OLED special-shaped sealing glue reinforcing machine and sealing glue reinforcing method

A reinforcing machine and glue sealing technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of increasing equipment cost, dispensing quality is affected by glue gravity, unfavorable full use of reinforcing machine, etc., to achieve The effect of precise adjustment and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

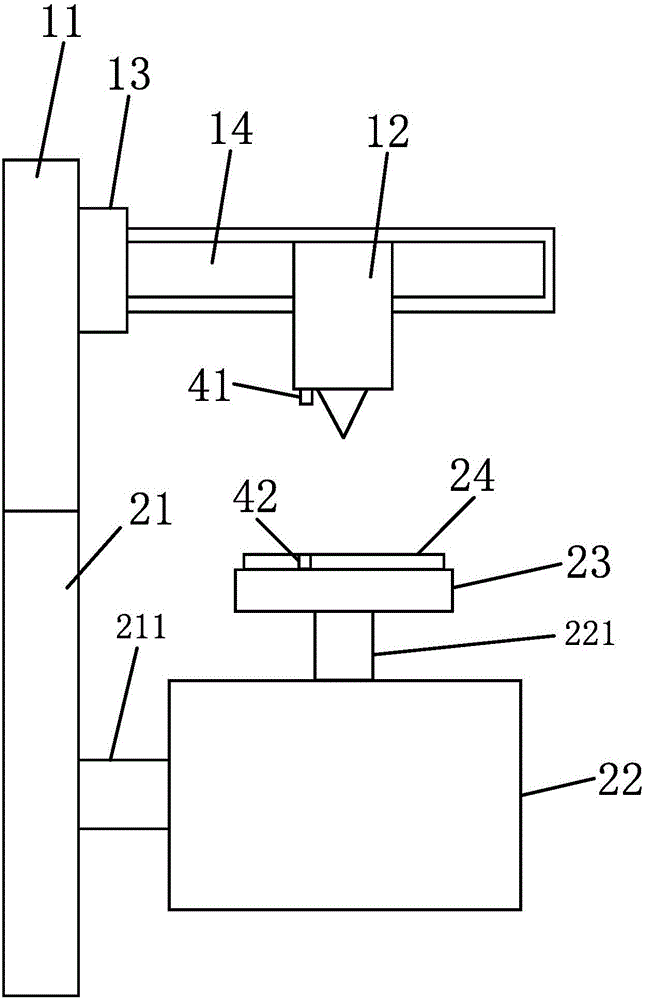

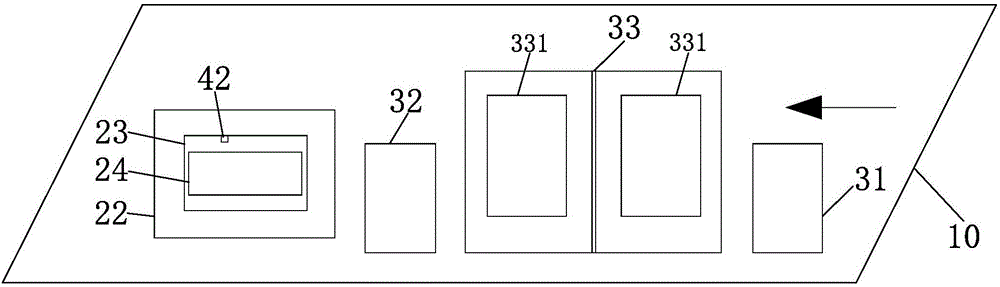

[0039] Such as figure 1 and figure 2 As shown, the present invention provides a special-shaped OLED sealing and reinforcing machine, including a workbench 10, a glue dispensing device and a substrate fixing device. The dispensing device is located on the workbench 10; the dispensing device includes a vertical first guide rail 11 and a dispensing nozzle 12 for vertically downward spraying dispensing, and the dispensing nozzle 12 is vertically slidably connected to the first guide rail 11. The substrate fixing device is located at the position below the corresponding dispensing device on the workbench 10. The substrate fixing device includes a vertically arranged support frame 21, a first carrier 22 that is rotatably connected to one side of the support frame 21, and a first carrier that is rotatably connected to the first carrier. 22 of the second carrier 23 .

[0040] In the above embodiment, the rotation direction of the first stage 22 and the rotation direction of the sec...

specific Embodiment approach

[0042] As a specific embodiment of the present invention, the dispensing device also includes a second guide rail 13 and a third guide rail 14 perpendicular to each other in a horizontal plane; the second guide rail 13 is vertically slidably connected to the first guide rail 11; the third guide rail 14 is horizontally slidable connected to the second rail 13; the dispensing nozzle 12 is slidingly connected to the third rail 14. Through the cooperation of the first guide rail 11 , the second guide rail 13 and the third guide rail 14 , the flexible movement of the dispensing nozzle 12 in the three-dimensional direction is realized to precisely adjust the alignment of the dispensing nozzle 12 and the side of the substrate 24 .

[0043] As a specific embodiment of the present invention, the special-shaped sealing and reinforcing machine provided by the present invention also includes a feeding device. Such as image 3As shown, the feeding device includes a handling assembly and a...

Embodiment 2

[0046] A method for reinforcing OLED special-shaped sealing glue, comprising the following steps:

[0047] S10, inputting the horizontal substrate 24;

[0048] S20, adjusting the substrate 24 to a vertical state;

[0049] S30, adjusting the dispensing nozzle 12 to align with the side of the substrate 24 in the vertical state;

[0050] S40, rotate the substrate 24, and the dispensing nozzle 12 sequentially dispenses glue to several sides of the substrate 24;

[0051] Wherein, adjusting the dispensing nozzle 12 to align with the side of the substrate 24 in the vertical state includes.

[0052] In this embodiment, the substrate 24 to be dispensed is adjusted from a horizontal state to a vertical state, so that the side of the substrate 24 is horizontally aligned to the bottom of the dispensing nozzle 12, and the side of the dispensing nozzle 12 and the substrate 24 are aligned. In the case of continuous adjustment of the relative displacement in the vertical direction, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com