Quick Response Air-Hydraulic Cylinder

A fast-response, gas-liquid cylinder technology, used in engine sealing, fluid pressure actuation devices, engine components, etc., can solve problems such as unsatisfactory gas-liquid cylinder sealing effects, improve sensitivity and stability, and improve use. Longevity, mutual leakage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

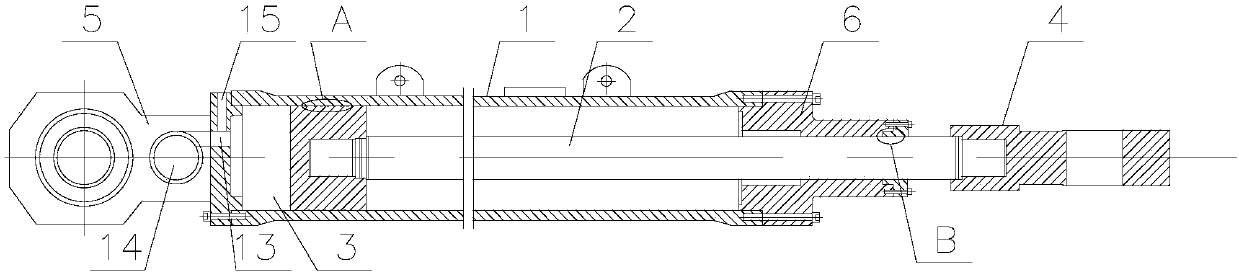

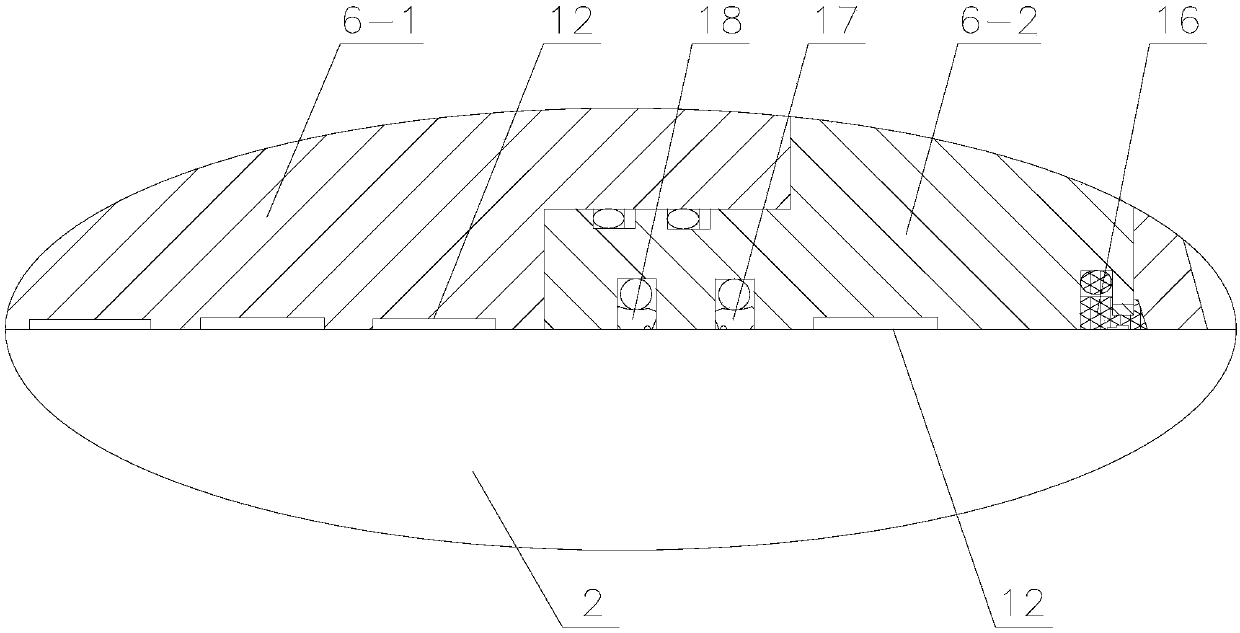

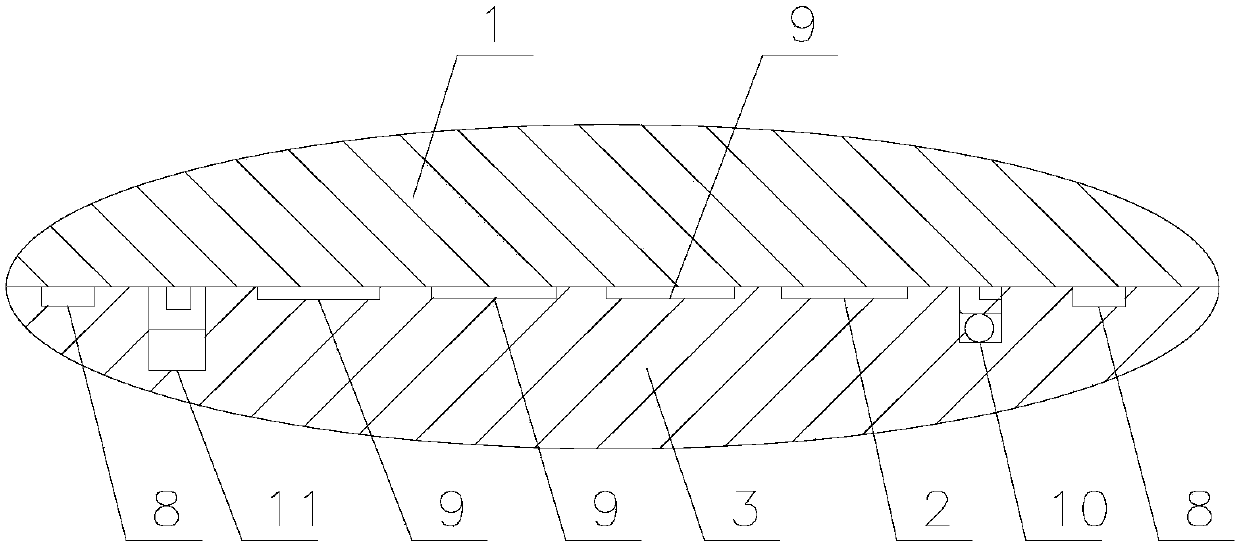

[0017] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0018] Such as Figure 1-3 As shown, a quick-response gas-liquid cylinder of the present invention includes an upper cover 5, a cylinder barrel 1 and a lower cover 6 connected in sequence, and the side of the lower cover 6 away from the cylinder barrel 1 is provided with a push-pull rod joint 4, so The inner axis of the cylinder 1 is provided with a piston 3 cooperating with the inner wall of the cylinder 1, and the end of the piston 3 close to the lower cover 6 is provided with a piston rod 2, and the piston rod 2 is arranged along the axis of the cylinder 1. It extends through the lower cover 6 and is threadedly connected with the push-pull rod joint 4, and also includes a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com