Welding jig for aluminum compartment door frame skeleton of passenger car

A welding jig, aluminum bus technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of production efficiency, shortening production cycle and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

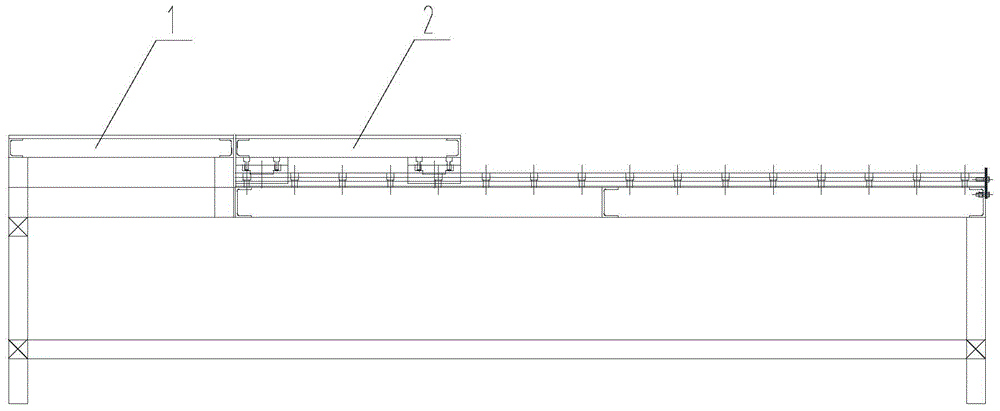

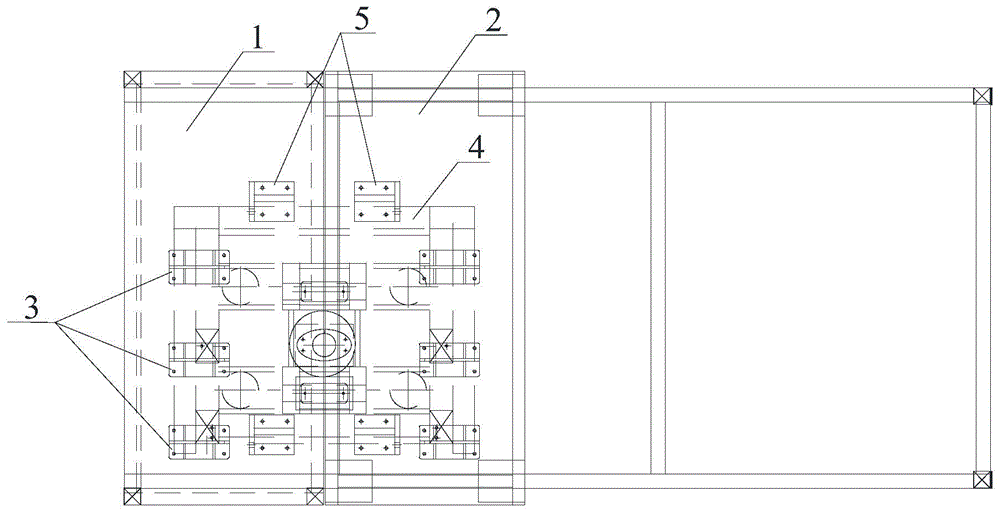

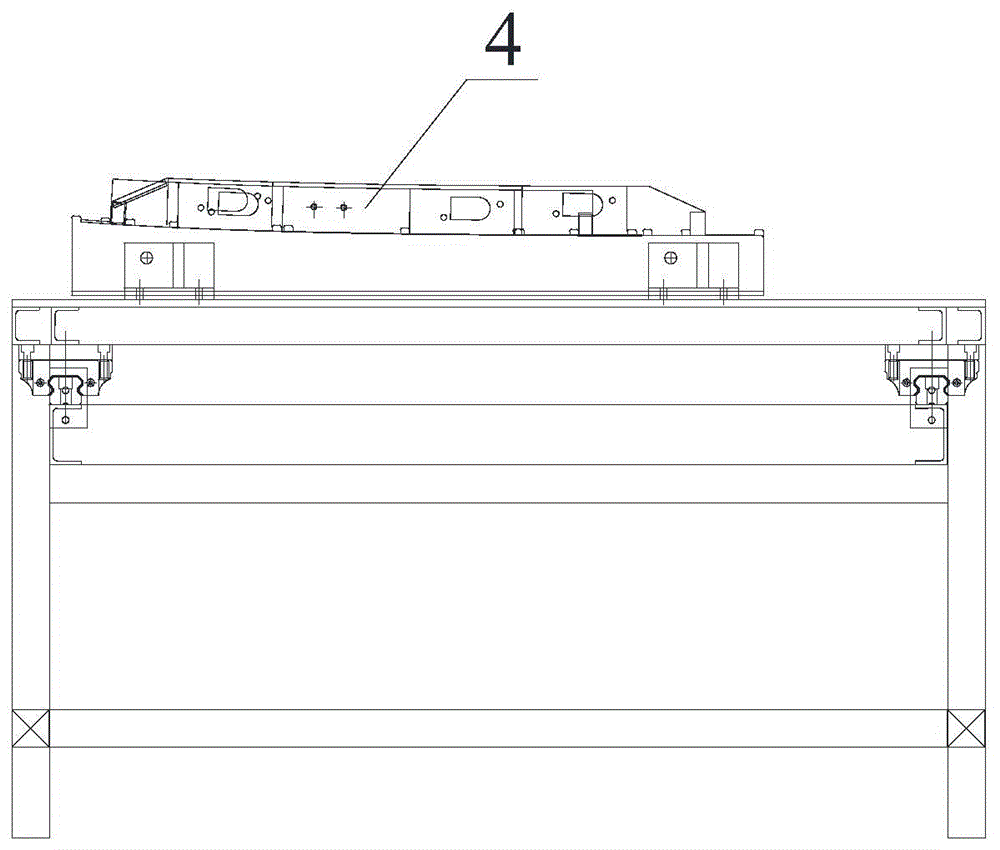

[0036] Such as Figure 1-Figure 4 As shown, a welding fixture for the aluminum warehouse door frame of a passenger car includes a fixed workbench 1, a movable workbench 2 and a positioning assembly, the fixed workbench 1 includes a linear slide rail 102, and the movable workbench 2 The slide rail 102 is connected with the fixed workbench 1, and the positioning components are provided in two groups, which are symmetrically arranged on the fixed workbench 1 and the movable workbench 2 respectively. The position of the movable workbench 2 is set according to the width of the frame of the aluminum warehouse door frame to be welded. The movable workbench 2 slides to the set position on the linear slide rail 102, and the aluminum alloy is fixed by the positioning components on the fixed workbench 1 and the movable workbench 2. Carry out welding operation after the warehouse door frame skeleton 4.

Embodiment 2

[0038] refer to Figure 1-4 As shown, this embodiment provides a welding fixture for the frame of the aluminum warehouse door frame of a passenger car. The difference from Embodiment 1 is that, as Figure 4-Figure 6 As shown, the fixed workbench 1 of this embodiment also includes a bracket, a fixed panel 101 and a limit block 113, the fixed panel 101 is connected to the linear slide rail 102, and is arranged on the support at the same time, and the limit block 113 is arranged at the end of the linear slide rail 102 , and the positioning assembly is movably arranged on the fixed panel 101 . The support includes a first longitudinal beam 103, a second longitudinal beam 104, a first beam 105, a first column 106, a second beam 107, a second column 108, a third column 109, a third beam 110, and a fourth beam 111 and the fifth crossbeam 112, each crossbeam, column and longitudinal beam are welded by carbon dioxide gas shielded welding, the welding is firm, there is no false welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com