Hydrogen storage device utilizing metallic compound

A technology of metal compound and metal compound layer, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, geometry/arrangement/size of container structure, etc., can solve problems such as energy consumption, increase storage capacity, solve The effect of security concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

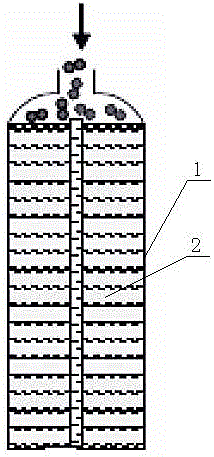

[0010] Metal compound hydrogen storage device of the present invention such as figure 1 As shown, the hydrogen storage tank 1 is provided with a metal compound layer 2, and the metal compound layer 2 is a metal hydride fine powder. Metal hydride (LaNi4.25Al0.75) fine powder repeats hydrogen absorption and desorption actions, after 1 cycle (left picture) and 10 cycles. Metal hydride expands hydrogen during absorption and forms alloy hydrogen after release, and its expansion and contraction process cannot be excessively restricted. If a large amount of metal hydride powder is present due to expansion restrictions or lack of space, the pressure will be on the container walls and may eventually deform or damage the container. How to increase the stored hydrogen density is the most critical issue. Hydrogen storage using alloy hydrogen is a thermally driven process. The heat needs to be disposed of during the hydrogen charging and discharging process. Heat transfer during hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com