Alternate Nail Feeding Device and Operation Method of Case Riveting Machine

An operation method and technology of a riveting machine, which are applied to the field of discharging devices on a casing riveting machine, can solve the problems of prolonging the time required for nail feeding, low production efficiency, long time-consuming manual assembly, etc., so as to shorten the delivery cycle and improve the Efficiency, effect of shortening waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

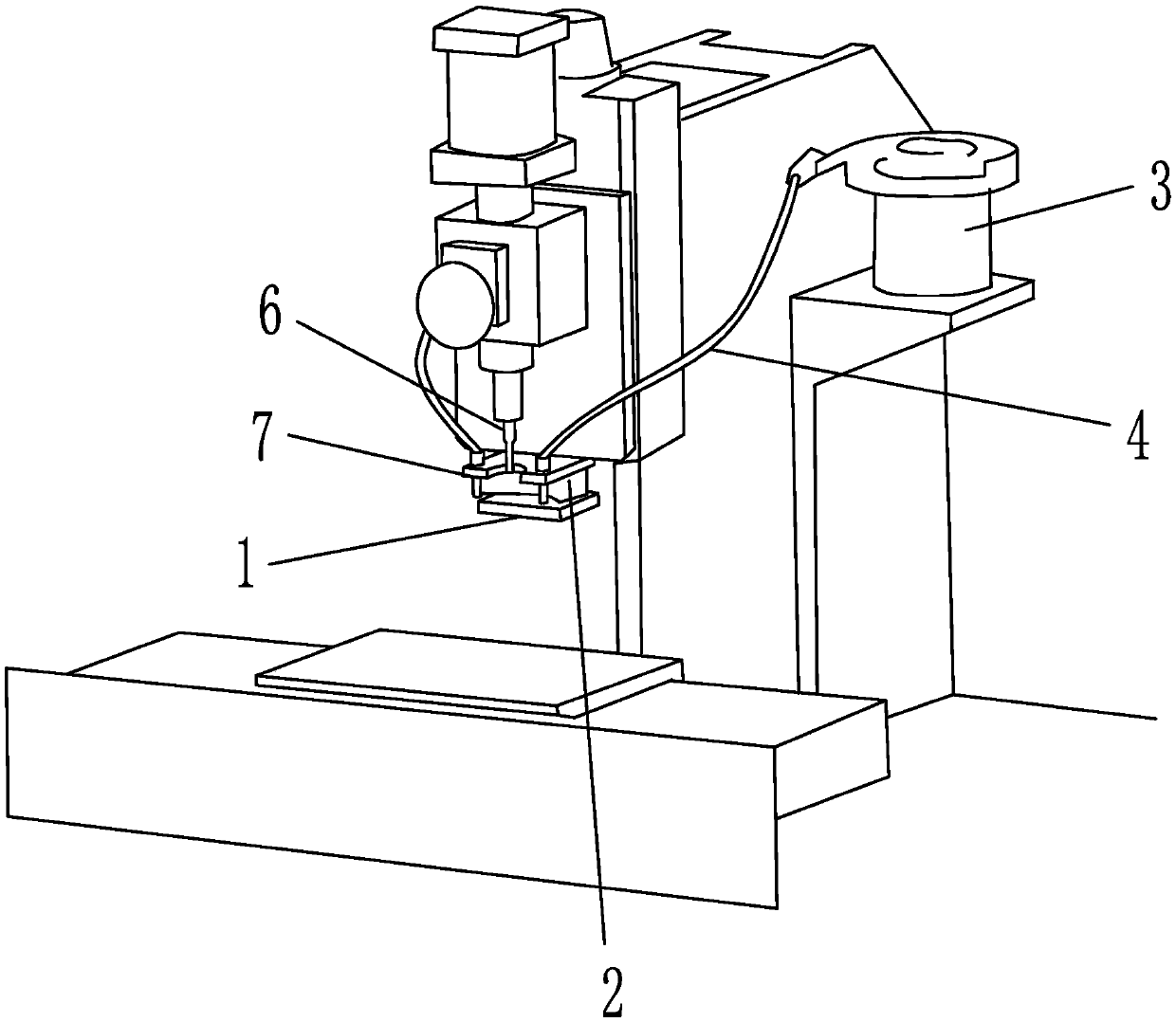

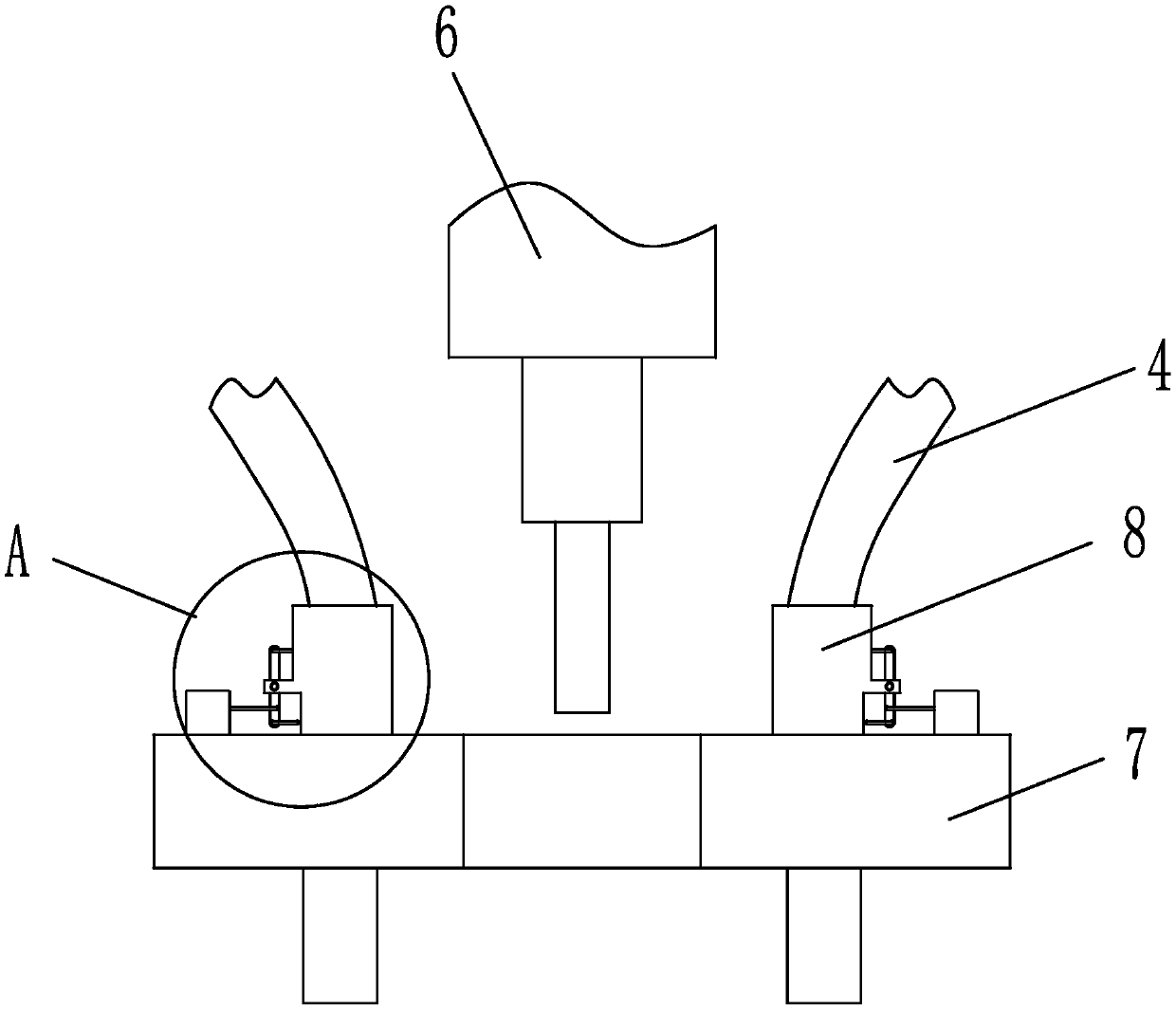

[0022] Embodiment 1: as figure 1 As shown, an alternate nail feeding device for a casing press riveting machine includes a vibrating discharger and a nailing mechanism 3. The nailing mechanism includes a positioning plate 7 and a supporting plate 1 located below the positioning plate. Between the positioning plate and the supporting plate An adjustment cylinder is provided, and a positioning sleeve 8 is installed on the positioning plate 7. Two vibrating discharge machines 3 are arranged on the side of the frame. The exit of the vibrating discharge machine is connected with a nail feeding tube 4, and the nail feeding tube is far away from the vibration discharging material. One end of the machine is connected with the positioning sleeve. Such as figure 2 ,5 As shown, the side of the positioning sleeve is provided with a nail cutting mechanism for alternately cutting off the flow of the positioning sleeve. The nail cutting mechanism includes a driving cylinder 9, an alternate...

Embodiment 2

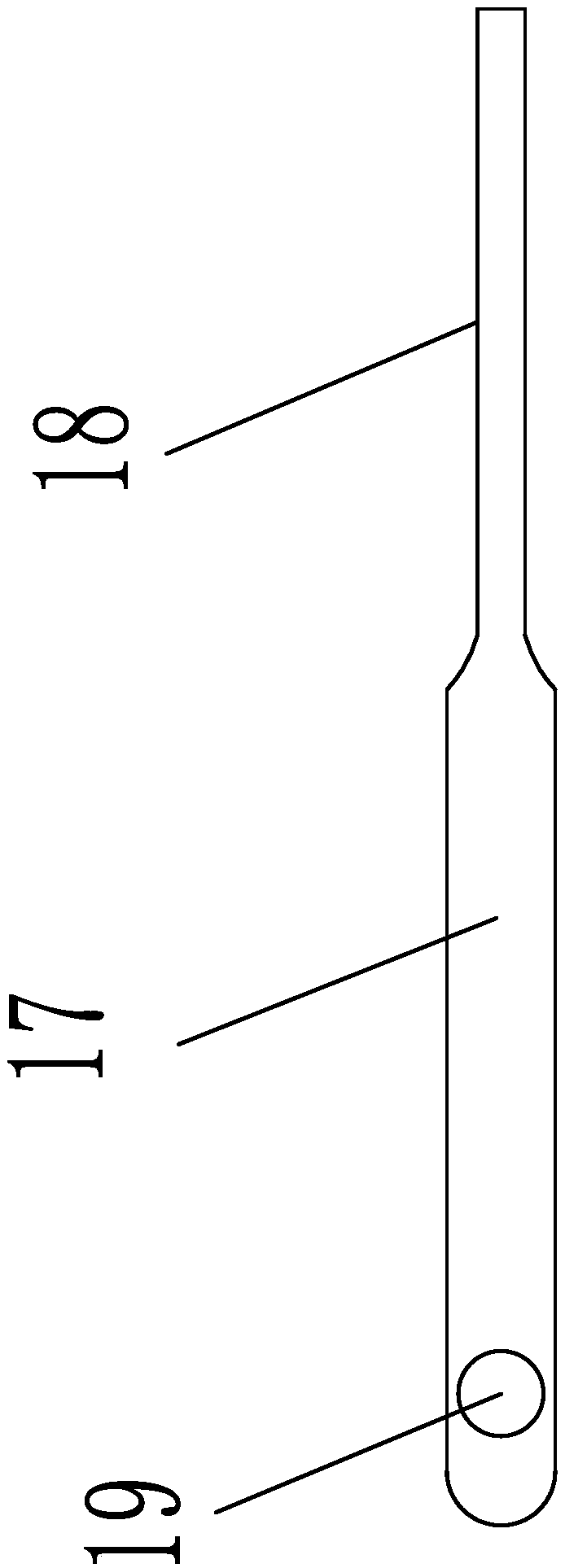

[0024] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 8 As shown, an air guide tube is set on the outer side of the nail delivery tube, and an air guide channel is provided between the air guide tube and the nail delivery tube. The positioning sleeve is connected to the nail input hole. The connecting seat is provided with a first annular groove for fixing the nail input tube and a second annular groove for fixing the air guide tube. Air cavity 26, one end of the air guiding cavity communicates with the air guiding channel, and the other end communicates with the nail input hole 27. The outer side of the nail delivery tube is covered with an air guide tube 21, so that an air guide channel 22 is formed between the air guide tube and the nail delivery tube. Both the air guide tube and the nail delivery tube are connected to the positioning sleeve through the connecting seat, and the screws in the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com