A Surface Acoustic Wave Resonator with Precisely Weighted Metal Lattice of Reflective Grid

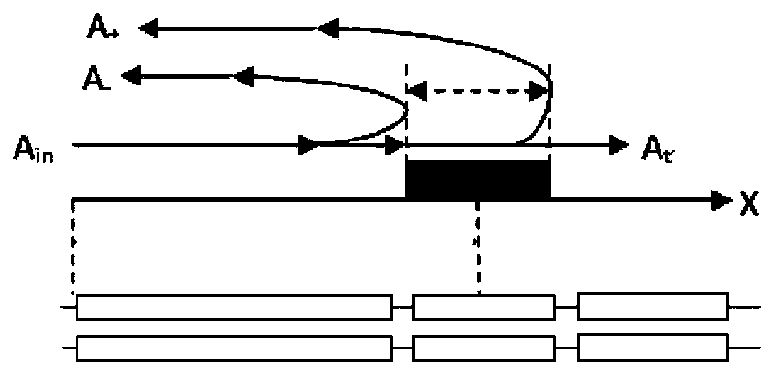

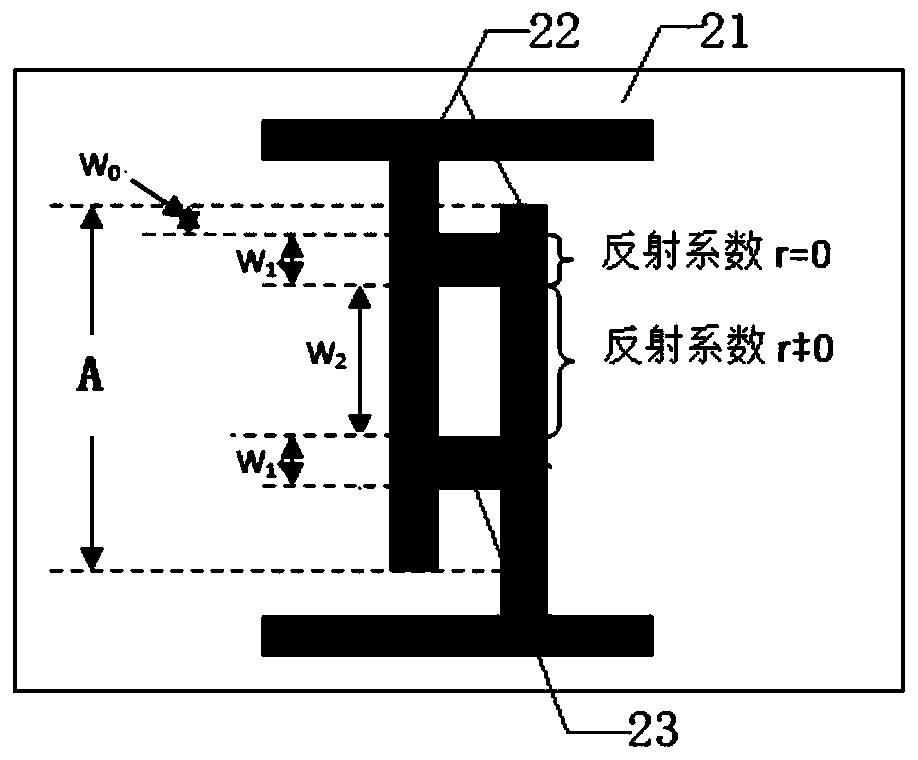

A metal lattice, surface acoustic wave technology, applied in impedance networks, electrical components, etc., can solve the problems of large acoustic wave diffraction and small aperture of reflection gratings, and achieve the effects of sidelobe suppression, accurate weighting, and improved frequency response performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

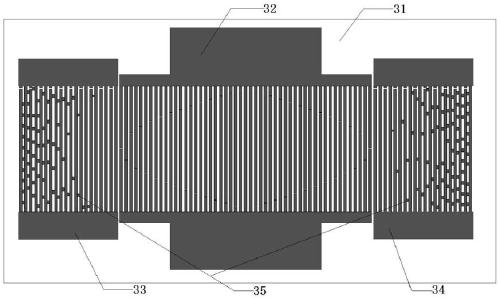

[0055] The substrate adopts ST-X quartz. The metal lattice 35 of the reflective grid is weighted in two ways: Hamming function weighting and precise weighting. Specifically, the SAW resonator structure after the reflective grating is weighted by Hamming function lattice weighting and precise weighting is obtained through software simulation to obtain the S11 parameters of the SAW resonator, as shown in Figure 6 shown. With precise weighting, compared with the SAW resonator S11 in which the reflective grid metal lattice 35 is weighted by the Hamming function, the side peaks are reduced from 0.02517 to about 0.0034.

Embodiment approach 2

[0057] The substrate is made of ST quartz; the metal lattice 35 of the reflective grid is weighted by arccosine function weighting and precise weighting. Specifically, the SAW resonator structure is weighted by two methods of arccosine function lattice weighting and precise weighting, and the S11 parameter of the SAW resonator is obtained through software simulation, as shown in Figure 7 shown. Using precise weighting, compared with the parameters of the SAW resonator S11 whose reflective grid metal lattice 35 is weighted by an arccosine function, the side peaks are reduced from 0.0225 to about 0.0125.

Embodiment approach 3

[0059] The substrate is made of ST quartz; the metal lattice 35 of the reflective grid is weighted by Kaiser (beta=3.2) function and precise weighting. Specifically, the SAW resonator structure is weighted by Kaiser function lattice weighting and precise weighting, and the S11 parameters of the SAW resonator are obtained through software simulation, such as Figure 8 shown. Using precise weighting, compared with the SAW resonator S11 parameter weighted by the Kaiser (beta=3.2) function of the reflective grid metal lattice 35, the side peaks are reduced from 0.0184 to about 0.0076.

[0060] Through the comparison of the above three embodiments, it can be seen that on the basis of the metal lattice function lattice on the reflection grid, the precise weighting of the metal points can eliminate the serious sound wave diffraction caused by the small reflection aperture, which affects the reflection accuracy. By optimizing the weighting method, the side lobe is further suppressed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com