Pyroelectric detection device

A technology of pyroelectric detection and detection tube, which is applied in the direction of measuring device, measuring electricity, measuring heat, etc., can solve the problems of low detection efficiency and low convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to improve the efficiency and convenience of detecting potential safety hazards of machinery and equipment, an embodiment of the present invention provides a pyroelectric detection device. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

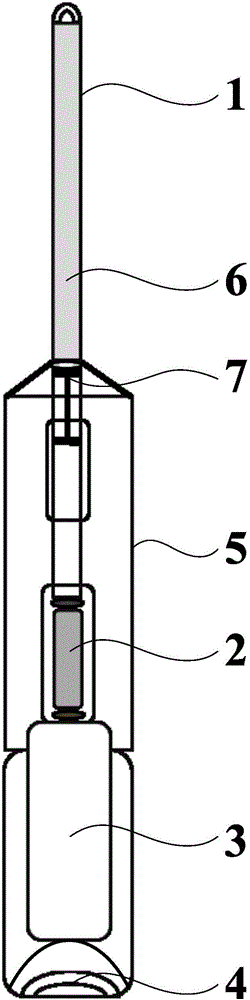

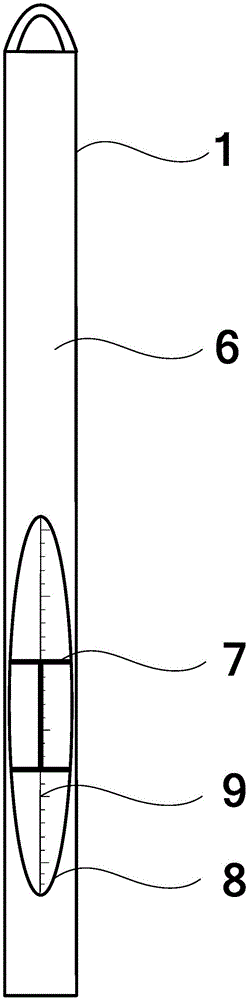

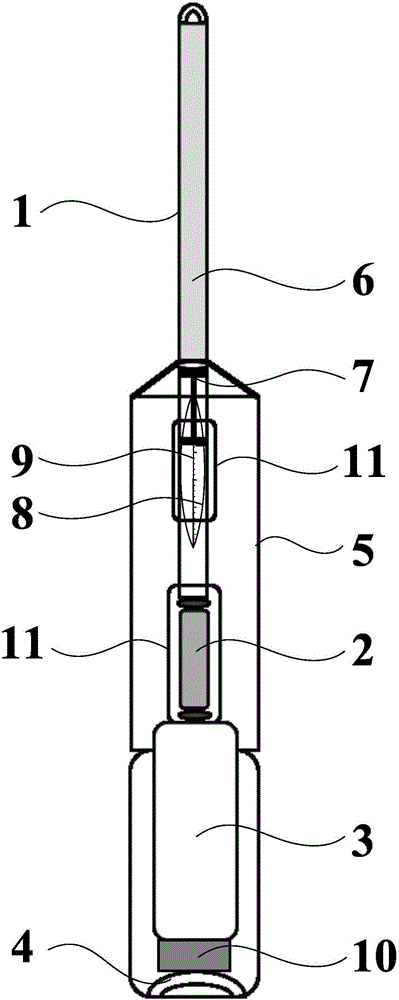

[0033] refer to figure 1 , a pyroelectric detection device provided by an embodiment of the present invention includes a detection tube 1, a neon tube 2, a resistance device 3 and a hand electrode 4 connected in series in sequence, and is coated on the detection tube 1, the neon tube 2, the resistance device 3 and the The hand touches the insulating shell 5 outside the electrode 4, wherein one end of the probe tube 1 is exposed outside the insulating shell 5, the probe tube 1 is filled with a fluid working medium 6, and the side of the probe tube 1 connected to the neon tube 2 is inside The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com