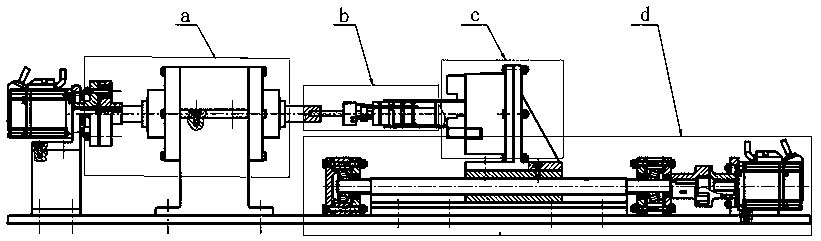

Adjustable Magnetic Field and Adaptive Aperture Magnetic Abrasive Finishing Device and Method

A magnetic grinding tool and finishing technology, which is applied in the direction of grinding drive device, metal processing equipment, grinding workpiece support, etc., can solve the problems of non-adjustable magnetic field strength, high heat generation, and huge device structure, etc. Achieve the effect of increasing complexity, improving uniformity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

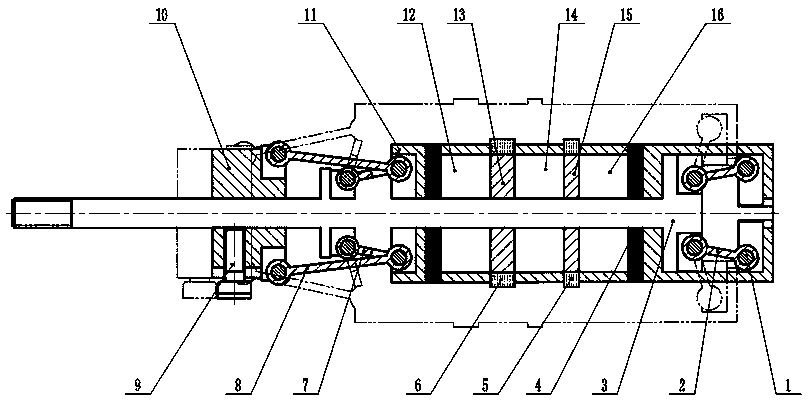

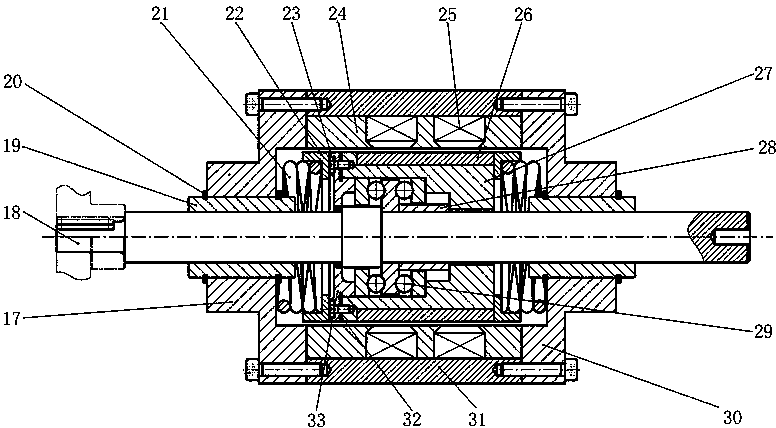

Method used

Image

Examples

Embodiment 1

[0049] A magnetic abrasive tool finishing device and method with an adjustable magnetic field and an adaptive aperture, the processing parameters of which are as described in Table 1:

[0050] Table 1 Example 1 Processing parameters

[0051] parameter Magnetic pole speed / (r / min) SiC particle size / # Fe: SiC Workpiece material Workpiece inner diameter / mm Raw roughness of workpiece inner surface Ra / μm Processing time / min value 300 240 13:7 6061 aluminum alloy 33 0.772 15

[0052] Its specific steps:

[0053] 1. Adsorb the magnetic abrasive on the periphery of the soft iron.

[0054] 2. Clamp the tubular part to be processed on the three-jaw chuck, and then extend the finishing processing execution part into the interior of the tubular part.

[0055] 3. Start the motor and adjust its speed at 300r / min.

[0056] 4. After the rotation speed of the motor and the amplitude and frequency of the vibrating device are stabilized, start the feedi...

Embodiment 2

[0060] An adjustable magnetic field and self-adaptive aperture magnetic grinding tool finishing processing device and method, the processing parameters are as described in Table 2:

[0061] Table 2 Example 1 processing parameters

[0062] parameter Magnetic pole speed / (r / min) Abrasive size / # Fe: SiC Workpiece material Workpiece inner diameter / mm Raw roughness of workpiece inner surface Ra / μm Processing time / min value 250 240 7:3 6061 aluminum alloy 33 0.769 10

[0063] Its specific steps:

[0064] 1. Adsorb the magnetic abrasive on the periphery of the soft iron.

[0065] 2. Clamp the tubular part to be processed on the three-jaw chuck, and then extend the finishing processing execution part into the interior of the tubular part.

[0066] 3. Start the motor and adjust its speed at 250r / min.

[0067] 4. After the rotation speed of the motor and the amplitude and frequency of the vibrating device are stabilized, start the feeding part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com