Front-end transfer twisting mechanism

A stranded wire and wire technology, applied in the field of front-end relay stranded wire mechanism, can solve the problems of low speed and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

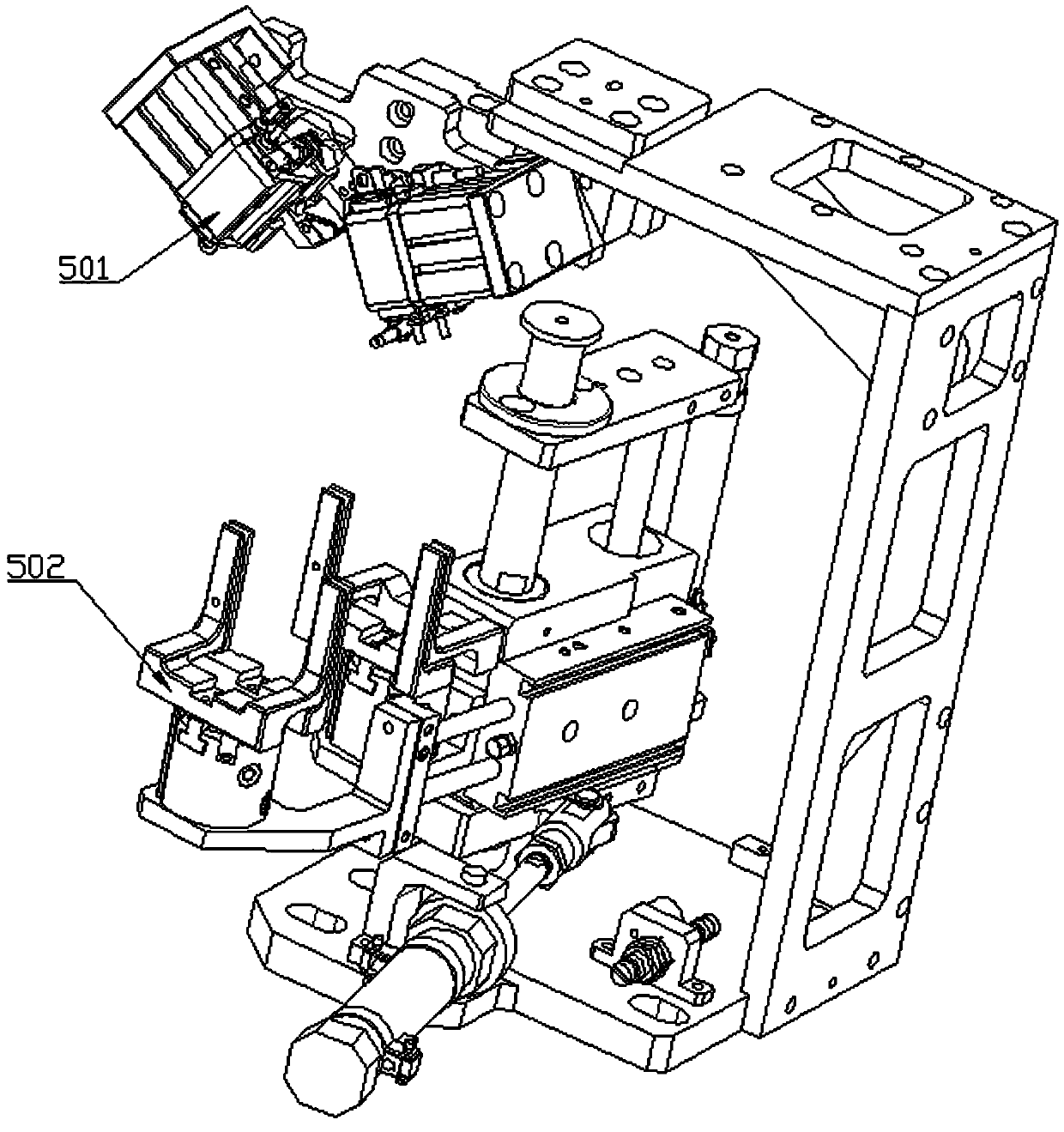

[0014] like Figure 1-3 As shown, a front-end relay twisting mechanism includes a tension measuring and mapping module 501 and a twisting wire relay module 502;

