Pipeline contourgraph and scribing instrument

A profilometer and pipeline technology, which is applied in workshop equipment, mechanical counter/curvature measurement, manufacturing tools, etc. It can solve the problems of inability to continuously monitor deformation and inconvenient operation, and achieve low production cost, convenient operation and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

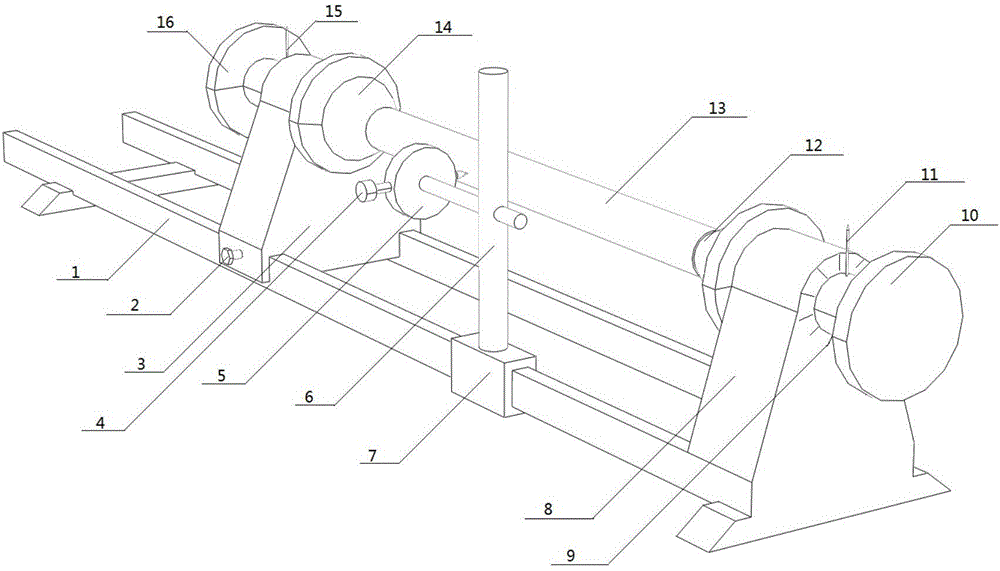

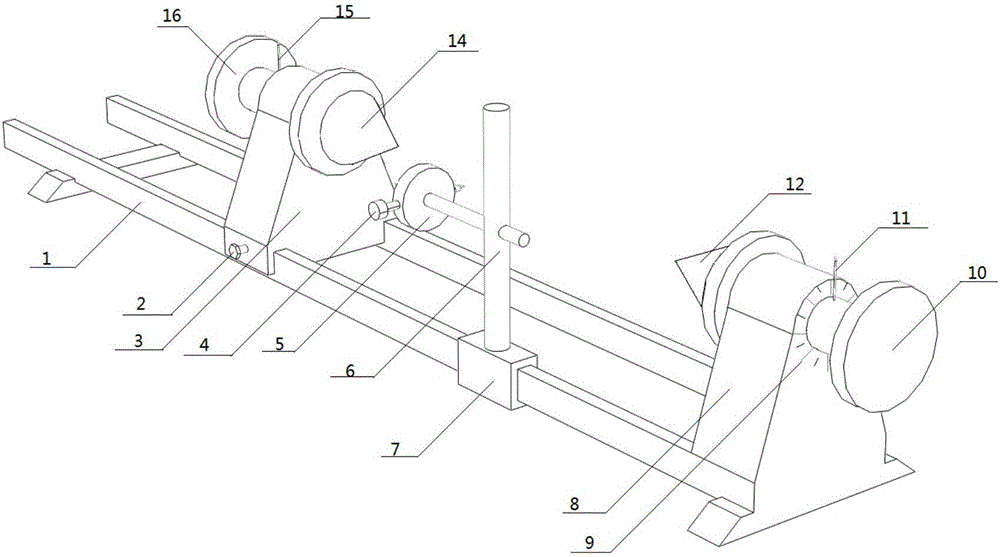

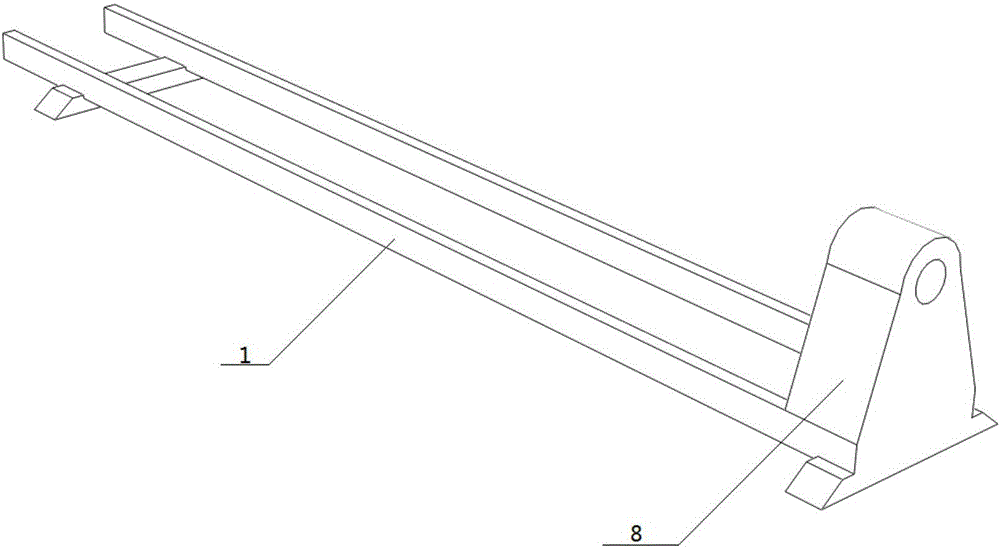

[0027] Below in conjunction with accompanying drawing, the specific embodiment of the present invention will be further described:

[0028] The pipeline profiler of the present invention includes: a guide rail 1, the sliding bracket A 3 is located on the guide rail 1, and can slide along the guide rail. During actual measurement, the sliding bracket A is first moved to the end of the guide rail 1, and a section of the pipe fitting is inserted into the positioning cone A 12, then raise the other end of the pipe fitting until the axis of the pipe fitting is at a horizontal position, then move the movable bracket A inward so that the positioning top cone 14 is inserted into the other end of the pipe fitting, and then tighten the positioning screw 2 after the top is tightened, so that the sliding bracket A It is fixed on the guide rail 11 to prevent the pipe from falling down during the rotation.

[0029] There are two methods for measurement: one is to fix the measurement module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com