Lathe security protection system

A technology of safety protection and safety protection device, which is applied in the field of lathe safety protection system, can solve the problems of danger, involvement, and no way to really protect the safety of personnel, and achieve the effect of good safety protection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Specific embodiment:

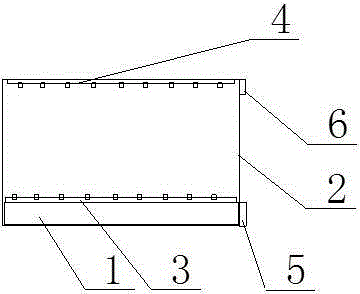

[0018] Combine figure 1 The safety protection system of a lathe shown includes a lathe 1 and a safety protection device. The safety protection device includes a protection frame 2, an infrared transmitter 3 arranged on the lathe 1 and an infrared sensor 4 arranged on the protection frame 2. The frame 2 is set on the lathe 1, and the infrared transmitter 3 is located directly under the infrared sensor 4. The protective frame 2 is also provided with a protective device controller 5 and an alarm 6, and the infrared transmitter 3 and the infrared sensor 4 are controlled by the protective device The alarm device 5 is controlled, and the alarm device 6 is connected with the infrared sensor 4.

[0019] In this embodiment, the infrared light beam emitted by the infrared transmitter 3 corresponds to the infrared light beam sensing element of the infrared sensor 4 one to one.

[0020] In this embodiment, the infrared beams are emitted in a staggered manner.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com