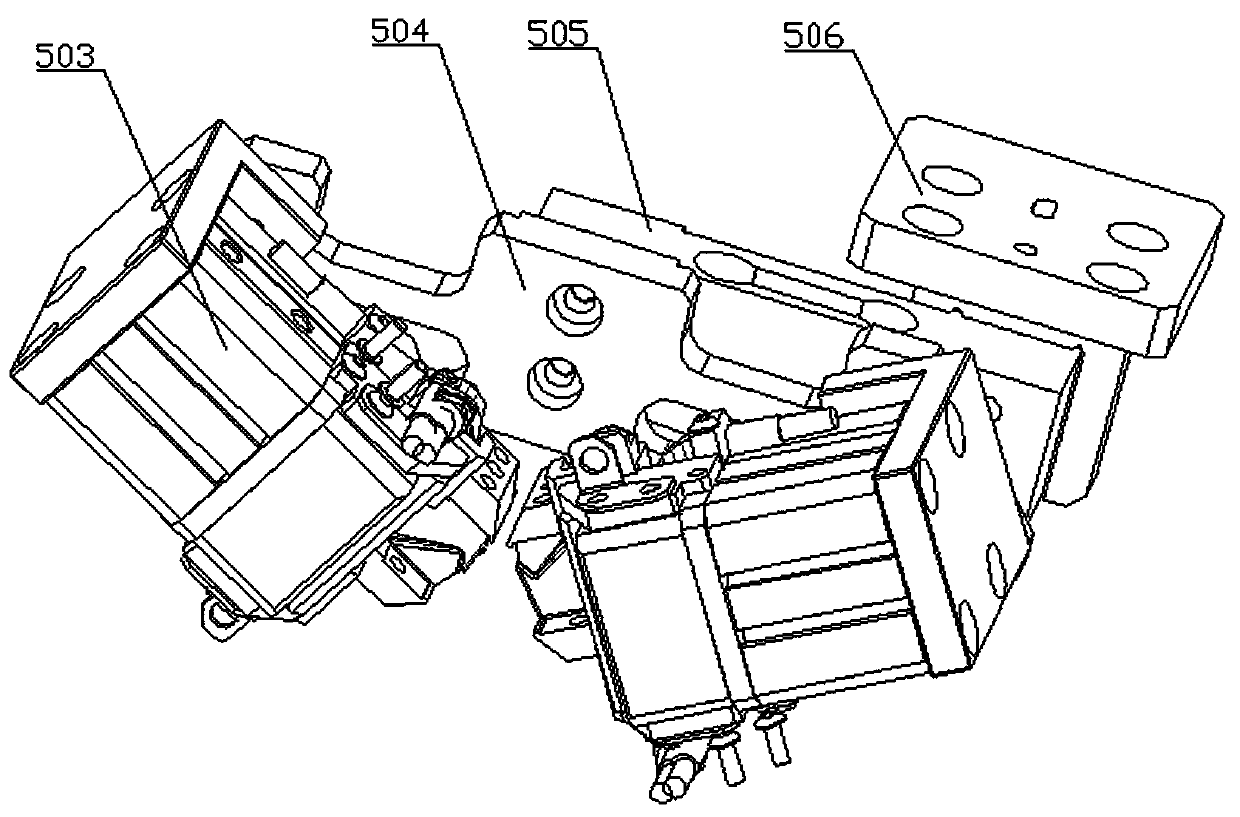

[0015] The tension measurement module 501 includes a clamp mechanism 503, a middle fixed block 504, a tension sensor 505, and a fixed block 506. The fixed block 506 is fixed on the top plate 508 of the strand transfer module 502, and the tension sensor 505 is fixed on the fixed block. 506 , the middle fixing block 504 is fixed on the side end of the tension sensor 505 , and the two ends of the middle fixing block 504 are oppositely provided with a jaw mechanism 503 .

