A kind of preparation method and application of doped polypyrrole/titanium dioxide nanotube composite material

A composite material, titanium dioxide technology, applied in the direction of secondary batteries, electrochemical generators, structural parts, etc., can solve the problems of demanding electrode materials, slow diffusion kinetics, complex and cumbersome preparation processes, etc., to achieve good conductivity, Good sodium storage activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

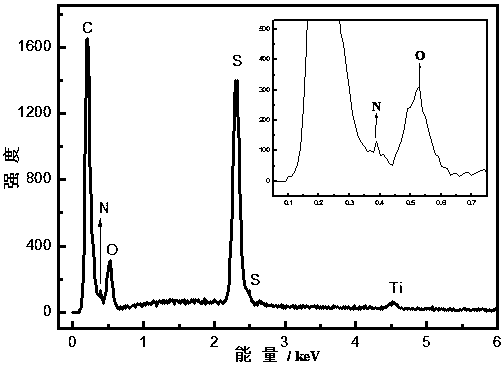

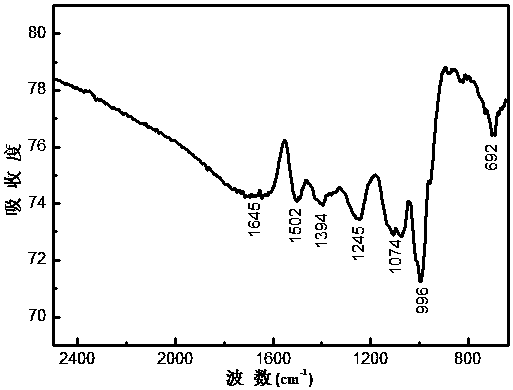

[0026] Doped polypyrrole / TiO described in this embodiment 2 The preparation method of nanotube composite material, concrete steps are as follows:

[0027] (1) Firstly, the anodic oxidation method is adopted, with the titanium sheet as the working electrode and the platinum electrode as the counter electrode, with the mass percentages of 0.5% NaF and 19.5% H 2 A mixture of O and 80% glycerol was used as the electrolyte, deposited at a constant voltage (30 V) for 2 h, and three-dimensional ordered TiO 2 nanotube arrays;

[0028] (2) Then in the three-electrode system, the three-dimensional ordered TiO prepared in step (1) 2 The nanotube array is used as the working electrode, the platinum sheet is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, and the aqueous solution containing sodium p-toluenesulfonate and pyrrole is used as the electrolyte, and the concentration of pyrrole in the electrolyte is 0.10mol / L, the concentrati...

Embodiment 2

[0032] Doped polypyrrole / TiO described in this embodiment 2 The preparation method of nanotube composite material, concrete steps are as follows:

[0033] (1) Firstly, the anodic oxidation method is adopted, with the titanium sheet as the working electrode and the platinum electrode as the counter electrode, with the mass percentages of 0.5% NaF and 19.5% H 2 A mixture of O and 80% glycerol was used as the electrolyte, deposited at a constant voltage (30 V) for 2 h, and three-dimensional ordered TiO 2 nanotube arrays;

[0034] (2) Then in the three-electrode system, the three-dimensional ordered TiO prepared in step (1) 2The nanotube array is used as the working electrode, the platinum sheet is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, and the aqueous solution containing sodium p-toluenesulfonate and pyrrole is used as the electrolyte, and the concentration of pyrrole in the electrolyte is 0.20mol / L, the concentratio...

Embodiment 3

[0037] Doped polypyrrole / TiO described in this embodiment 2 The preparation method of nanotube composite material, concrete steps are as follows:

[0038] (1) Firstly, the anodic oxidation method is adopted, with the titanium sheet as the working electrode and the platinum electrode as the counter electrode, and the mass percentages are 0.5%NaF and 19.5%H respectively. 2 The mixture of O and 80% glycerol was used as the electrolyte, deposited at constant voltage (30V) for 2h, and three-dimensional ordered TiO was prepared 2 nanotube arrays;

[0039] (2) Then in the three-electrode system, the three-dimensional ordered TiO prepared in step (1) 2 The nanotube array is used as the working electrode, the platinum sheet is used as the counter electrode, the saturated calomel electrode is used as the reference electrode, and the aqueous solution containing sodium p-toluenesulfonate and pyrrole is used as the electrolyte, and the concentration of pyrrole in the electrolyte is 0.15m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com