Aluminum armored power cable as well as production equipment and production technology of cable

A technology for producing equipment and power cables, which is applied in the manufacture of power cables, insulated cables, cables/conductors, etc. It can solve the problems of large bending value of cables, inconvenient construction, shortened service life of cables, etc., and achieve the effect of enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

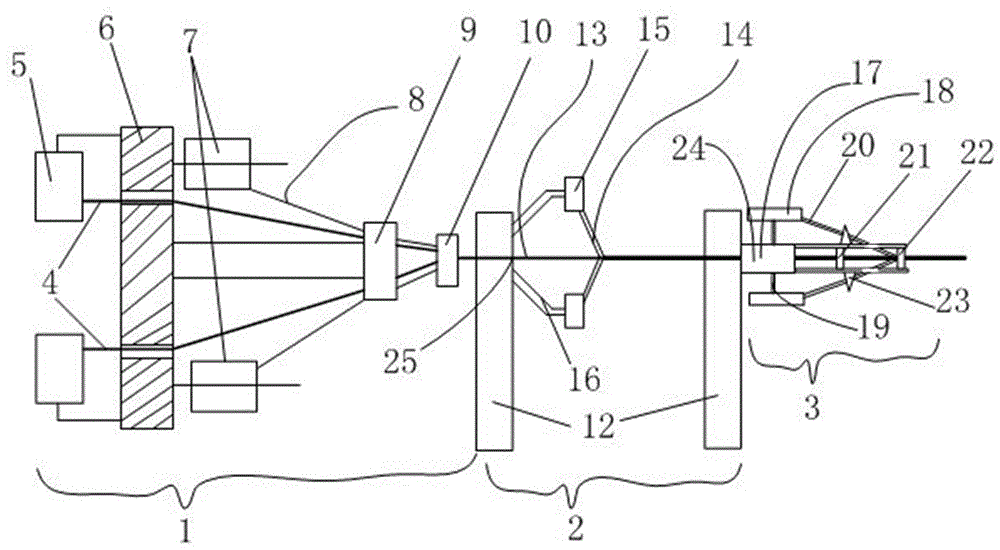

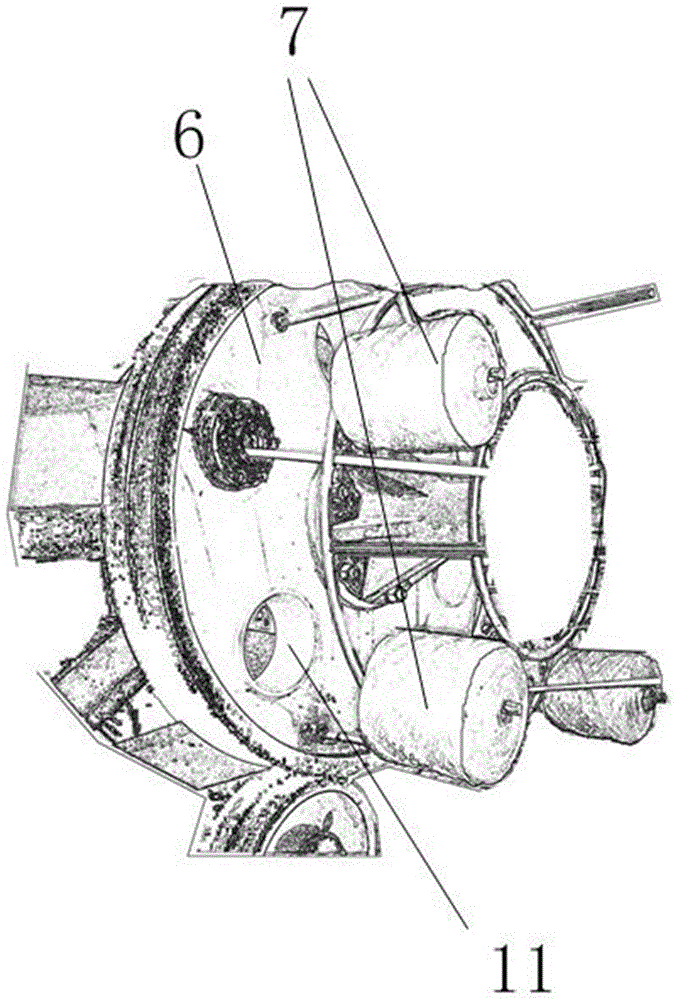

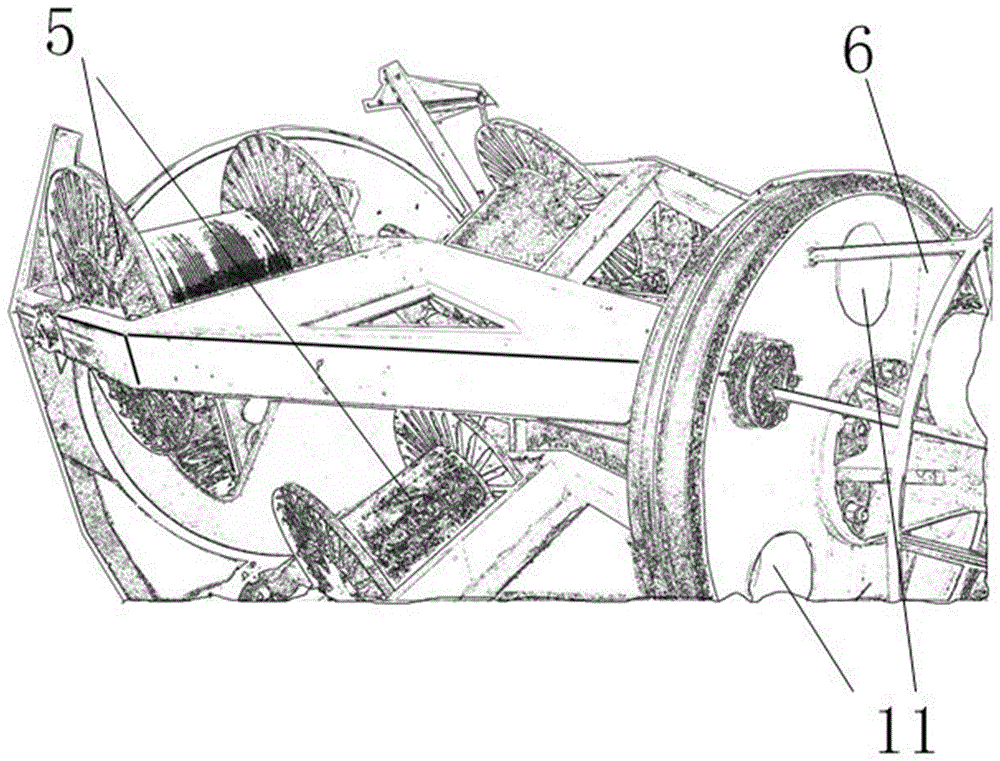

[0032] Such as Figure 1-5 As shown, the aluminum armored power cable and its production equipment and production process, the production equipment is a cable twisting and wrapping device, and the twisting and wrapping device twists and twists the insulated cores 4 that make up the cable. The cable core 13 is sequentially coated with a refractory layer and an aluminum armor layer.

[0033] The twisting and wrapping device includes a conveying mechanism, a twisting mechanism 1, a refractory layer wrapping mechanism 2 and an aluminum armor wrapping mechanism 3, and the conveying mechanism drags the cable core 13 to pass through the twisting mechanism 1, the refractory layer wrapping mechanism, and Bag mechanism 2 and aluminum armor wrapping mechanism 3.

[0034]The aluminum armored power cable is sequentially provided with a cable core 13, a fire-resistant layer and a self-locking aluminum armor layer from the inside to the outside. The cable core 13 is twisted by an insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com