Welding fixture for interchangeable roof frame assembly

A welding fixture and assembly technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of wasting time, affecting product quality stability, poor positioning accuracy, etc., and achieve accurate positioning and tooling deformation Quick and save storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

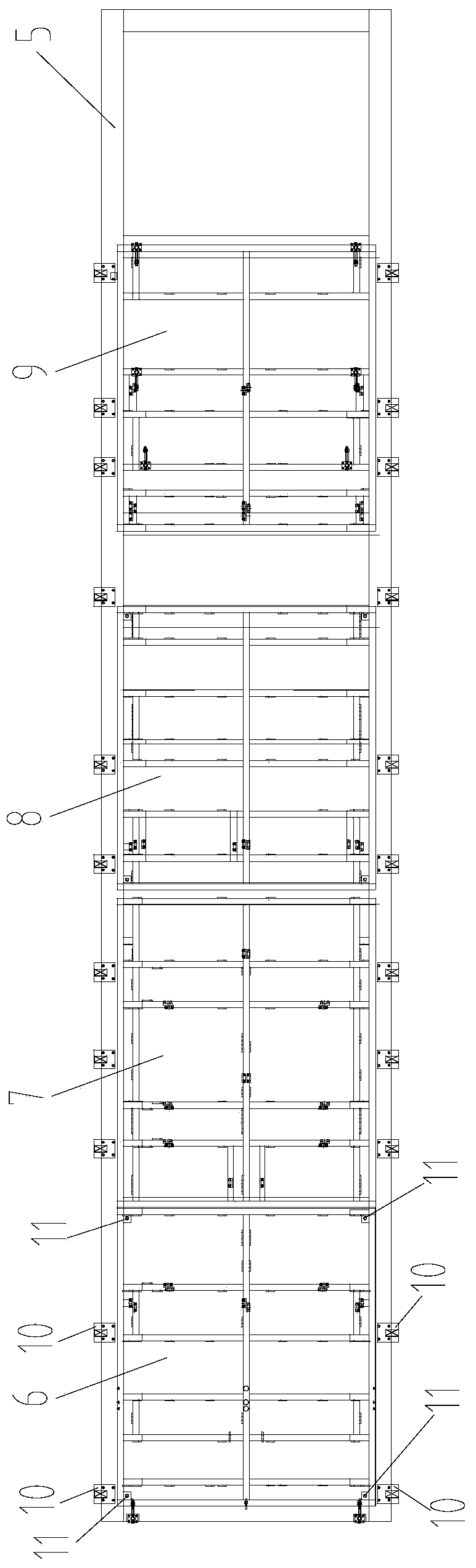

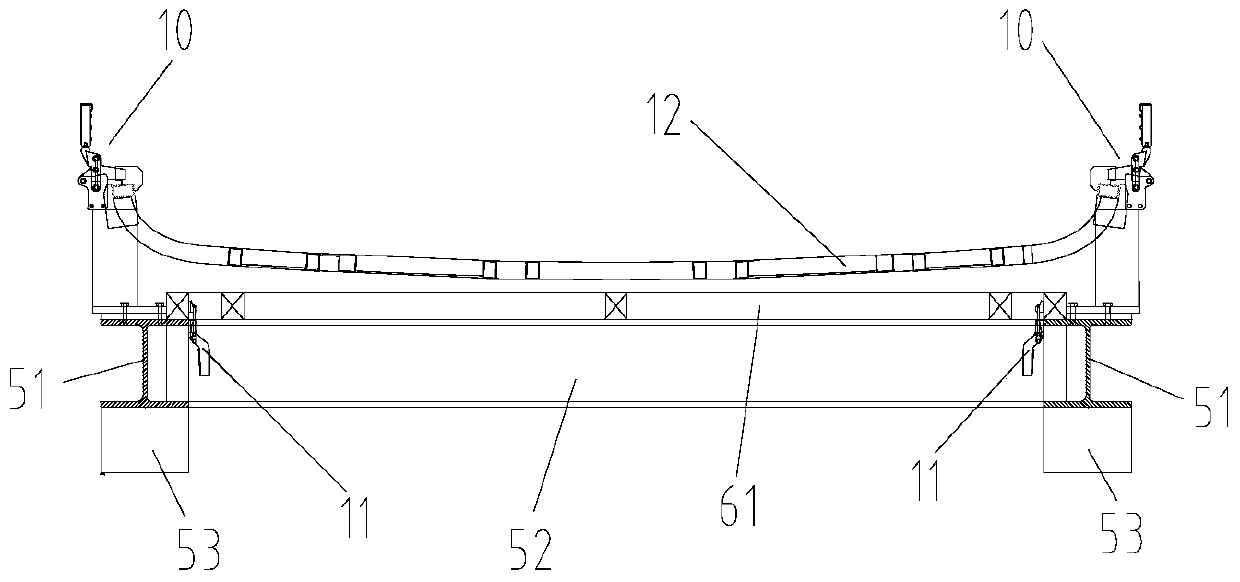

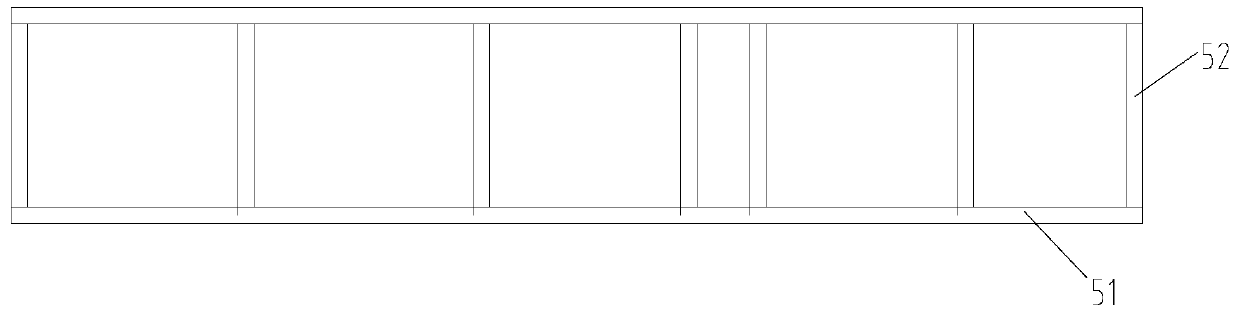

[0035] An interchangeable roof frame assembly welding fixture, such as Figure 1~3 As shown, it includes a universal chassis 5 and a tooling assembly composed of a first tooling unit 6 , a second tooling unit 7 , a third tooling unit 8 and a fourth tooling unit 9 fixed on the universal chassis 5 in sequence. The general underframe 5 comprises a frame formed by two parallel beams 51 and several parallel longitudinal beams 52 connected to the two beams 51 at both ends. The bottom of the universal underframe 5 is provided with 12 columns, the crossbeams 51 and the longitudinal beams 52 H-shaped steel with a cross-section of 200mm*200mm*10mm is adopted, and the general underframe 5 is formed by tailor welding. The roof frame assembly 12 is placed on the tooling assembly, and each tooling unit includes a frame formed by connecting several horizontal square tubes and vertical square tubes, wherein the square tubes are high-strength tubes of 60mm*50mm*4mm, such as Figure 6-9 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com