A magnetic field shielding method and device for machining a permanent magnet rotating shaft

A technology of mechanical processing and permanent magnet rotor, which is applied in the direction of electromechanical devices, shielding electromagnetic fields, manufacturing motor generators, etc., can solve the problems that are not used or not used to solve machining accuracy, so as to avoid adverse effects, improve precision and process the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

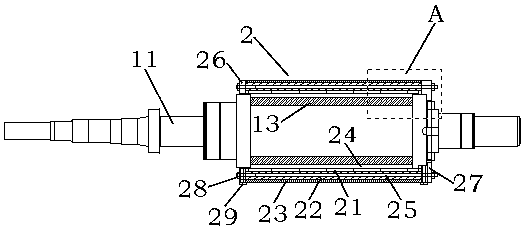

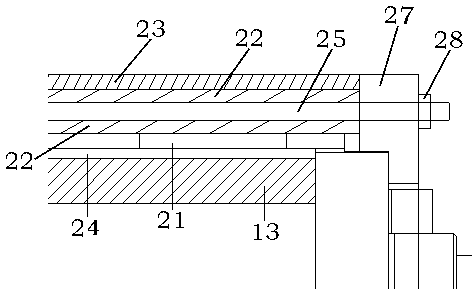

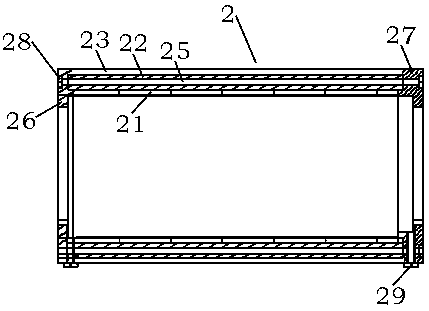

[0037] Such as figure 1 , image 3 and Figure 4 As shown, the magnetic field shielding device 2 is set on the permanent magnet rotor 1 to shield the magnetic field generated by the permanent magnets 12 in the permanent magnet rotor 1 . The permanent magnet rotor 1 includes: a permanent magnet rotating shaft 11 , a permanent magnet 12 and an iron core 13 . The magnetic field shielding device 2 includes: a shielding tube 23 , a silicon steel sheet layer 22 , a shielding layer protective cover 21 , a screw 25 , a left end cap 26 and a right end cap 27 . Wherein the left end cap 26 and the right end cap 27 are arranged on the axial direction of the permanent magnet rotating shaft 11, and the shielding cylinder 23, the silicon steel sheet layer 22 and the shielding layer protective sleeve 21 are arranged on the circumferential direction of the permanent magnet rotating shaft 11 from outside to inside direction.

[0038] Such as figure 1 , figure 2 and image 3 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com