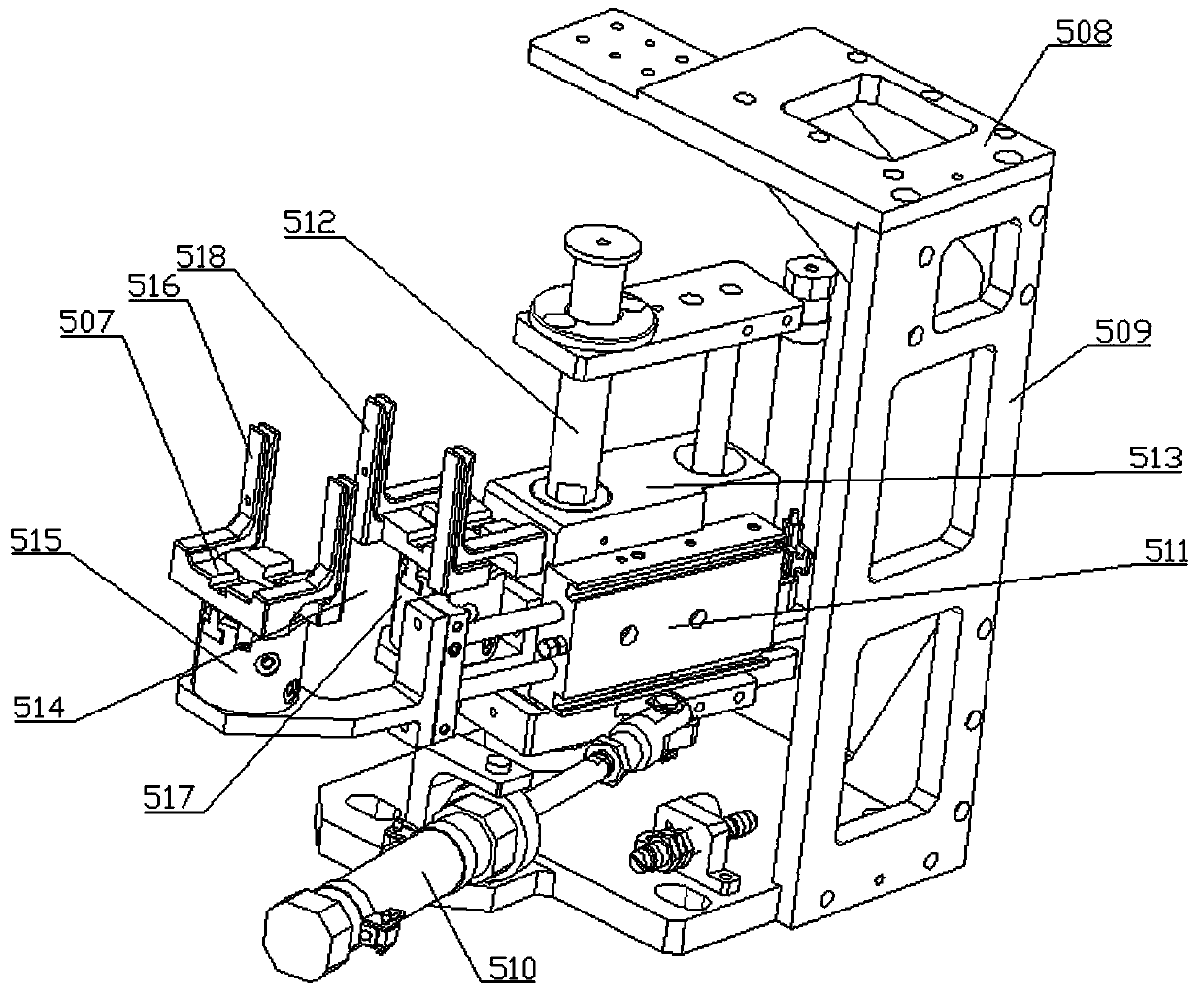

[0016] The stranded wire relay module 502 includes a relay module 507, a top plate 508 and a vertical plate 509; the vertical plate 509 is fixed on the bottom plate of the relay module 507, and the top plate 508 is fixed on the vertical plate 509; the relay module 507 includes Bottom plate, pen-shaped cylinder I510, double-rod cylinder 511, rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com