Control method of control system for feeding device of injection molding machine

A technology of a feeding device and a control system, which is applied in the control field of the control system of the feeding device of an injection molding machine, can solve the problems of low feeding efficiency, high feeding work, and small feeding labor, so as to save manpower, reduce consumption, and achieve quick results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

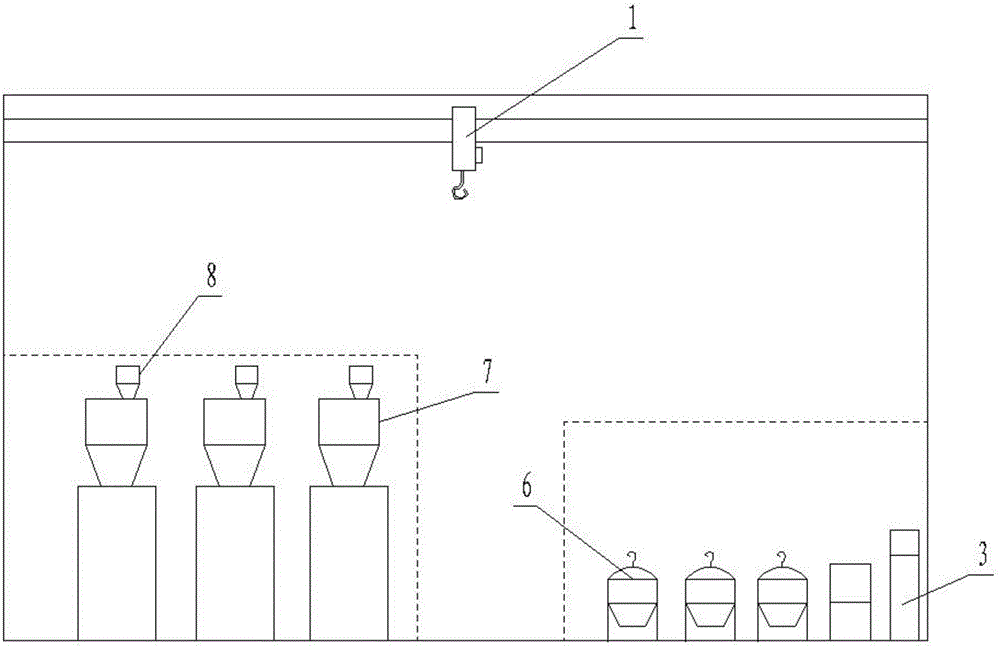

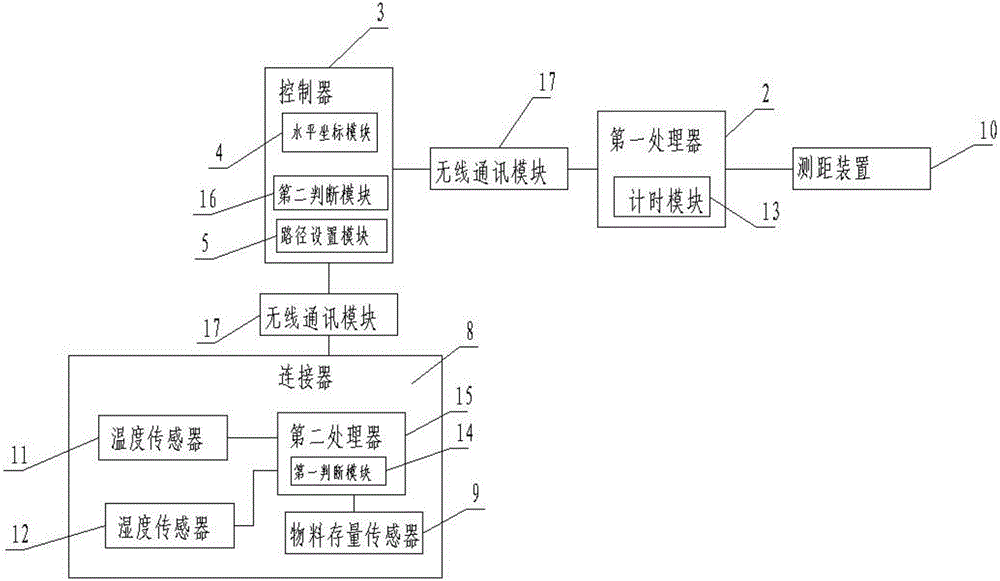

[0022] The control method of the control system of the feeding device of the injection molding machine, such as figure 1 , figure 2 As shown, it includes a crane 1, a first processor 2 installed on the crane 1, a controller 3 connected to the first processor 2, a horizontal coordinate module 4 and a path setting module 5 installed in the controller 3, and a transfer hopper 6. The drying hopper 7, the connector 8 connected to the drying hopper 7, the material stock sensor device 9 provided on the connector 8, also includes the following control methods:

[0023] Step 1, when the material inventory sensing device 9 detects that the material in the drying hopper 7 is lower than the set material inventory value, the controller 3 receives the signal from the material inventory sensing device 9, and the controller 3 receives the signal from the corresponding drying hopper 7. The horizontal coordinate position, the controller 3 determines the horizontal coordinate position of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com