Ceiling unit and elevator car with ceiling unit

A ceiling and elevator technology, which is applied to elevators, transportation and packaging in buildings, can solve the problems of inability to reduce the quality, and achieve the effect of reducing the number of parts and reducing the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

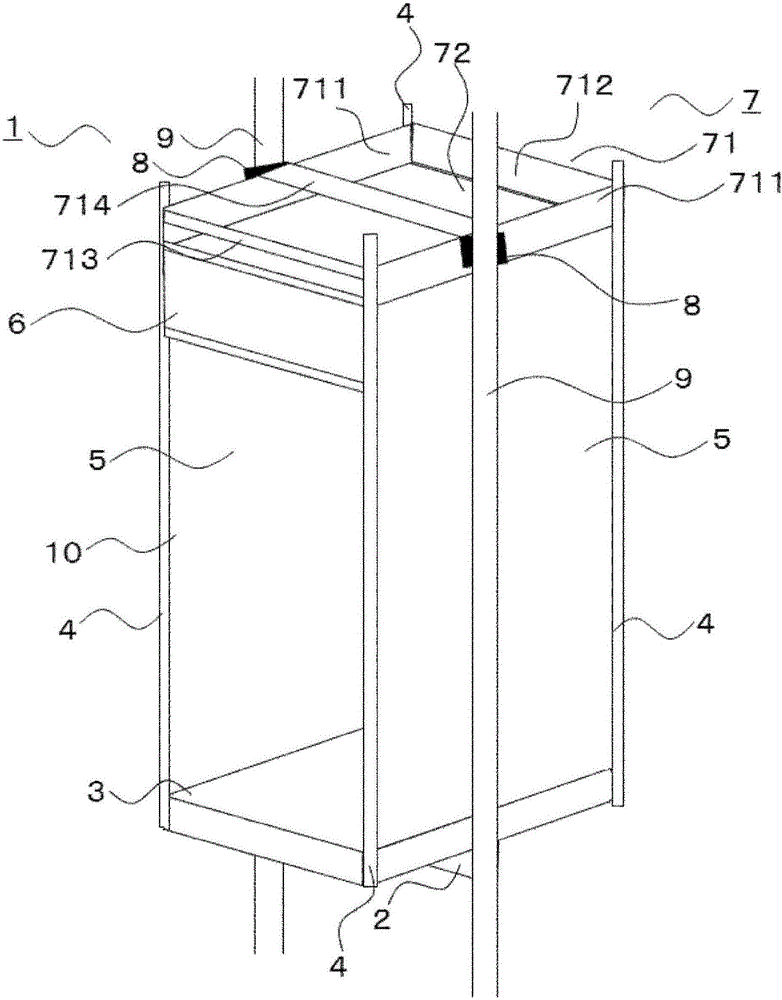

[0026] figure 1 It is a perspective view showing the elevator car according to Embodiment 1 of the present invention. exist figure 1 Among them, the car 1 is composed of a car room, a ceiling unit 7 forming the ceiling part of the car room, and guide shoes 8 provided on the ceiling unit 7, wherein the car room has: a lower frame 2, which has an emergency Stopping parts; car floor 3, which is provided on the lower frame 2; columns 4, which are erected at the four corners of the car floor 3; a pair of side walls 5, which form the sides of the car; front walls (not shown), which are arranged opposite to the entrance 10; car doors (not shown), which open and close the entrance 10;

[0027] When the car 1 ascends and descends in the hoistway, the car 1 is guided by guide rails 9 provided in the hoistway by means of guide shoes 8 .

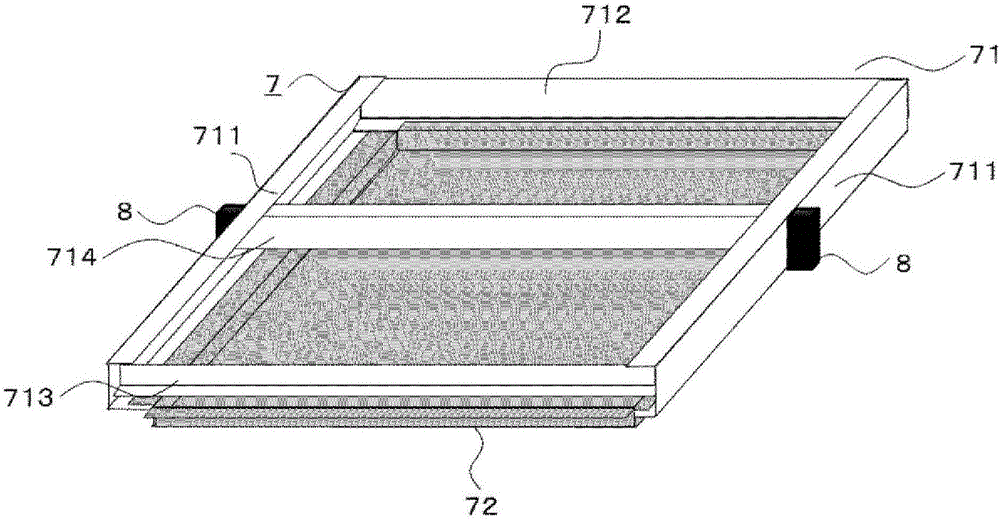

[0028] figure 2 It is a perspective view which shows the ceiling unit 7 which concerns on Embodiment 1 of this invention. exist figure 2 Among ...

Embodiment approach 2

[0074] In Embodiment 1, the horizontal portion 713a of the front beam 713 is positioned higher than the horizontal portion 711a of the side beam 711 and the horizontal portion 712a of the rear beam 712, but may be provided at the same height. Figure 11 It is a perspective view showing the upper frame 71 of this embodiment. Such as Figure 11 As shown, the horizontal portion 713a of the front beam 713 is formed by bending toward the rear side of the car 1 , and the horizontal portion 713a has a screw hole 12 for connecting with the front horizontal portion 723b of the ceiling 72 .

[0075]The lower horizontal portion 711a of the side beam 711 retains the front-rear dimension of the horizontal portion 712a of the rear beam 712 from the rear end surface of the steel material, and retains the front-rear dimension of the horizontal portion 713a of the front beam 713 from the front end surface of the steel material. The amount is formed by bending the central part. Therefore, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com