A continuously variable valve drive device and its control method

A technology of a driving device and a control method, which is applied in the directions of engine control, valve device, combustion engine, etc., can solve the problem that the variable valve lift cannot be continuously variable, and achieve continuous controllability and stability of the valve lift and opening time. Good, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

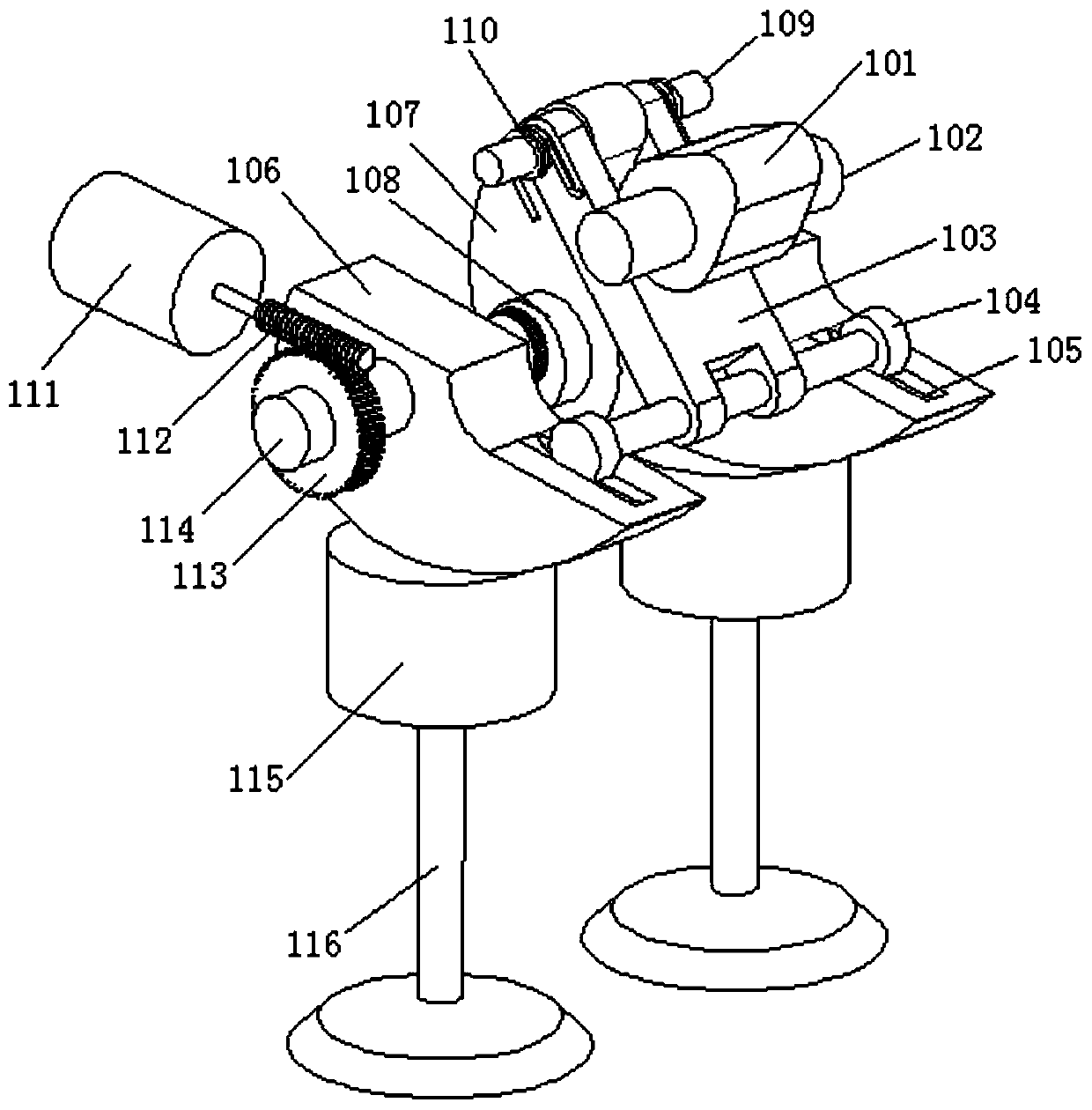

