A kind of tunnel segment rapid assembly equipment and assembly method thereof

A tunnel segment and segment assembly machine technology, applied in tunnels, shaft equipment, mining equipment, etc., can solve problems such as inflexible movement and large tunnel space, to ensure structural strength, protect against damage, and solve lining progress problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

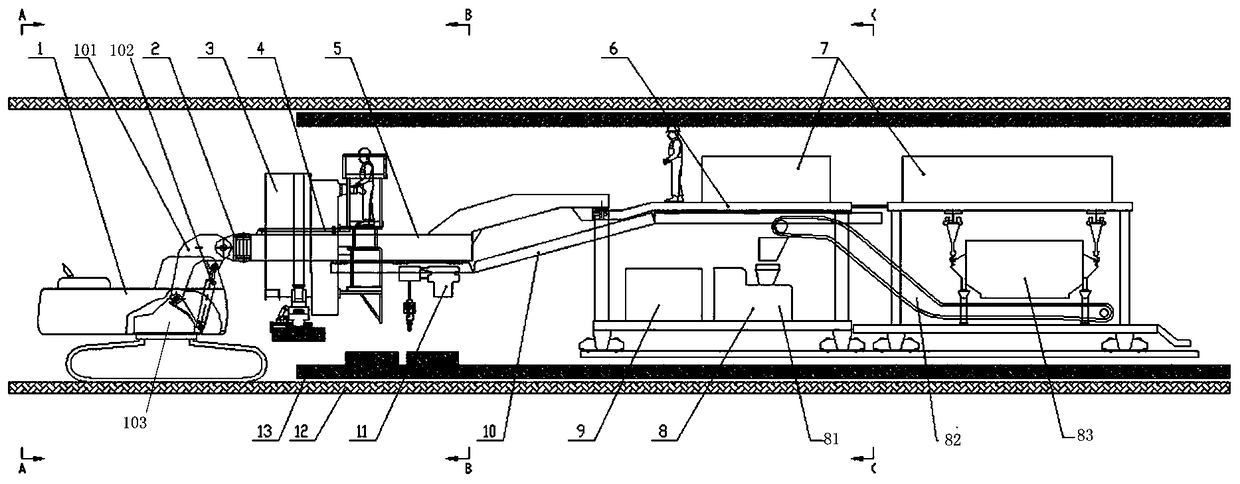

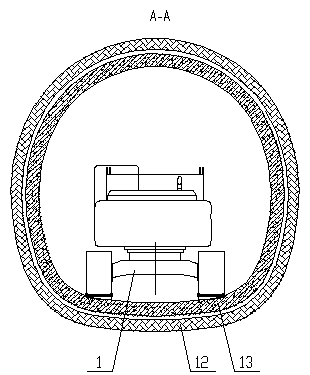

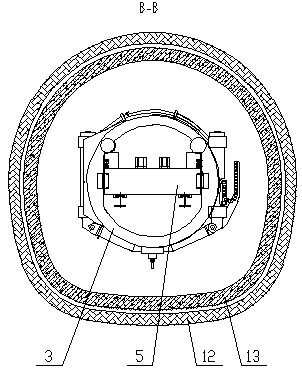

[0019] Such as Figure 1 to Figure 4 As shown, a tunnel segment rapid assembly equipment includes a traveling host 1, a support arm 101, a segment assembly machine 3, a main arm 5, a segment crane 11 and a trailer 6, and the main arm 5 passes through a cross hinge The ear 2 is connected to the upper end of the support arm 101, the lower end of the support arm 101 is hingedly connected to the main machine 1, the upper end of the support arm 101 is connected to the main machine 1 through the support cylinder 102, the segment assembly machine 3 is set on the main arm 5, and the front end of the trailer 6 Connected with main engine boom 5, segment crane 11 is arranged below segment crane beam 10, and the two ends of segment crane beam 10 are connected with main engine boom 5 and trailer 6 respectively. The main engine boom 5 is connected with the support arm 101, and the position of the main engine boom 5 can be stretched and retracted by the support cylinder 102, and slewing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com