Multifunctional environmental device for fatigue testing

A fatigue test and multi-functional technology, applied in the field of parts fatigue test, can solve the problems of low utilization rate, small application range and high cost, and achieve the effects of reducing test cost, improving test efficiency and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

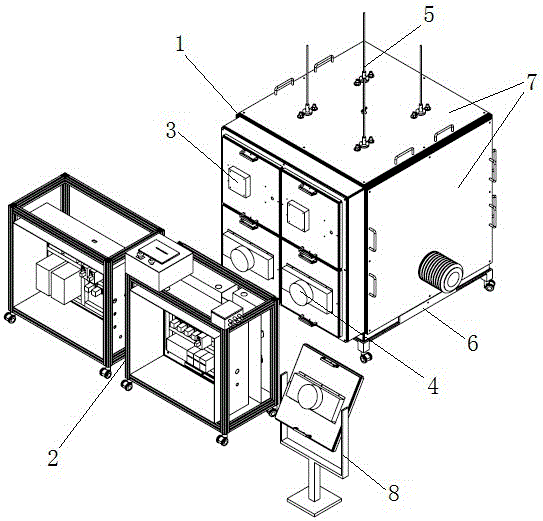

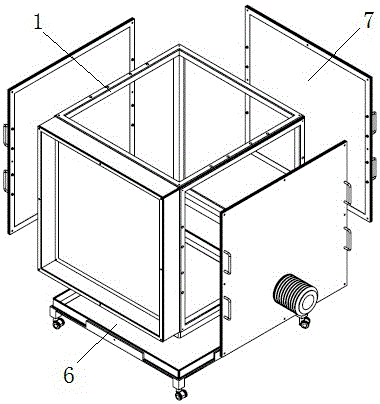

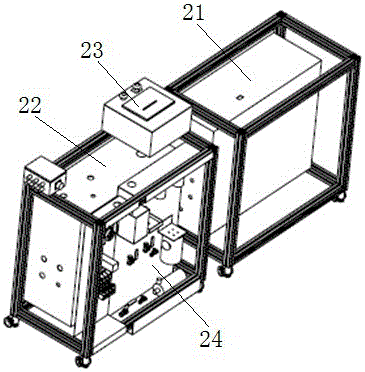

[0020] like figure 1 , 2 , a multifunctional environmental device for fatigue testing, comprising a frame 1 and a control cabinet 2, the frame 1 is a cube frame, the environmental device also includes a heating module 3, a cooling module 4 and a salt spray assembly 5, the frame 1 The bottom surface is sealed with a water-receiving cover plate 6, and any side of the frame 1 is equally divided into several module installation positions. The heating module 3 and / or cooling module 4 are inserted into the module installation positions, and the other sides of the frame 1 and the top surface is equipped with a sealing cover plate 7, the salt spray assembly 5 is installed on any one or more sealing cover plates 7, and the control cabinet 2 is connected to the heating module 3, the cooling module 4 and the salt spray assembly 5 ;

[0021] In the usual fatigue test, an appropriate number of heating modules 3 and cooling modules 4 are selected and assembled on the module installation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com