A method and device for measuring the emulsification ability of crude oil along the process of simulating surfactant flooding

A technology of surfactant flooding and emulsifying ability, applied in the direction of material inspection products, etc., can solve the problems of inability to determine the emulsification state, detachment, inability to prove the emulsification and degree of emulsification of surfactants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

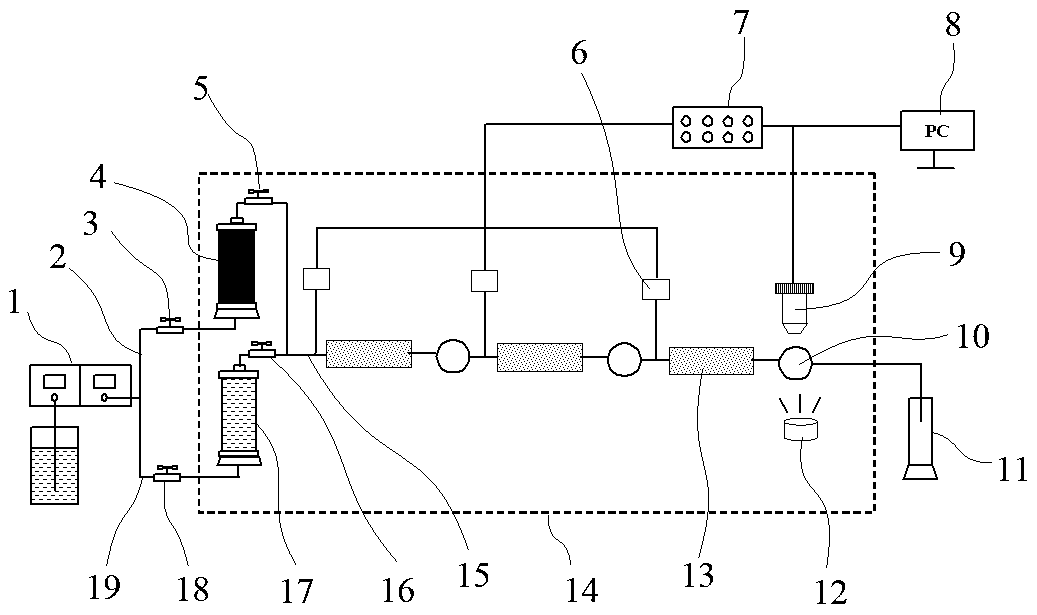

[0028] Such as figure 1 In the shown embodiment, a device for measuring the emulsification ability of crude oil along the process of simulated surfactant flooding includes a pump 1, a constant temperature box 14, a differential pressure data acquisition system 7 and a microscopic observation system. Among them, the pump adopts a constant speed and constant pressure pump. The outlet end of the pump is provided with a crude oil pipeline 2 and a surfactant pipeline 19 arranged in parallel. The crude oil pipeline is provided with a crude oil piston container 4. The front end valve 3 of the container, the outlet end of the crude oil piston container is provided with the rear end valve 5 of the crude oil container, the piston container of crude oil and the rear end valve of the crude oil container are all located in the thermostat, and the front end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com