Coal bed blind alley enclosing wall and blind alley anti-explosion method using same

A technology for closing walls and blind alleys, which is applied in dust prevention, earthwork drilling, and fire prevention. It can solve problems such as coal spontaneous combustion and gas explosions, and achieve the effect of ensuring a safe state and eliminating hidden dangers of coal spontaneous combustion or gas explosion accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

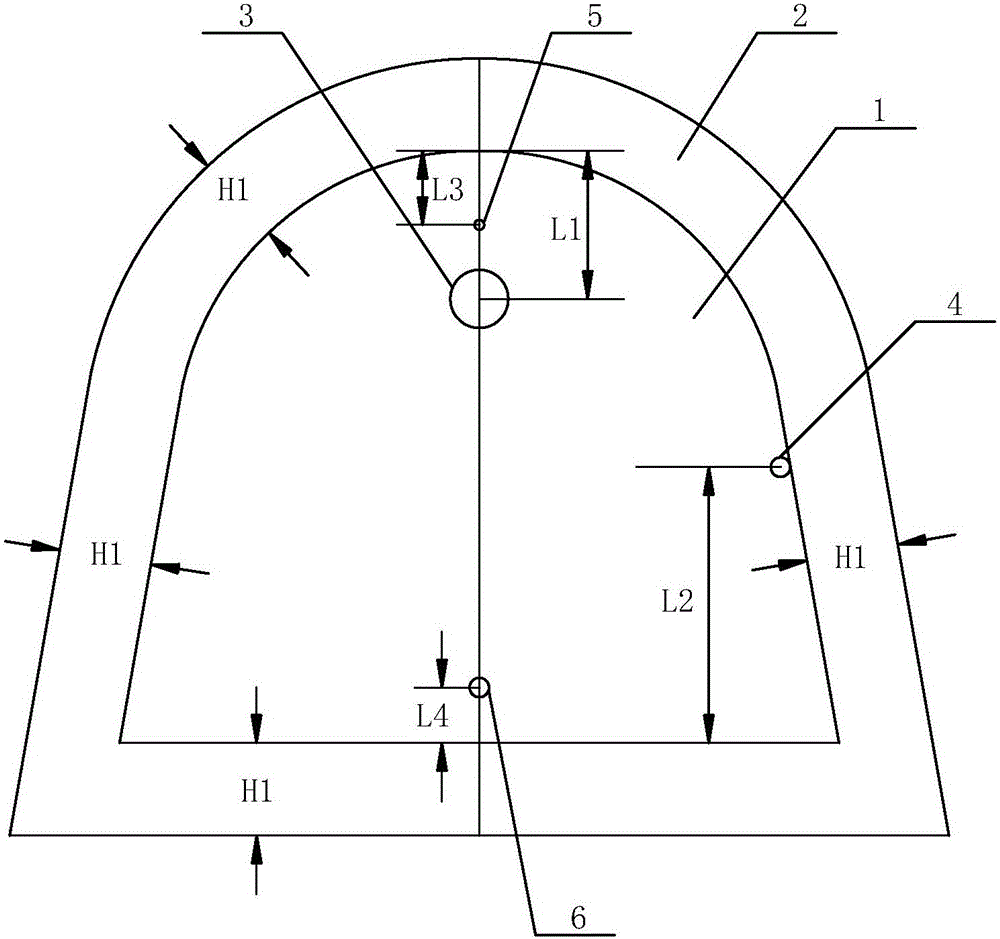

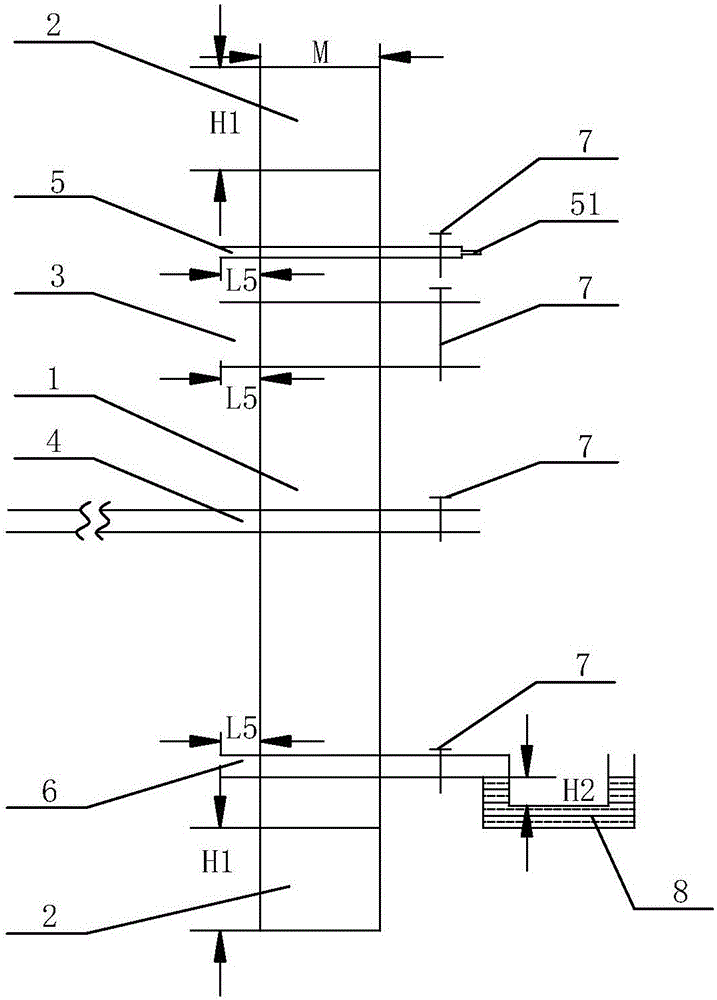

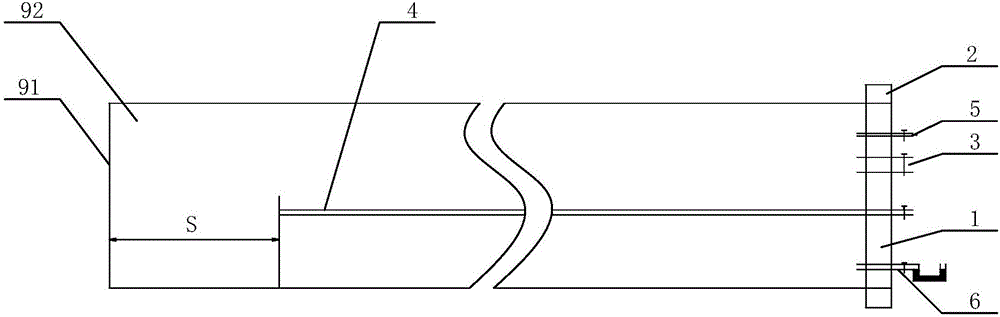

[0027] figure 1 The front view of the closed wall of the coal seam blind road provided by the embodiment of the present invention, figure 2 The left view sectional view of the closed wall of the coal seam blind road provided by the embodiment of the present invention, image 3 A side view of a coal seam blind alley closing wall provided in the blind alley provided by the embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, this embodiment provides a coal seam blind alley closed wall, including: a wall 1 and an embedded part 2 arranged on the periphery of the wall 1, the wall 1 is used to embed the blind alley wall through the embedded part 2, and the wall 1 It is perpendicular to the extending direction of the blind alley 92 . The wall 1 is provided with a gas extraction pipe 3, an inert gas injection pipe 4, an observation pipe 5 and a water discharge pipe 6 perpendicular to the direction of the wall 1. The gas extraction pipe 3, the inert gas inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com