Weir module for a pyrometallurgical furnace

A technology for smelting furnaces and panels, applied in the field of interchangeable weir modules, can solve the problems that hinder the separation of weirs and furnaces, and achieve the effect of simple and fast practicality and supply processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

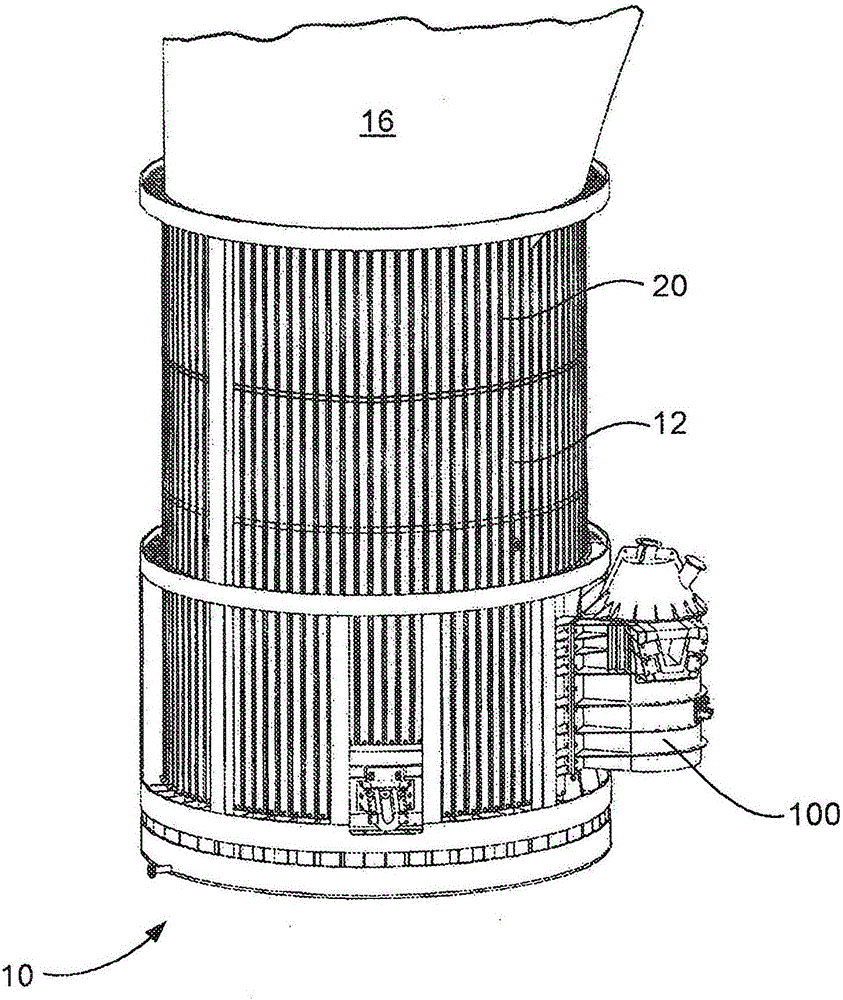

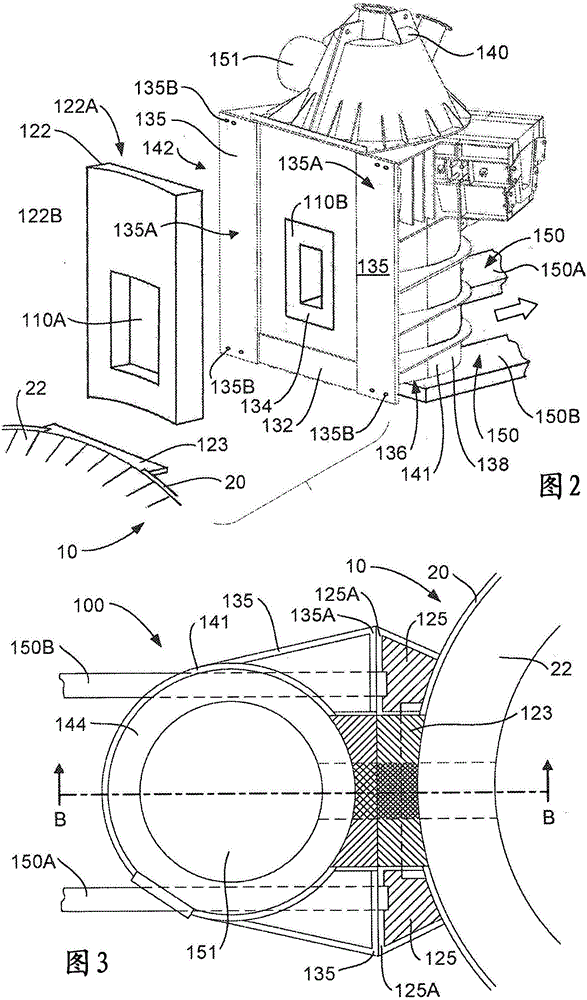

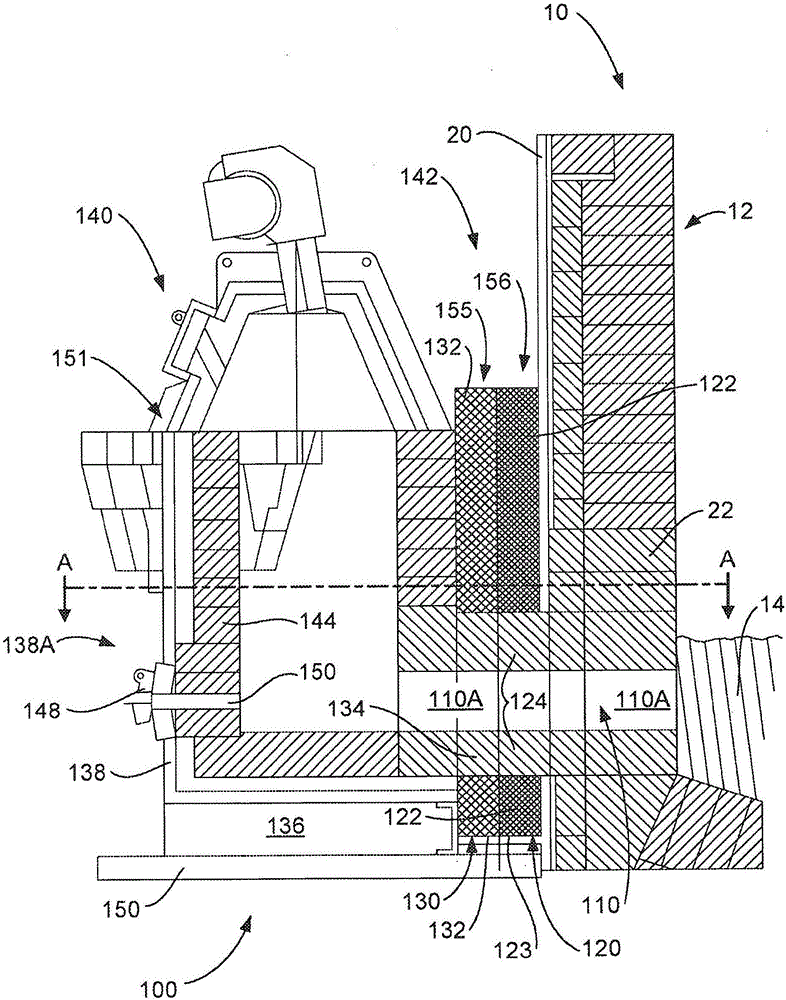

[0037] figure 1 A top submerged lance (TSL) furnace 10 comprising a weir module 100 according to the invention is shown. It should be understood that the TSL furnace 10 is shown and described in the following detailed description for purposes of illustration only. A weir module 100 of similar construction may equally be attached to other types of smelting furnaces.

[0038] first reference figure 1 , showing a TSL reactor or furnace 10 suitable for carrying out (pyro)smelting operations, spraying using a top-blown submerged lance (TSL) with a TSL lance, the TSL reactor or furnace having a Weir module 100 . A cut-away section of the furnace 10 is also shown in Figure 4 middle. Furnace 10 also has a function for containing molten bath 14 (see Figure 4 ), the molten bath contains or has a top layer of slag. The base portion 12 and roof 16 of the furnace 10 typically have a steel shell 20 internally lined with a suitable refractory material 22 ( Figure 4 ).

[0039] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com