Detachable chassis fuel tank structure

A fuel tank and underframe technology, which is applied in the field of detachable underframe fuel tank structure, can solve the problems of inoperability, surface paint peeling off, unstable speed, etc., and achieve the effects of reduced operating costs, long service life, and easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

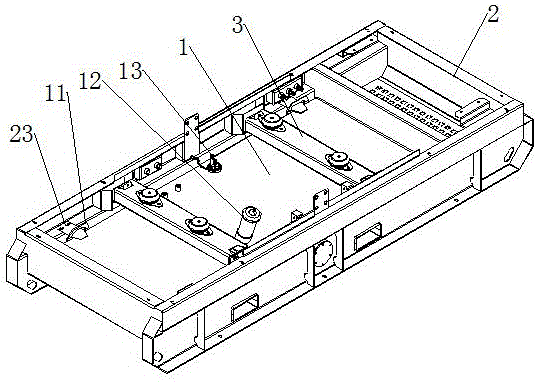

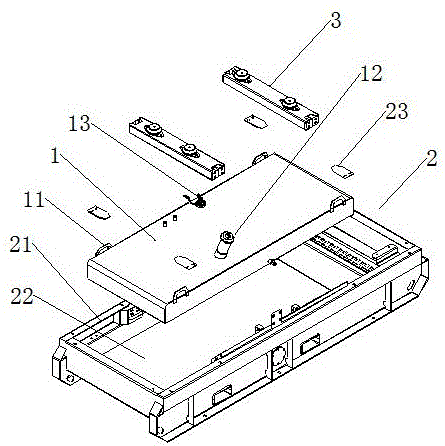

[0015] like figure 1 and figure 2 The shown detachable underframe fuel tank structure includes the underframe fuel tank body 1 and the rectangular chassis frame 2 for installing the underframe fuel tank body 1, and the side and lower end surfaces of the rectangular chassis frame 2 are respectively provided with protective sides Plate 21 and chassis protection plate 22, the upper end surface of the underframe oil tank body 1 is fixed with four handles 11 for easy handling of the underframe oil tank body 1, and the protective side plate 21 of the rectangular chassis frame 2 is installed with corresponding The four fuel tank fixing plates 23 of the four handles 11, and the fuel tank fixing plates 23 are installed on the protective side plates 21 of the rectangular chassis frame 2 through bolts, and the chassis fuel tank body 1 is placed on the chassis pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com