Electric equipment fault detection method and device

A technology for electrical equipment and fault detection, which is applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., and can solve the problems of inaccurate fault detection of electrical equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

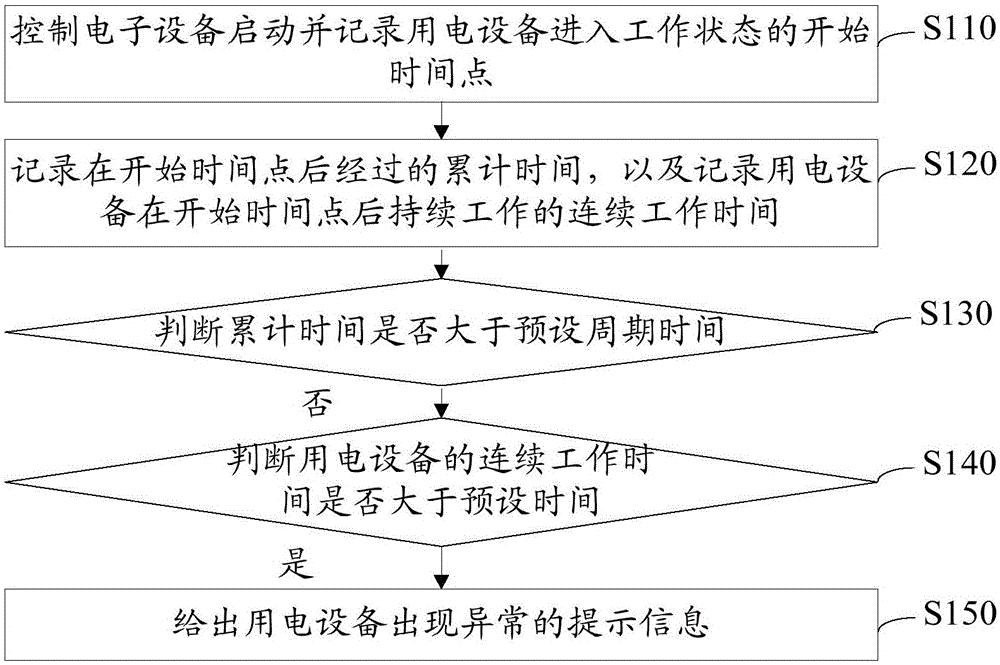

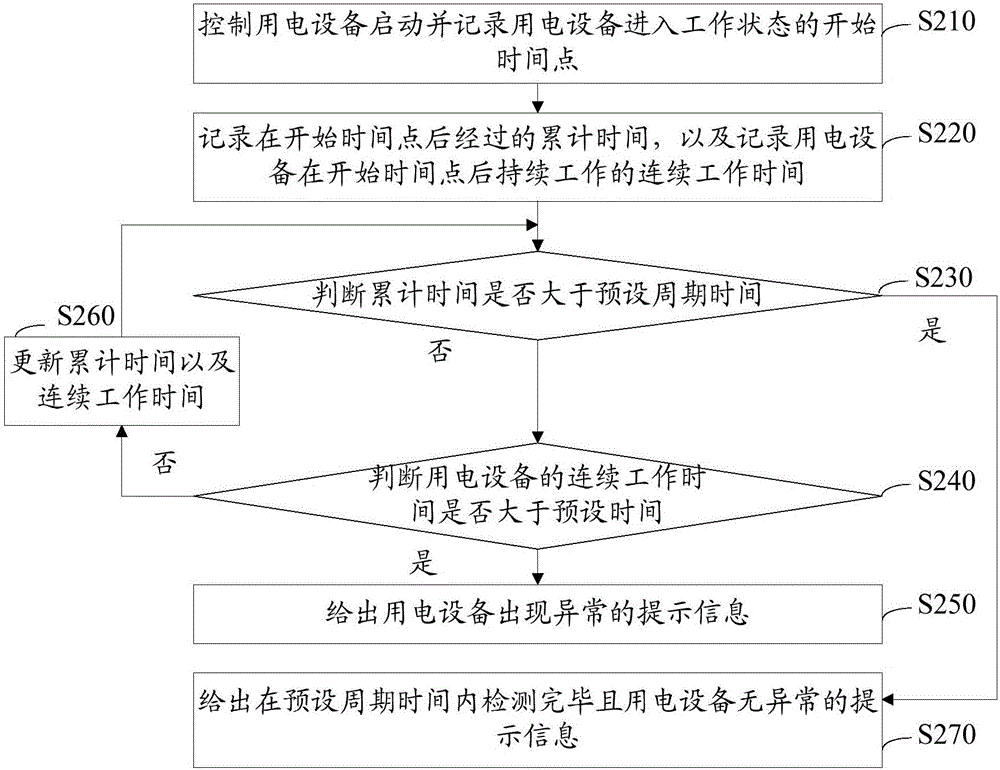

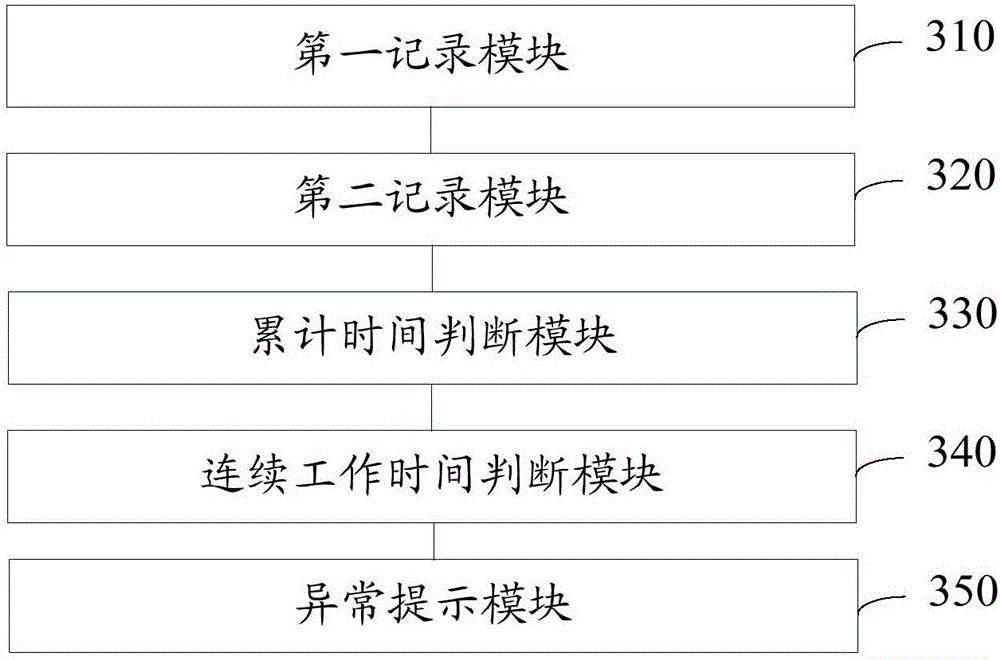

[0022] see figure 1 , providing an embodiment of a fault detection method for electrical equipment, including the following steps:

[0023] S110: Control the startup of the electrical equipment and record the start time point when the electrical equipment enters the working state.

[0024] For some electrical equipment, when the continuous working time exceeds a certain period of time, it will be considered abnormal. The compressor will automatically stop running. When the temperature in the refrigerator rises to the cut-off point temperature, the compressor will resume operation. If the refrigerator compressor does not stop running when the temperature is lower than or equal to the cut-off point temperature, the refrigerator may If the compressor breaks down, on the other hand, that is to say, if the compressor of the refrigerator has been working continuously for more than a certain period of time, it is considered to be broken down. Therefore, in this embodiment, by judgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com