An Elastic Tilting Pad Sliding Bearing

A sliding bearing and elastic technology, which is applied to shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of high cost and complex processing process of elastic tilting pads, so as to reduce maintenance costs, ensure flexible operation, and reduce manufacturing costs. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

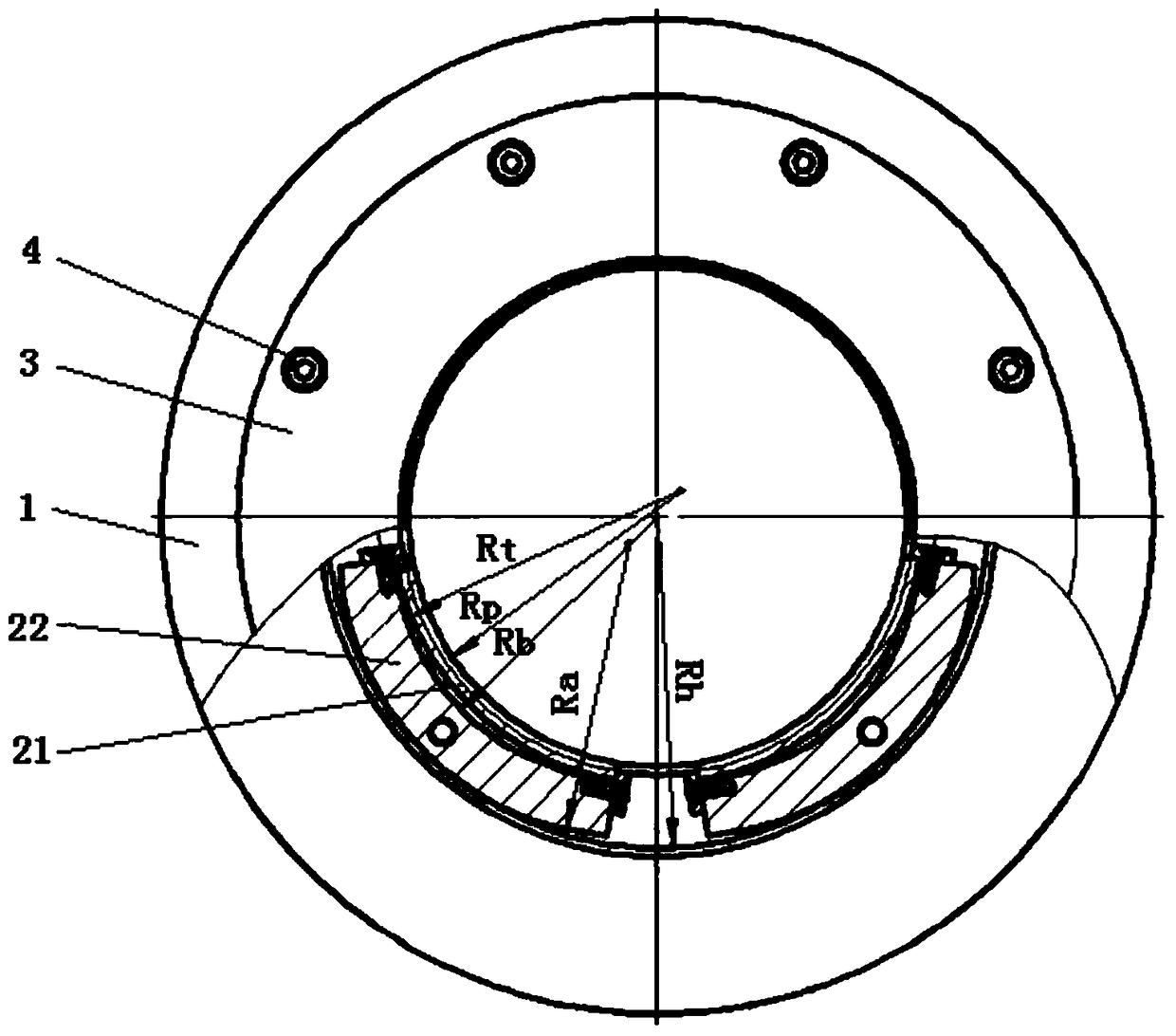

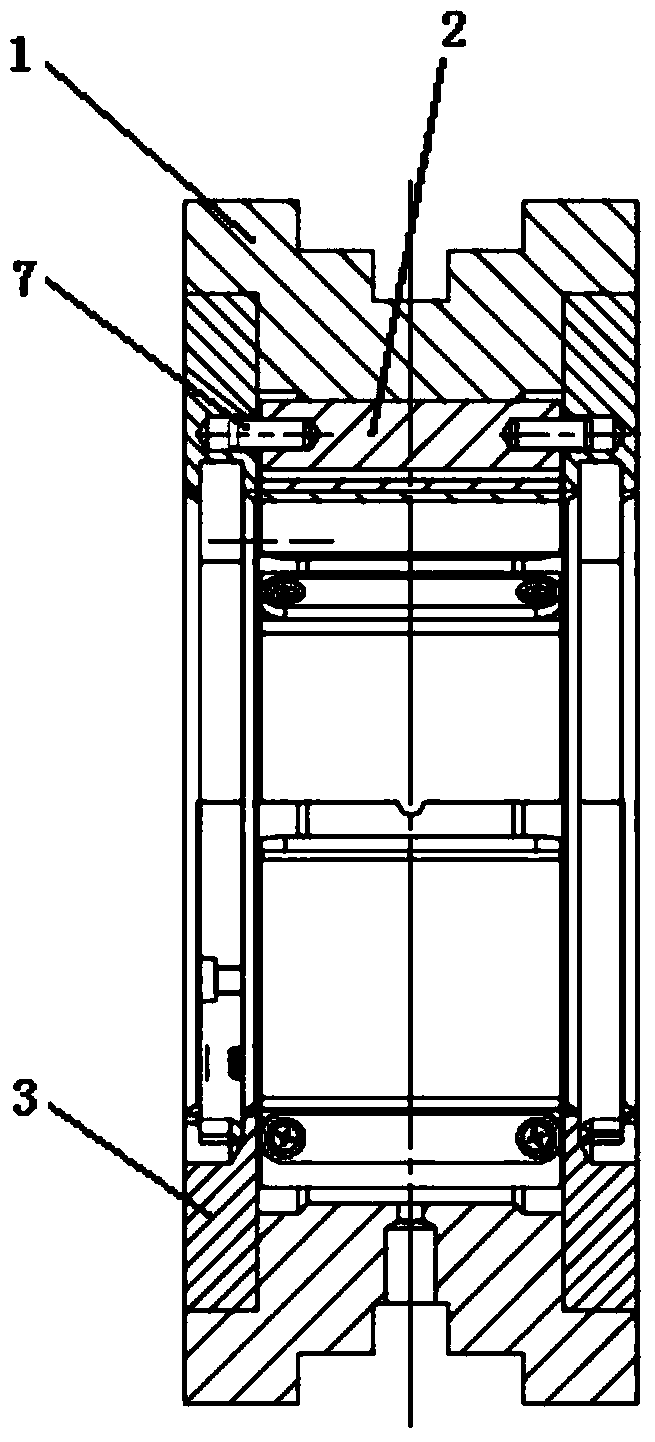

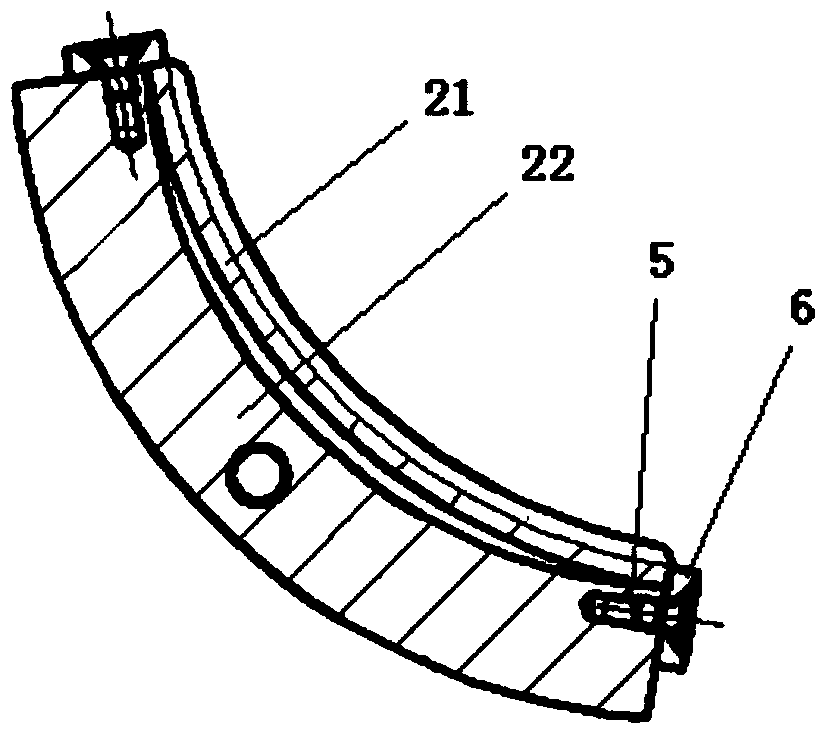

[0025] Referring to the accompanying drawings, the present invention is realized in the following way: an elastic tilting pad sliding bearing, which includes a bearing body 1, an elastic tilting pad 2 and a bearing cover 3; the elastic tilting pads 2 are several and symmetrically arranged on the bearing The inner side of the body 1, the bearing cover 3 is arranged on both sides of the elastic tilting pad 2 and fitted with the two sides of the bearing body 1; each of the elastic tilting pads 2 includes a The elastic body 21 is provided with an installation gap between the elastic body 21 and the tilting pad 22.

[0026] Such as figure 1 As shown, the outer diameter Ra of the tilting pad 22 of the present invention is smaller than the inner diameter Rh of the bearing body 1, and the tilting pad 22 can tilt on the inner side of the bearing body 1 with the pin shaft 7 as the center; the outer diameter of the elastic body 21 Rt and the inner diameter Rp of the elastic body 21 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com