Multi-criterion multi-boiler coordination optimizing control system based on energy efficiency of boilers

A coordinated optimization, multi-criteria technology, applied in the control system, control combustion, energy industry and other directions, can solve problems such as large boiler load deviation and unstable pressure of the main pipe, and achieve economical, equipment stability, and reasonable resource allocation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

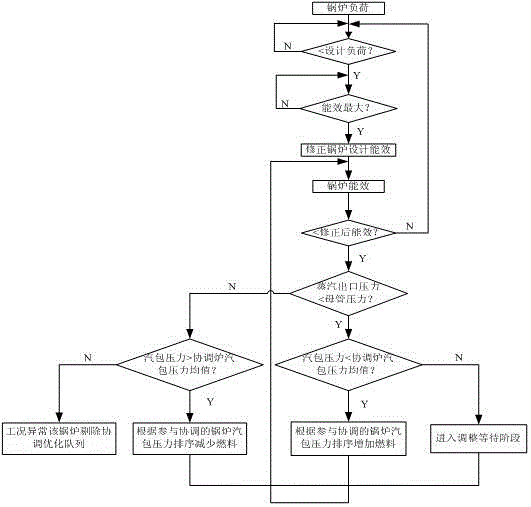

[0018] Statistical Modification Model of Boiler Energy Efficiency

[0019] According to the current boiler load, steam drum pressure, outlet steam pressure, furnace temperature and exhaust gas temperature real-time collection, after a judgment period T 1 , under the condition that the boiler is relatively stable, the statistics of the current boiler energy efficiency η 1, Let η max =η 1, Increase the amount of fuel ∆F 1 , and then after a judgment cycle T 2 Finally, calculate the boiler energy efficiency η 2, If η 2 >η 1 Then η max =η 2; If η 2 1 Then η max =η 1 , after four consecutive judgment cycles, if η 2、 n 3、 n 4、 n 5 are less than η 1, Then η max =avg(η 1、 n 2、 n 3、 n 4、 n 5 ).

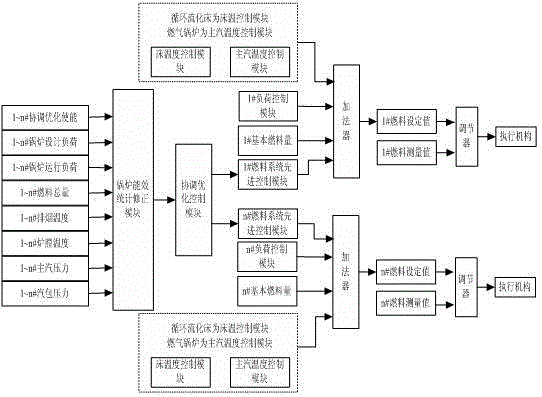

[0020] Coordinated Optimization Control Module

[0021] Taking 4 boilers participating in coordinated optimization as an example, in η n maxn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com