Planetary metamorphic mobile mechanism

A technology of moving mechanism and planetary gear, which is applied in the direction of overhead line/cable equipment, etc., can solve the problems of long time to overcome obstacles, complicated operation process, and influence on operation stability, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

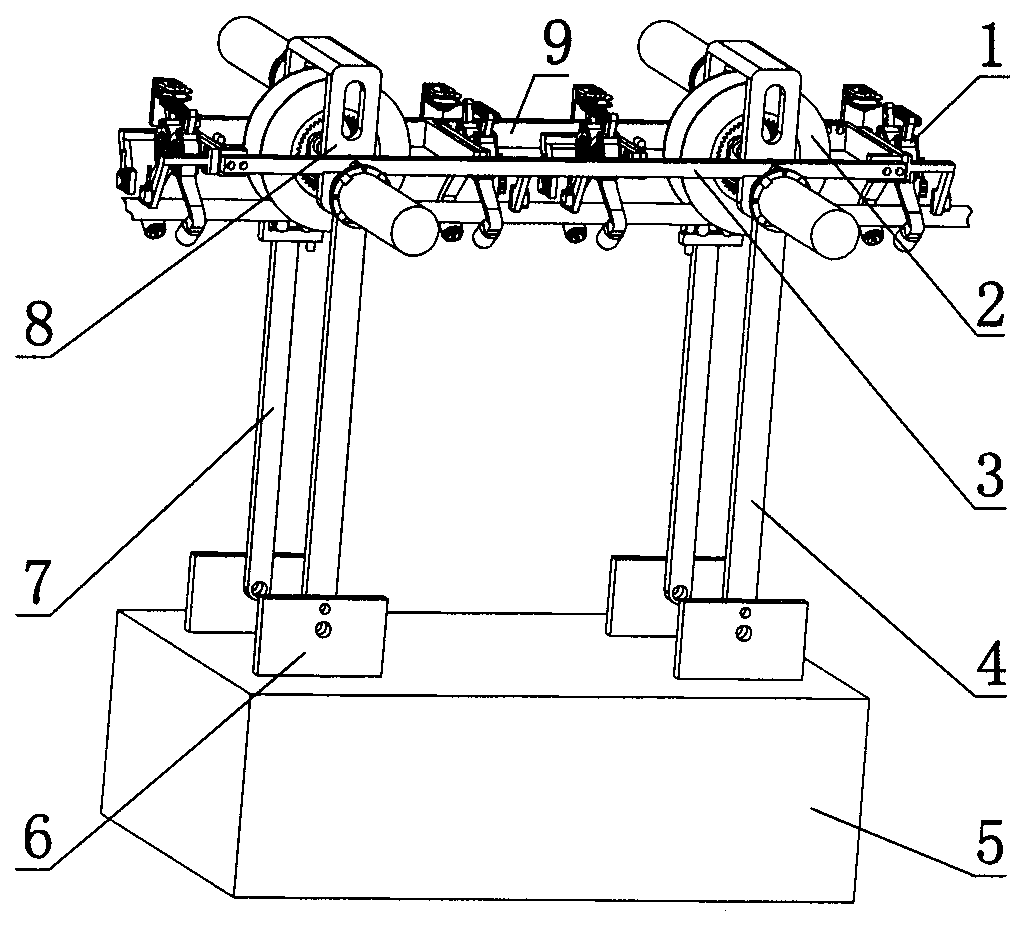

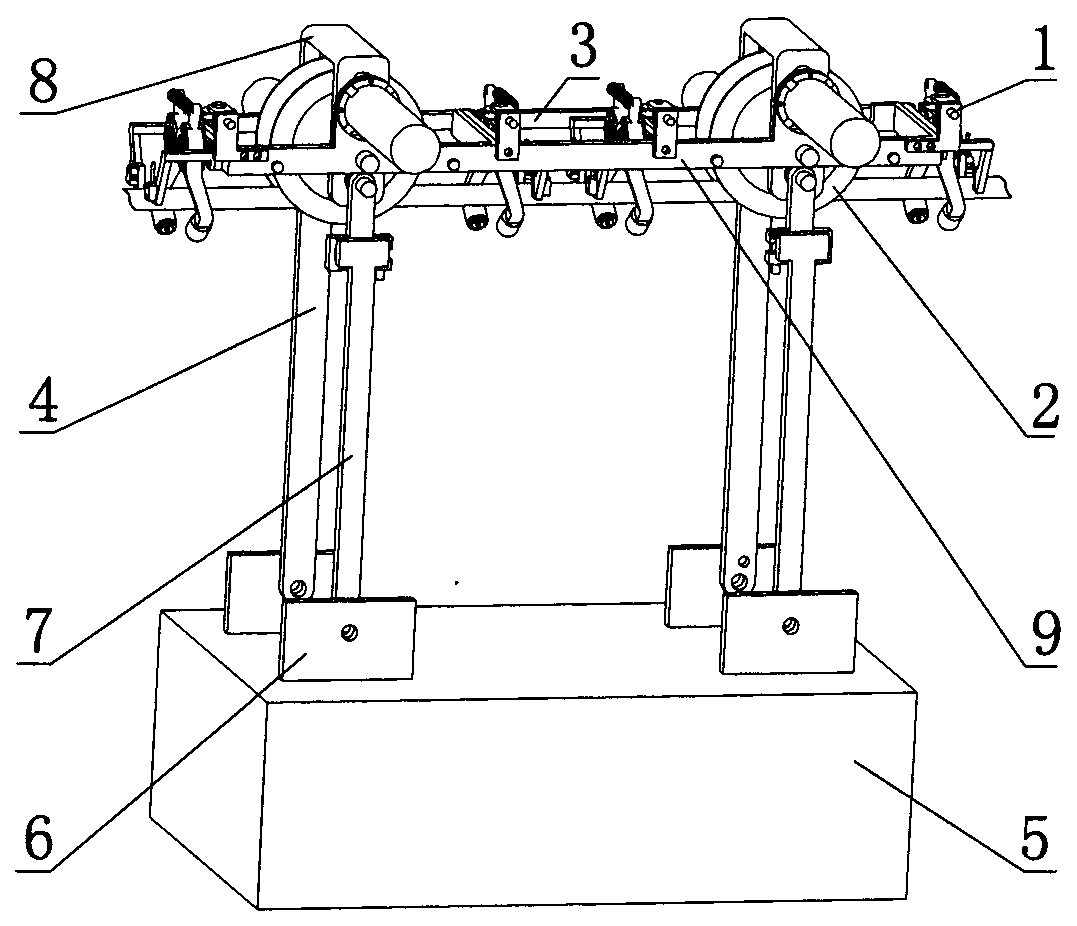

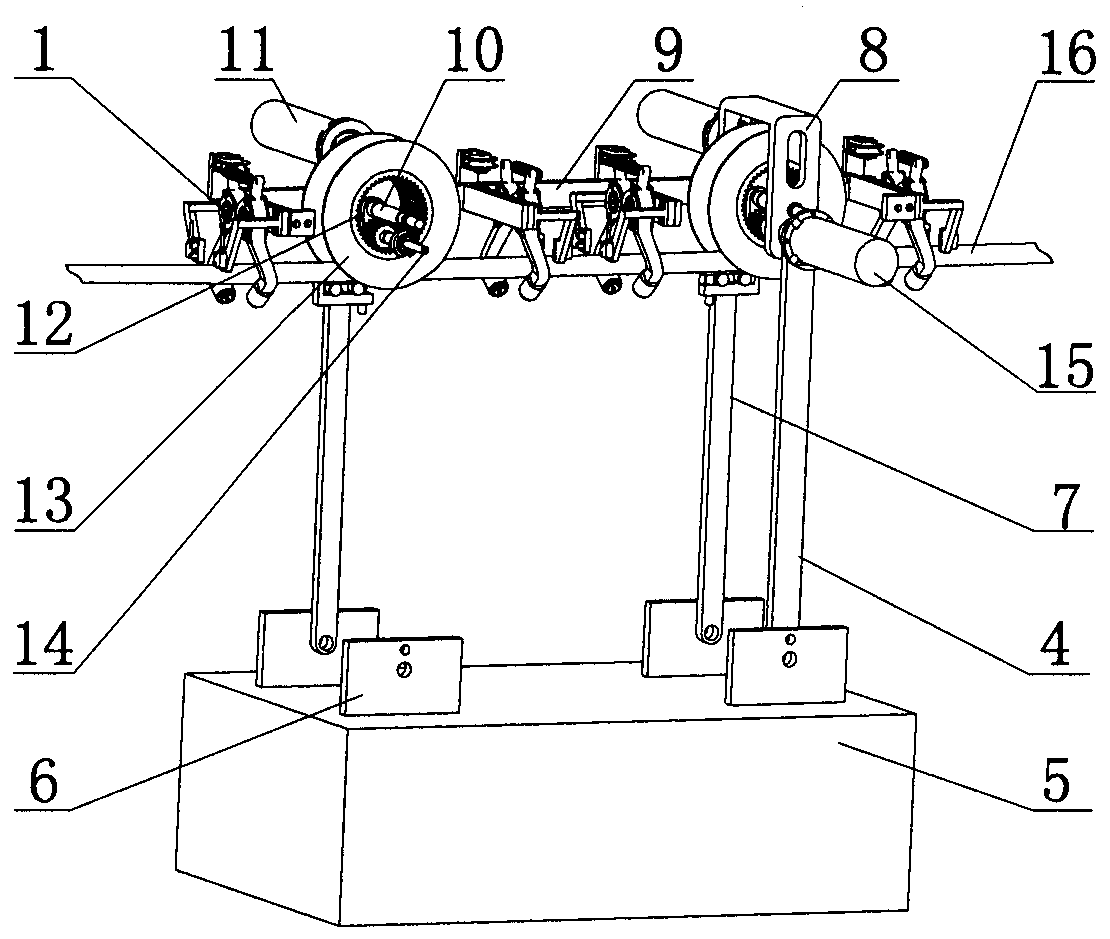

[0024] according to Figure 1-10 The specific structure of the present invention will be described in detail with specific embodiments. The planetary wheel metamorphic moving mechanism includes a linkage frame, and the components assembled on the linkage frame have the same structure and independently drive the front and rear traveling mechanisms, the front and rear clamping mechanisms 1 and the electric control box 5 connected together with the linkage frame. part. Wherein the linkage frame includes the linkage frame seat 9 and the linkage frame baffle plate 3 assembled together, and the linkage frame seat 9 and the linkage frame baffle plate 3 are connected and fixed by fasteners to facilitate installation. The front and rear clamping mechanism 1 adopts the basic structure of the front and rear clamping mechanism in "A Walking and Clamping Mechanism of a Line Patrol Robot with Fault Release Function" whose notification number is CN101471546B, while the front and rear travel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com