A bi-directional two-dimensional floating self-adaptive mechanism for small-diameter high-temperature and high-pressure downhole pipelines

A two-way two-dimensional, self-adaptive technology, applied in the testing of machine/structural components, electromagnetic measuring devices, instruments, etc., can solve the problem of inability to adapt to the detection of underground oil and gas pipelines, and achieve the effect of increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below with reference to the accompanying drawings. The accompanying drawings constitute a part of this application and, together with the embodiments of the invention, serve to explain the principles of the invention.

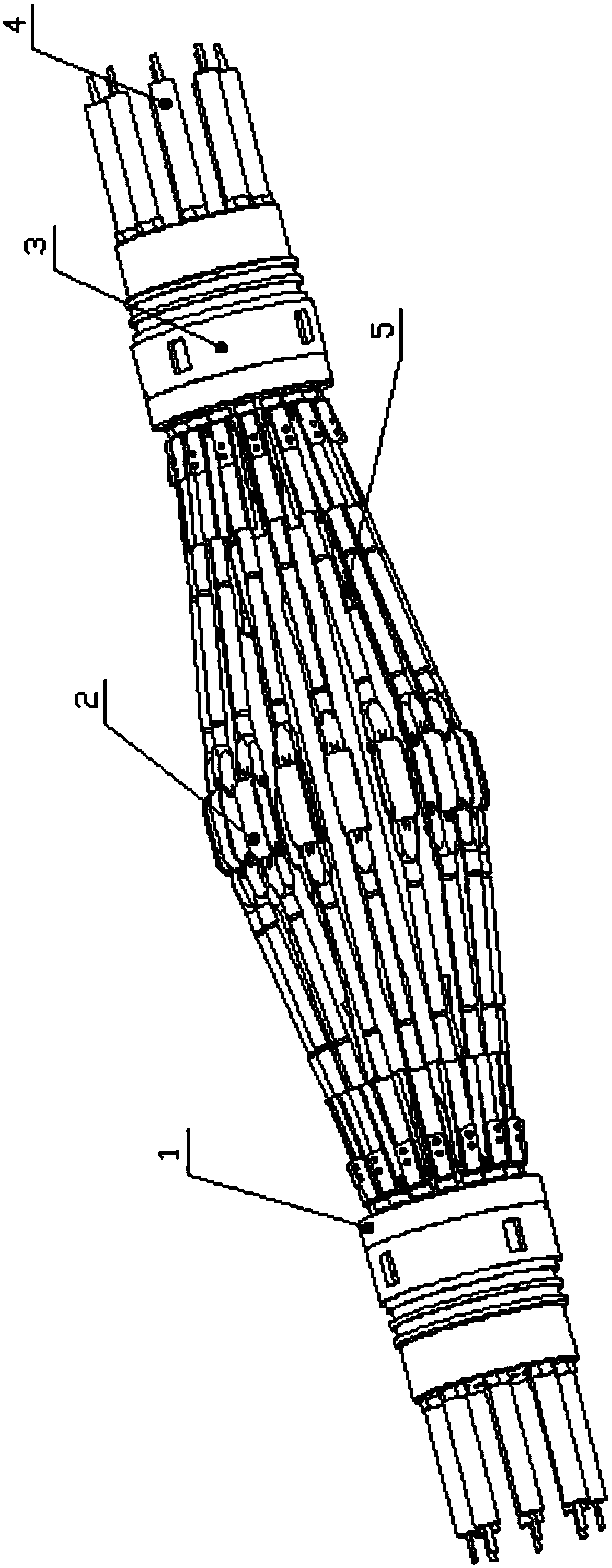

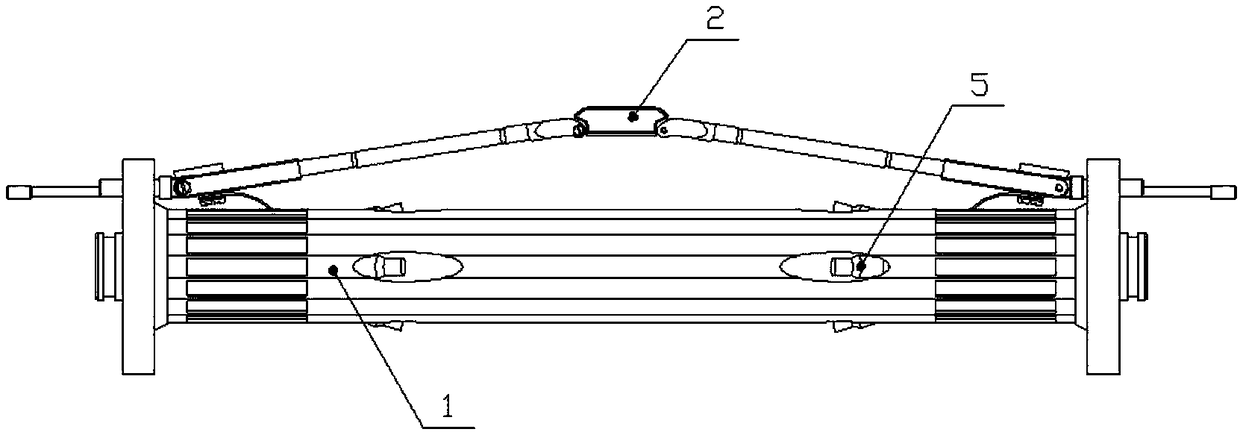

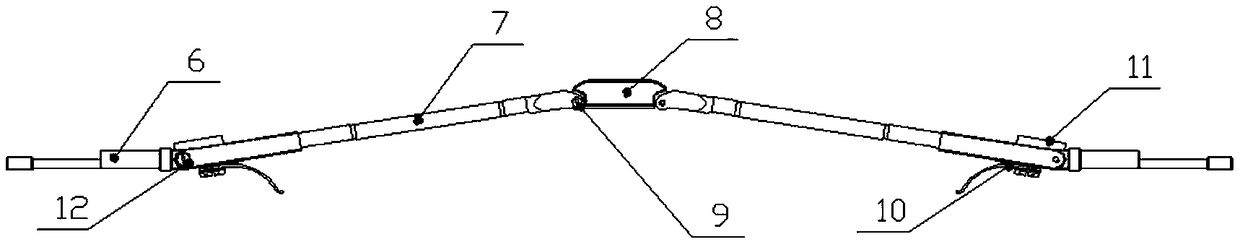

[0050] like Figure 1 to Figure 7 As shown in the figure, a small-diameter two-dimensional two-dimensional floating self-adaptive mechanism for a high-temperature and high-pressure downhole pipeline, the self-adaptive mechanism includes: a central frame 1, a detection arm assembly 2, a sensor base 3, and a displacement sensor 4;

[0051] The central skeleton 1 is hollow inside, with flanges at both ends, and a cylindrical polyhedron in the middle. The two ends are symmetrical. There are 18 flange stepped holes 13 and 8 flanges evenly distributed on the flange. light hole 14;

[0052] Both ends of the central frame 1 are provided with bosses 15, and the side walls of the bosses 15 are provided with seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com