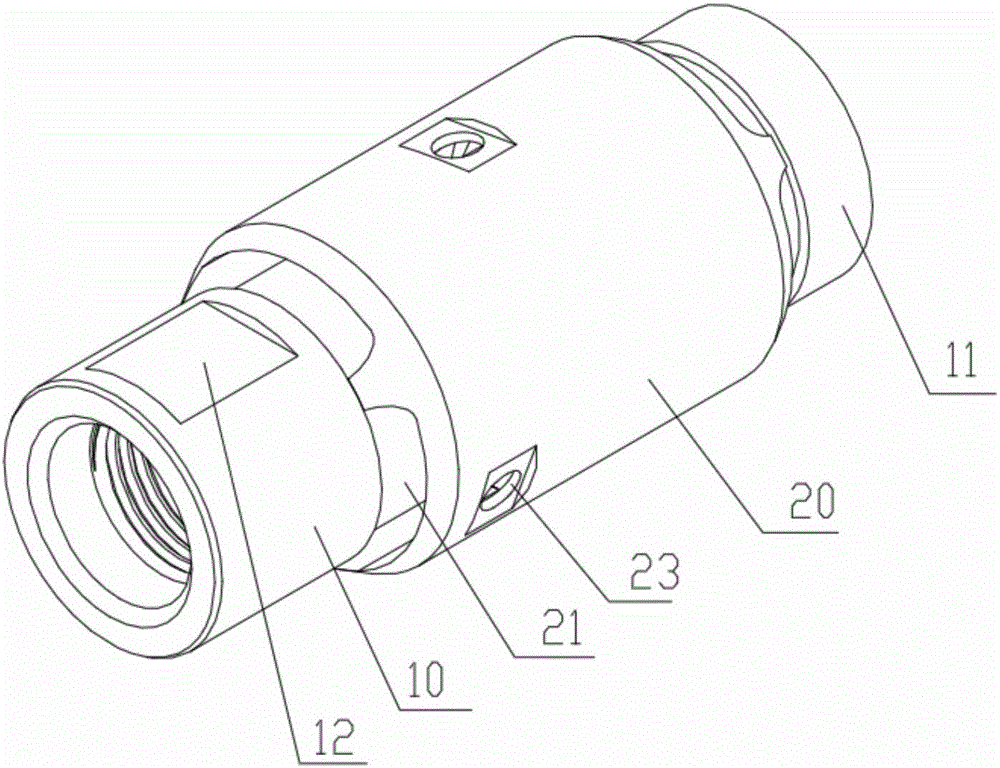

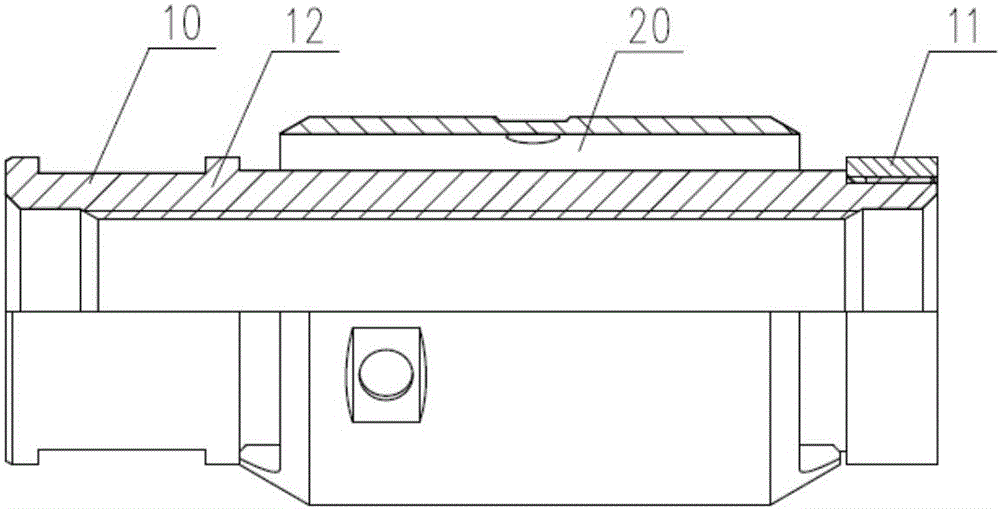

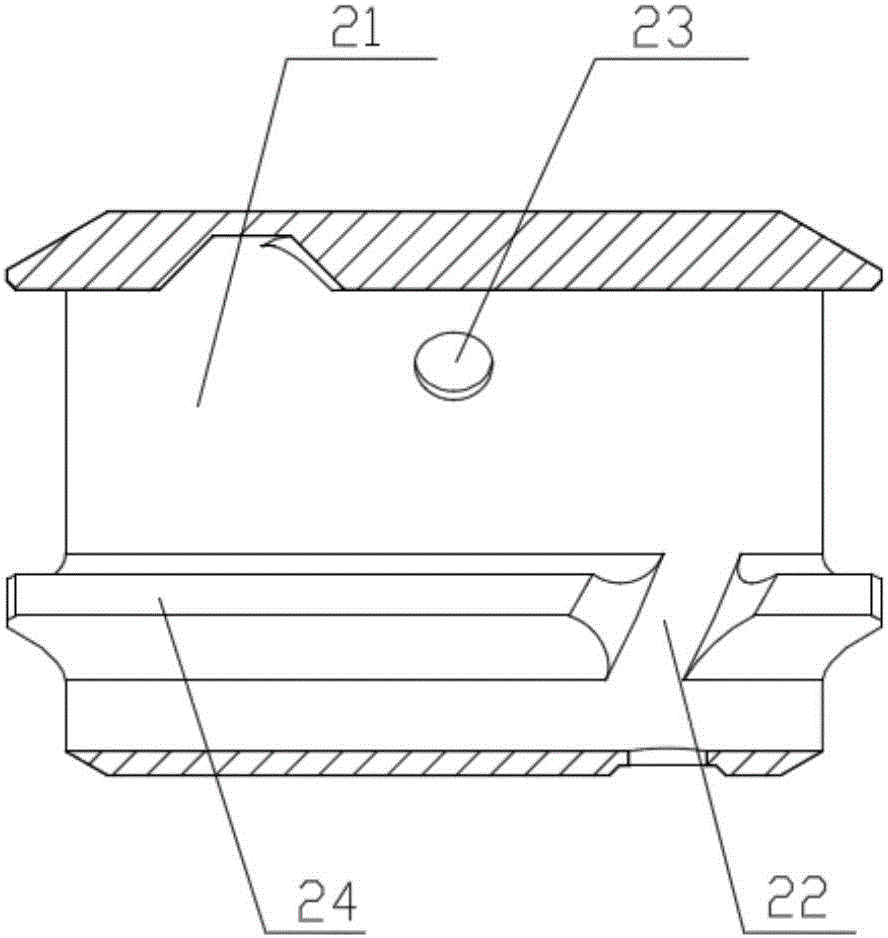

[0032] see Figure 1-12 As shown, a sucker rod centralizer with a built-in oil guide channel provided in this embodiment includes a core rod 10 and a centralizing sleeve 20, the centralizing sleeve 20 is set on the core rod 10, and a fixed The lock ring 11 and the stopper 12, the centering sleeve 20 are located between the fixed lock ring 11 and the stopper 12, and the outer diameter of the centering sleeve 20 is smaller than the inner diameter of the oil pipe, and the gap between the centering sleeve 20 and the oil pipe can be used for the centering sleeve 20 rotates in the oil pipe; the inner surface of the centralizing sleeve 20 is provided with an oil guide passage 21 and an oil passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com