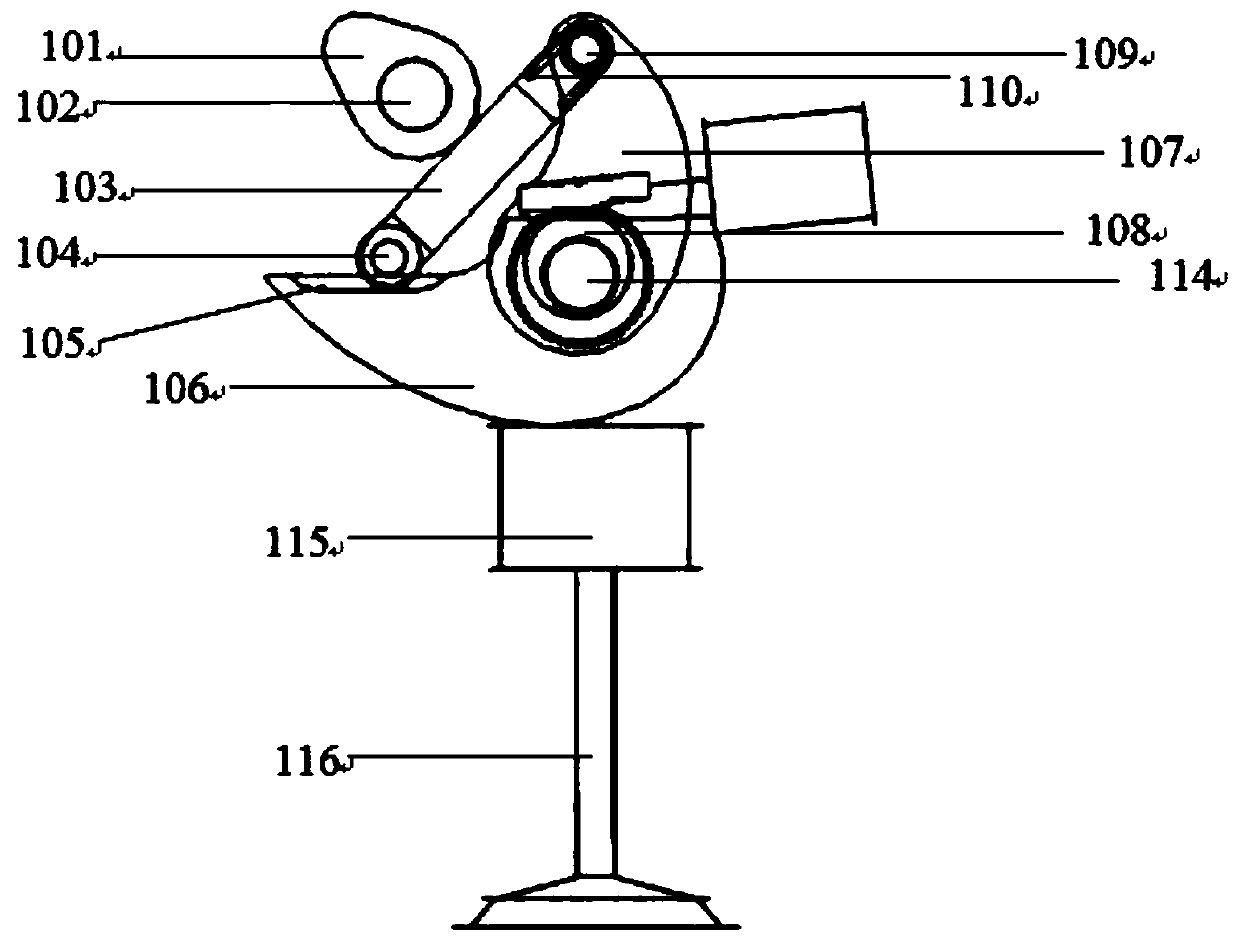

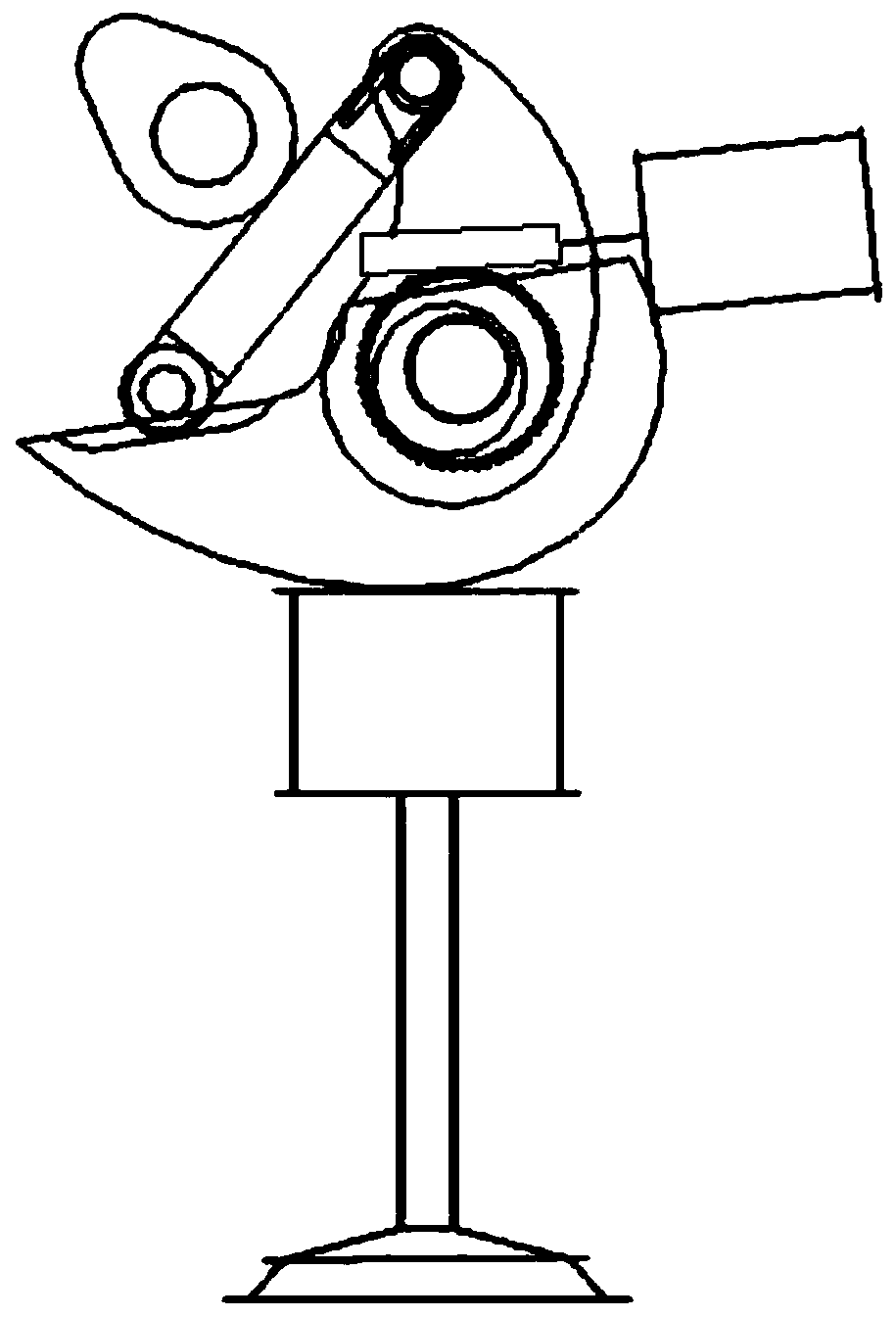

[0047] Such as figure 1 , Figure 8 As shown, the present invention provides a continuously variable valve driving device. A set of variable multi-link mechanism is installed between the first cam 101 and the tappet 115. The tappet 115 is connected with the valve 116. The first The cam 101 is provided with a camshaft 102, and the camshaft 102 rotates driven by the automobile engine, and then drives the first cam 101 to rotate. The first cam 101 drives the variable multi-link mechanism to move, and then drives the tappet 115 and the valve 116 to move up and down, realizing the opening and closing of the valve. Through the shape change of the variable multi-link mechanism, the valve lift and phase can be continuously variable.

[0048] Such as Figure 1-4 As shown, the vari...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap