Vehicle double-screw power antenna lifting platform

A lifting platform, double screw technology, applied in the direction of antenna, antenna support/installation device suitable for movable objects, etc. Reduce assembly difficulty and transmission noise, improve stability and reliability, and improve transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

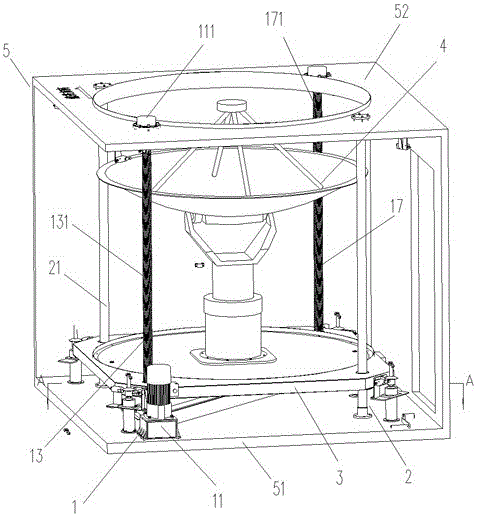

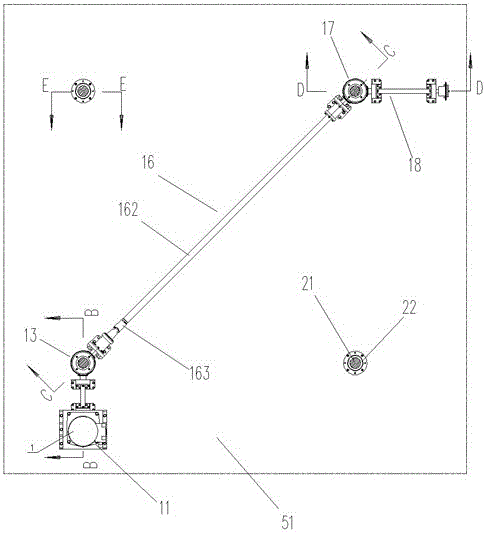

[0019] Such as Figure 1 to Figure 6 As shown, the present invention includes a transmission device 1, a guide device 2, a tray 3 and an antenna 4, the transmission device 1 is arranged on the northeast-southwest diagonal position of the compartment 5, and the guide device 2 is respectively arranged on the northwest-southeast direction of the compartment 5. corner position. The bottom of the antenna 4 is fixed on the tray 3, the tray 3 is located on the upper side of the compartment floor 51, and the four corners of the tray 3 are respectively connected with the transmission device 1 and the guide device 2.

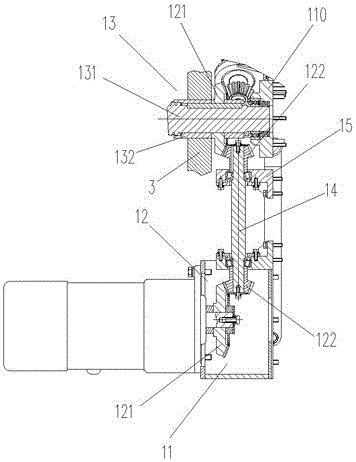

[0020] Such as image 3 As shown, the transmission device 1 includes a motor reduction transmission box 11, two sets of bevel gear transmission pairs 12, a driving screw nut pair 13, a transmission shaft 14, two bearing support seats 15, an intermediate connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com