Aircraft engine fuel-to-oil integrated heat exchange device

A technology of aircraft engine and heat exchange device, which is applied in the direction of engine lubrication, machine/engine, engine function, etc., can solve the problems of bloated product structure, reduced reliability, messy pipeline, etc., achieve compact structure, improve reliability, The clear effect of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

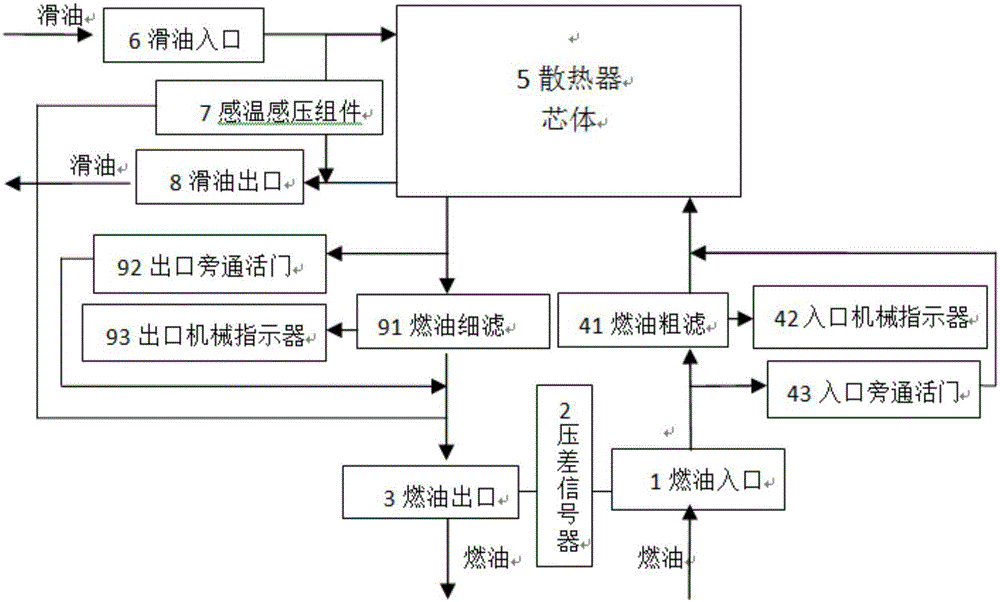

[0010] When the product is working, the low-temperature fuel flows from the fuel inlet 1 into the primary fuel filter 41 of the product, and then enters the radiator core 5 after being filtered by the primary fuel filter assembly 41. When the clogging pressure of the primary fuel filter 41 exceeds the first threshold of the primary filter, the mechanical Indicator 42 sends out an alarm signal. When the clogging pressure of the primary fuel filter 41 exceeds the second threshold value of the primary filter, the inlet bypass valve 43 is opened under the influence of the oil pressure, and the fuel no longer flows through the primary fuel filter 41, and directly flows into the radiator core 5 through the inlet bypass valve 43. heat exchange. The fuel oil after heat exchange flows out from the radiator core 5, and flows out from the fuel outlet after being filtered by the fine fuel filter 91. When the clogging pressure of the fine fuel filter 91 exceeds the first threshold of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com